配件详情

麦克福斯约翰迪尔发动机零配件

|

|

|

约翰迪尔 3029 2.9T 活塞(米) RE500211

|

型号 |

数量 |

描述 |

|

TAR67942 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机后油封 |

|

TAT21139 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机止推瓦(标准) |

|

TMX504 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机试剂盒 (4) |

|

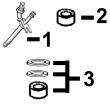

TR504300 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆衬套 PT 32 mm |

|

TR80033 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆螺钉 |

|

TRE27348 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆瓦(标准 |

|

TRE27352 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机主轴瓦(标准) |

|

TRE31617 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机气门密封 STEM LITER ENG |

|

TRE44574 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机前油封 |

|

TRE501578 |

1 |

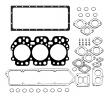

约翰迪尔(John Deere) 强鹿3029 2.9D发动机大修包 |

|

TRE66968 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 |

|

型号 |

数量 |

描述 |

|

TAR67942 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机后油封 |

|

TAT21139 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机止推瓦(标准) |

|

TMX504 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机试剂盒 (4) |

|

TR504300 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆衬套 PT 32 mm |

|

TR80033 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆螺钉 |

|

TRE27348 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆瓦(标准 |

|

TRE27352 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机主轴瓦(标准) |

|

TRE31617 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机气门密封 STEM LITER ENG |

|

TRE44574 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机前油封 |

|

TRE501578 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机大修包 |

|

TRE66968 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机TOK2.9D9A

|

型号 |

数量 |

描述 |

|

TAR67942 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机后油封 |

|

TAT21139 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机止推瓦(标准) |

|

TMX504 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机试剂盒 (4) |

|

TR501124 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆螺钉 |

|

TR504300 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆衬套 PT 32 mm |

|

TRE27348 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆瓦(标准 |

|

TRE27352 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机主轴瓦(标准) |

|

TRE31617 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机气门密封 STEM LITER ENG |

|

TRE44574 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机前油封 |

|

TRE501578 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机大修包 |

|

TRE66968 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈(RE61467) |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机内部修理套件TIK2.9D9

|

型号 |

数量 |

描述 |

|

TAT21139 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机止推瓦(标准) |

|

TR80033 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆螺钉 |

|

TR97341 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机GASKET, OIL PAN 3 CYL |

|

TRE27348 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆瓦(标准 |

|

TRE27352 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机主轴瓦(标准) |

|

TRE31617 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机气门密封 STEM LITER ENG |

|

TRE38850 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机GASKET, CYL HEAD SET |

|

TRE66968 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈(RE61467) |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机TIK2.9D9A

|

型号 |

数量 |

描述 |

|

TAT21139 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机止推瓦(标准) |

|

TR501124 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆螺钉 |

|

TR97341 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机GASKET, OIL PAN 3 CYL |

|

TRE27348 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机连杆瓦(标准 |

|

TRE27352 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机主轴瓦(标准) |

|

TRE31617 |

6 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机气门密封 STEM LITER ENG |

|

TRE38850 |

1 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机GASKET, CYL HEAD SET |

|

TRE66968 |

3 |

约翰迪尔(John Deere) 强鹿3029 2.9D发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈(RE61467) |

|

|

||||||||||||||||||||||||||||||

(1)螺旋齿轮。

(2)将所有R78558带帽螺丝替换为带法兰头帽螺丝TR85363。

(3)套管安装后,在装配活塞销之前,应使机器套管符合连杆的形状。

(4)套件包含TT20094斜齿轮转换为TRE50979曲轴。

(5)使用机器拆分连杆使用TR80033并使用断裂连杆TR501124。

(6)(m)R73604。

(7)(m)R100812,(m)R127337,(m)R127918,(m)R55164。

(8)与断裂分体连杆一起使用。

(9)检查您的应用程序是否正确使用。

(10)凸轮轴有一个40毫米宽的前轴承轴颈,用于转速计驱动的后部压力机,它将取代前轴承轴颈较窄的早期凸轮轴而没有任何问题。取代凸轮轴标志T20015,T20016,R79643,R106957和RE522311。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE523502、RE518520、RE68345、RE53307、RE62240、RE533095、RE502513、RE38009、R30402、RE521538、RE521540、RE62240、P524837、RE60021、RE507236、RE59588、RE549153、RE530870、SE501610、SE501609、RE70960

insert&crankshaft journal. carefully place connecting rod against crankshaft journal. cd,ctm125,073 –19–15jan01–3/5 rg7504 –un–04nov97 tongue-and-groove rod rg9448 –un–27jul98 precision-joint rod a—tang b—groove c—extra groove (not used) note: due to the manufacturing process, precision joint? rod&cap have two grooves each, while bearing inserts have a single tang. the extra grooves (c) are not used. 5. install bearing insert in connecting rod cap with tang (a) in groove (b). precision joint is a trademark of deere & company cd,ctm125,073 –19–15jan01–4/5 cd30574 –un–19may98 6. apply clean engine oil to bearing insert. install cap on connecting rod with tangs (a) to same side. on precision joint? rods, make sure cap is properly aligned on rod with joint surfaces perfectly interlocked. precision joint is a trademark of deere & company ctm125 (14jun01) 10-23 powertech 2.9 l diesel engines 061401 pn=91 continued on next page cylinder block, liners, pistons&rods 10 24 cd,ctm125,073 –19–15jan01–5/5 cd30240 –un–08mar95 cd30239 –un–08mar95 important: never use connecting rod bolts more than once for final engine assembly. once bolts have been tightened to final torque-turn specification, they must not be reused for another final assembly. bolts for precision joint? connecting rods are 3 mm (0.118 in.) shorter than tongue-and-groove bolts. do not mix hardware. 7. dip new connecting rod bolts in clean oil&tighten them alternately to specified torques. specification connecting rod bolts—torque 56 n?m (40 lb-ft) torque turn 90—100 ° 8. torque-turn all bolts to specified angle as follows: ? position the wrench parallel to engine axis (a). ? tighten until the wrench is perpendicular to engine axis (b). 9. check for proper side clearance in all rods. each rod must have a slight side-to-side movement. precision joint is a trademark of deere & company ctm125 (14jun01) 10-24 powertech 2.9 l diesel engines 061401 pn=92 cylinder block, liners, pistons&rods 10 25 cd,ctm125,074 –19–15jan01–1/1 measure piston protrusion cd30575 –un–04may98 cd30005 –un–07feb95 1—centerline of cylinder liner bore 2—piston at “tdc” note: press down on top of piston to remove clearances before measuring piston protrusion. 1. place kjd10123 gauge (with flat side up) on cylinder block so that indicator point rests on block surface. 2. set dial indicator at “zero”. 3. while pressing gauge downward, turn crankshaft until piston is at “tdc” position. 4. piston protrusion should not exceed 0.25 mm (0.010 in.) when kjd10123 is used. specification piston—protrusion above block 0.08—0.35 mm (0.003—0.014 in.) note: if kjd10123 gauge is not available, use a dial indicator. in this case, the piston protrusion should be between 0.08—0.35 mm (0.003--0.014 in.) as specified above. 5. if protrusion is out of specifications, check all concerned parts to determine the cause. ctm125 (14jun01) 10-25 powertech 2.9 l diesel engines 061401 pn=93 cylinder block, liners, pistons&rods 10 26 cd,ctm125,077 –19–01dec97–1/3 complete final assembly cd30576 –un–16jun98 front right view cd30577 –un–16jun98 rear left view 1. re-install all components previously removed. apply following recommendations then perform engine break-in. 2. cylinder block has some orifices which are in relation either with the lubrication/coolant system. when re-assembling an engine, be sure that coolant lines are connected to corresponding coolant ports&oil lines to oil ports. apply torques as indicated. cylinder block plugs&fittings—specification a—coolant drain (1/4“)—torque 17 n?m (13 lb-ft) b—turbocharger oil return (1/2”)—torque . 45 n?m (33 lb-ft) c—1/2“ cyl. for dipstick tube— torque . 67 n?m (50 lb-ft) d—oil galleries (1/8”)—torque . 17 n?m (13 lb-ft) e—1/4“ coolant gallery (side)— torque . 17 n?m (13 lb-ft) f—rear coolant gallery (1”)— torque . 45 n?m (33 lb-ft) g—oil gallery (3/8“)—torque . 45 n?m (33 lb-ft) h—piston cooling jet—torque . 10 n?m (7.5 lb-ft) note: plugs for orifices (a)&(d) are coated with sealant&can be reused several times without addition of sealing compound. 3. be sure that piston cooling jets (h) are installed. 4. check that the steel cap (j) obturating the oil gallery, is installed at the front end for all engines,&at the rear end of engines which have no continuity of oil gallery through the flywheel housing. continued on next page ctm125 (14jun01) 10-26 powertech 2.9 l diesel engines 061401 pn=94 cylinder block, liners, pistons&rods 10 27 cd,ctm125,077 –19–01dec97–2/3 cd551p1 –un–10dec96 5. service cylinder block may have additional side mounting bosses (a). in case where these bosses interfere with the chassis/other machine components, grind concerned area. important: be sure, when grinding, that particles do not enter dipstick hole (b). cd,ctm125,077 –19–01dec97–3/3 cd551p5 –un–07nov96 6. oil gallery ball (a) is provided with service cylinder block, but may not be installed. in this case, proceed as follows: a. put ball (a) in oil passage (b). b. drive in ball using an appropriate driver (c) until ball bottoms. c. check for proper installation. the distance between pan rail&top of ball should be approximatively 54 mm (2.16 in.). ctm125 (14jun01) 10-27 powertech 2.9 l diesel engines 061401 pn=95 cylinder block, liners, pistons&rods 10 28 ctm125 (14jun01) 10-28 powertech 2.9 l diesel engines 061401 pn=96 group 15 crankshaft, main bearings&flywheel 15 1 cd,ctm125,083 –19–16jan01–1/1 remove crankshaft pulley cd30580 –un–04may98 cd30802 –un–20apr01 crankshaft pulley with bolted weight 1. remove pulley attaching cap screw. 2. using jdg410 puller/any other suitable puller, remove pulley from crankshaft. important: do not attempt to remove cap screws (a) holding the unbalancing weights. if a cap screw has been removed by accident, re-install it using loctite?271 high strength thread lock (also available under part number ty9371)&tighten to 50 n?m (35 lb-ft). loctite is a trademark of loctite corp. cd,ctm125,084 –19–16jan01–1/1 install crankshaft pulley cd30581 –un–16jun98 1. install shaft key (a) on crankshaft. 2. position pulley on crankshaft with washer (b)&cap screw (c). 3. tighten to specification. specification pulley-to-crankshaft—torque 150 n?m (110 lb-ft) ctm125 (14jun01) 15-1 powertech 2.9 l diesel engines 061401 pn=97 crankshaft, main bearings&flywheel 15 2 cd,ctm125,085 –19–16jan01–1/1 check pulley wobble (engine with front pto) cd30582 –un–16jun98 a—wobble checking with dial indicator b—pulley c—collet drive d—timing gear cover e—wear sleeve f—o’ring g—crankshaft h—gear j—oil deflector k—front oil seal 1. prior to disassembly, check the following specification: specification crankshaft pulley—max. wobble 0.5 mm (0.02 in.) 2. if wobble (a) exceeds specification, it indicates improper mating of tapered surfaces due to uneven tightening of collet cap screws/damage to one or both the tapered surfaces. cd,ctm125,086 –19–01dec97–1/1 remove pto pulley cd30583 –un–19may98 cd30008 –un–05oct94 1. remove the eight cap screws (a) attaching pulley to collet. 2. using a wooden block&a hammer, tap on pulley until it loosens from conical seat of collet. 3. remove collet attaching cap screw (b). 4. remove collet&pulley. ctm125 (14jun01) 15-2 powertech 2.9 l diesel engines 061401 pn=98 crankshaft, main bearings&flywheel 15 3 cd,ctm125,087 –19–16jan01–1/1 install pto pulley cd30395 –un–10may95 cd30160 –un–05oct94 a—pulley-to-collet bolt b—collet-to-crankshaft bolt c—pulley mark d—timing gear cover mark 1. lightly oil tapered surfaces of collet&pulley. 2. position collet in pulley. install both cap screws (a) 180° apart to keep collet with the pulley. 3. install collet/pulley assembly on the crankshaft with washer&cap screw (b). 4. put cylinder no. 1 at tdc then turn pulley/collet assembly so that external groove mark (c) on pulley is aligned with tdc reference mark on timing cover (d). 5. tighten collet retaining cap screw (b) as specified: specification pulley-to-crankshaft—torque . 150 n?m (110 lb-ft) 6. tighten the two collet cap screws (a) alternately and evenly to specification. 7. install remaining six collet cap screws. again alternately&evenly tighten the two cap screws 90° from the first two cap screws to specification. tighten the remaining cap screws to specification. always tighten collet cap screws in pairs opposite each other. 8. repeat the collet cap screw tightening sequence until all the cap screws have been tightened to the specified torque. specification crankshaft pulley-to-collet bolt—torque . 35 n?m (25 lb-ft) 9. check pulley wobble to ensure that tapered surfaces are mated correctly. ctm125 (14jun01) 15-3 powertech 2.9 l diesel engines 061401 pn=99 crankshaft, main bearings&flywheel 15 4 cd,ctm125,088 –19–01dec97–1/1 flywheel removal rg5632 –un–02apr90 caution: flywheel is heavy. plan a proper lifting procedure to avoid personal injury. 1. remove two cap screws&install guide studs in their place (shown installed) then remove the other cap screws. 2. install two 1/2-13unc/m10 cap screws (length 100 mm/4 in.) into the threaded holes (a) to push flywheel off crankshaft&to facilitate flywheel handling. note: flywheel may not have the handling threaded holes (a). in this case, install two cap screws into clutch system threaded holes then, using a soft hammer, gently tap on flywheel to unstick it. ctm125 (14jun01) 15-4 powertech 2.9 l diesel engines 061401 pn=100 crankshaft, main bearings&flywheel 15 5 cd,3274,g15,8 –19–01mar92–1/1 flywheel ring gear replacement rg3838 –un–14oct88 t90596 –un–14oct88 1. drive ring gear off with a brass drift&hammer. caution: oil fumes/oil can ignite above 190° c (380°f). when heating ring gear, use a thermometer&do not exceed 180°c (360°f). heat the oil in a well ventilated area. plan a safe handling procedure to avoid burns. important: if flame is used to heat ring gear, be sure gear is heated uniformly around circumference. 2. heat new ring gear to 150°c (300°f) using either heated oil, oven heat,/flame heat. 3. tap heated ring gear into place against flywheel shoulder. chamfered edge of teeth (a) must be toward engine. note: be sure complete ring gear circumference is flush against shoulder of flywheel. cd,ctm125,089 –19–16jan01–1/1 install ball bearing rg6345 –un–03aug92 a—27487 driver b—27508 disk c—27493 disk d—ball bearing e—flywheell some flywheels may have a ball bearing (d) to be installed with flywheel removed from engine. drive new ball bearing into engine side of flywheel using 27487 driver (a), 27508 disk (b)&27493 disk (c) from d01045aa/other bearing driver set, until bearing bottoms in bore. check bearing for smooth operation. ctm125 (14jun01) 15-5 powertech 2.9 l diesel engines 061401 pn=101 crankshaft, main bearings&flywheel 15 6 cd,ctm125,090 –19–16jan01–1/1 install flywheel cd7140 –un–07mar95 note: flywheels&crankshafts pulleys are unbalanced and therefore are not interchangeable with 4/6 cyl. engines. several unbalance values are used, take care not to mix parts. use relevant parts catalogs to order appropriate parts. 1. install two guide studs in crankshaft. 2. place flywheel on studs&slide into position against crankshaft. important: always replace flywheel cap screws when flywheel has been removed. 3. install cap screws&washers if requested, then tighten crosswise to specification. specification flywheel bolt—torque . 160 n?m (120 lb-ft) cd,ctm125,094 –19–16jan01–1/4 remove crankshaft rear oil seal cd30584 –un–04may98 the crankshaft rear oil seal (a)&the wear sleeve (b) composes a non-separable part. to remove this oil seal/wear sleeve assembly, the two following procedures can be used depending on special tool availability. ctm125 (14jun01) 15-6 powertech 2.9 l diesel engines 061401 pn=102 continued on next page crankshaft, main bearings&flywheel 15 7 cd,ctm125,094 –19–16jan01–2/4 rg5638 –un–02apr90 rg5639 –un–02apr90 using jdg698a 1. adjust forcing screw on jdg698a tool&position screw so it centers tool on crankshaft flange. 2. use the slots in jdg698a tool as a template, mark three locations on seal casing where screws should be installed for removal purposes. remove tool from crankiest flange. 3. drill a 3/16 in. hole through wear sleeve lip and seal casing at the three marked locations. 4. position jdg698a on end of crankshaft then install three 2-1/2 in. sheet metal screws with washers into slots. evenly tighten screws until plate is flush with rear face of crankshaft. 5. tighten forcing screw until seal&wear sleeve assembly is removed from engine. continued on next page ctm125 (14jun01) 15-7 powertech 2.9 l diesel engines 061401 pn=103 crankshaft, main bearings&flywheel 15 8 cd,ctm125,094 –19–16jan01–3/4 cd30243 –un–06mar95 cd30244 –un–06mar95 using jdg645e 1. place¢er jdg645e cap screws&driver plate assembly onto crankshaft rear face. then, using snap ring pliers, set the thinner shoulder of ring tool between sleeve flange&seal case. 2. secure the assembly with a clamp then gradually tighten the screw until wear sleeve is extracted. cd,ctm125,094 –19–16jan01–4/4 cd30396 –un–10may95 cd30247 –un–06mar95 cd30397 –un–10may95 3. cut the rubber lip now accessible&remove it. 4. using a punch&a hammer, tap the seal case toward engine at any location until seal case pivots. 5. using jdg22 slide hammer puller, extract seal case. ctm125 (14jun01) 15-8 powertech 2.9 l diesel engines 061401 pn=104 crankshaft, main bearings&flywheel 15 9 cd,ctm125,095 –19–16jan01–1/1 flywheel housing replacement cd30585 –un–16jun98 cd7141 –un–23may95 a—3/8 in. cap screw b—5/8 in. cap screw c—gasket caution: flywheel housing weighs 20 to 40 kg (43 to 86 lb.). 1. remove flywheel&oil pan. 2. remove the four cap screws (b)&the eight 3/8 in. cap screws (a), then remove flywheel housing. 3. clean mating surfaces&install new gasket (c). 4. install flywheel housing&cap screws. tighten as specified. specification 3/8 in. cap screw—torque (1st stage) . 30 n?m (23 lb-ft) torque (2nd stage) 50 n?m (35 lb-ft) 5/8 in. cap screw—torque 230 n?m (170 lb-ft) note: on certain application, the open holes need to be obturated. apply sealing compound on threads of cap screws. cd,ctm125,097 –19–16jan01–1/2 install oil seal/wear sleeve cd30586 –un–16jun98 note: due to a diameter change of the crankshaft bore, it may be necessary to suppress the pilot pin (a) from kcd10002 tool. with this modification kcd10002 becomes kcd10002a. continued on next page ctm125 (14jun01) 15-9 powertech 2.9 l diesel engines 061401 pn=105 crankshaft, main bearings&flywheel 15 10 cd,ctm125,097 –19–16jan01–2/2 t81204 –un–01nov88 t81205 –un–07nov88 1. position the guide plate from jt30040b or kcd10002a tool over dowel with two cap screws. finger tighten both cap screws until they contact the pilot. 2. using the oil seal/wear sleeve assembly with open side toward engine, center the guide plate and tighten cap screws. 3. slide driver onto guide&gradually tighten the cap screw/nut until driver bottoms. ctm125 (14jun01) 15-10 powertech 2.9 l diesel engines 061401 pn=106 crankshaft, main bearings&flywheel 15 11 cd,ctm125,098 –19–16jan01–1/1 crankshaft end play measure cd30220 –un–07mar95 cd7144 –un–07mar95 a—oversized thrust washers b—front of engine c—rear bearing cap side note: it is recommended to measure crankshaft end play prior to removing crankshaft to determine condition of thrust bearings. check crankshaft end play using a dial indicator and compare with specifications. crankshaft—specification 2-piece thrust bearing—end play . 0.13—0.40 mm (0.005—0.016 in.) wear tolerance . 0.50 mm (0.02 in.) 5/6-piece thrust bearing—end play 0.03—0.35 mm (0.001—0.014 in.) wear tolerance . 0.50 mm (0.02 in.) if end play is still not within specification with new standard 2-piece/6-piece thrust bearings, install a 5-piece thrust bearing with oversized thrust washers. specification oversized crankshaft thrust washer—thickness . + 0.18 mm (0.007 in.) note: oversized thrust bearing set contains three 0.18 mm (0.007 in.) oversized thrust washers to be installed as shown. cd,ctm125,099 –19–01dec97–1/1 remove crankshaft cd30587 –un–04may98 1. identify main bearing caps to assure correct placement during reassembly. 2. attach nylon slings (or other suitable lifting slings) to crankshaft. 3. carefully lift crankshaft out of cylinder block. ctm125 (14jun01) 15-11 powertech 2.9 l diesel engines 061401 pn=107 crankshaft, main bearings&flywheel 15 12 cd,3274,g15,19 –19–01mar92–1/1 crankshaft inspection cd7147 –un–23feb89 1. clean crankshaft thoroughly, especially oil passages from crankshaft bearings to connecting rod bearings. 2. check crankshaft for cracks/signs of load stress (see illustration for critical areas of load stress in a crankshaft). 3. inspect both shoulders of thrust bearing journal for scores/unevenness. ctm125 (14jun01) 15-12 powertech 2.9 l diesel engines 061401 pn=108 crankshaft, main bearings&flywheel 15 13 cd,ctm125,100 –19–16jan01–1/1 check crankshaft journal diameter cd30588 –un–04may98 cd7149 –un–07mar95 1. measure diameter of all crankshaft journals at several points around journal&compare with specifications. specification crankshaft main journal— diameter (standard) 79.324—79.350 mm (3.123—3.124 in.) . crankshaft rod journal— diameter (standard) 69.799—69.825 mm (2.748—2.749 in.) . crankshaft main/rod journal—maximum taper . 0.03 mm (0.0012 in.) maximum out-of-roundness . 0.075 mm (0.003 in.) 2. install main bearing inserts&caps then tighten cap screws to 135 n?m (100 lb-ft), then measure diameter of main bearing (assembled)&compare with specification. specification crankshaft main bearings assembled—diameter 79.396—79.440 mm (3.126—3.127 in.) crankshaft main bearing-to-journal—oil clearance 0.046—0.116 mm (0.0018—0.0046 in.) maximum wear 0.15 mm (0.006 in.) note: the crankshaft main bearing-to-journal oil clearance can also be determined using plastigage?. if engine had a previous major overhaul and undersized bearing inserts were used, diameters listed above may not be the same as those recorded. however, the bearing clearance should be within specifications. 3. if crankshaft journal diameter/clearance are not within specifications, replace crankshaft/regrind journals to match undersize bearings (see “regrind crankshaft” in this group). note: undersize crankshafts may be also available through regular service parts channel. plastigage is a trademark of dana corp. ctm125 (14jun01) 15-13 powertech 2.9 l diesel engines 061401 pn=109 crankshaft, main bearings&flywheel 15 14 cd,ctm125,101 –19–16jan01–1/1 determine crankshaft main bearing clearance using plastigage? cd7145 –un–23may95 1. place a strip of plastigage? in the center of the bearing. 2. install cap&tighten cap screws to 135 n?m (100 lb-ft). 3. remove cap&compare the width of plastigage? with scale provided on side of package to determine clearance. 4. maximum permissible clearance is 0.15 mm (0.006 mm). plastigage is a trademark of dana corp. cd,ctm125,102 –19–16jan01–1/1 regrind crankshaft if journals are worn, tapered, out-of-round, scored or damaged, the crankshaft journals can be reground and correct undersize bearing inserts installed. specification undersized crankshaft main bearing—1st size 0.25 mm (0.01 in.) 2nd size . 0.50 mm (0.02 in.) 3rd size 0.76 mm (0.03 in.) important: crankshaft grinding should be carried out only by experienced personnel on equipment capable of maintaining crankshaft size and finish specifications. note: this cast iron crankshaft can be reground only once to 0.25 mm (0.01 in.) under standard size. crankshaft must be lapped afterwards according to the micro-finishing specifications given in this group. ctm125 (14jun01) 15-14 powertech 2.9 l diesel engines 061401 pn=110 crankshaft, main bearings&flywheel 15 15 cd,ctm125,103 –19–01dec97–1/1 crankshaft regrinding guidelines if the crankshaft is to be reground, use the following recommended guidelines: 1. determine the size to which the journals are to be reground according to the measures taken during inspections. 2. if one/more main/connecting rod journals require grinding, then grind all of the main journals or all of the connecting rod journals to the same required size. grind clockwise (as viewed from nose of crankshaft). 3. care must be taken to avoid localized heating which often produces grinding cracks. use coolant generously to cool the crankshaft while grinding. do not crowd the grinding wheel into the work. 4. polish/lap (clockwise) the ground surfaces to the specified finish (see “micro-finishing specifications” in this group). the reground journals will be subject to excessive wear unless polished smooth. note: when thrust surfaces are reground&an oversize washer is used, crankshaft end play specification must be maintained. 5. if the thrust surfaces of the crankshaft are worn or grooved excessively, they must be reground and polished. an oversize thrust washer set is available. 6. stone the edge of all oil holes in the journal surfaces smooth to provide a radius of approximately 1.50 mm (0.060 in.). 7. after grinding has been completed, inspect the crankshaft by the fluorescent magnetic particle method,/other similar method to determine if cracks have originated due to the grinding operation. 8. de-magnetize the crankshaft. 9. thoroughly clean the crankshaft&oil passages with solvent. dry with compressed air. ctm125 (14jun01) 15-15 powertech 2.9 l diesel engines 061401 pn=111 crankshaft, main bearings&flywheel 15 16 cd,3274,g15,37 –19–16jan01–1/1 micro-finishing specifications the following specifications are required when cast iron crankshafts have to be reground: specification crankshaft micro-finishing specifications—center line average (c.l.a.) 0.2 micron (8 micro-in.) or better skewness parameter (sk) . negative bearing ratio (tp) with 1% tp reference line at a depth of 0.22 micron (8.8 micro-in.) tp more than 20% bearing ratio (tp) with 1% tp reference line at a depth of 0.38 micron (15.2 micro-in.) tp more than 80% bearing ratio (tp) with 1% tp reference line at a depth of 0.64 micron (25.6 micro-in.) tp more than 90% final journal finishing operation must be done in clockwise direction (as viewed from nose of crankshaft). important: do not attempt to regrind cast iron crankshafts if above specifications cannot be obtained. cd,ctm125,104 –19–16jan01–1/2 replace crankshaft gear rg7238 –un–10oct94 e—d01218aa pulling attachment f—disc g—d01200aa push puller note: gear can be replaced with crankshaft not removed from engine. 1. pull gear using d01200aa push puller&d01218aa pulling attachment/any other suitable puller. 2. remove woodruff key from crankshaft&remove any burrs from gear journal. 3. install a new woodruff key in crankshaft keyway. caution: oil fumes/oil can ignite above 190°c (380°f). use a thermometer to ensure that a temperature of 180°c (360°f) is not exceeded. do not allow a flame/heating element to come into direct contact with the oil. heat the oil in a well-ventilated area. plan a safe handling procedure to avoid burns. 4. heat new gear to 180°c (360°f). ctm125 (14jun01) 15-16 powertech 2.9 l diesel engines 061401 pn=112 continued on next page crankshaft, main bearings&flywheel 15 17 cd,ctm125,104 –19–16jan01–2/2 cd30398 –un–10may95 5. drive gear, with chamfered side toward engine, onto crankshaft using jdg794a driver (formerly jdh7 or jdg794). cd,ctm125,105 –19–01dec97–1/1 install main bearing inserts cd30589 –un–19may98 a—bearing insert tang b—cylinder block slot install main bearing inserts, making sure that tang (a) on the inserts engages in slot (b) in cylinder block&main bearing caps. also ensure that oil bores of bearing inserts are aligned with oil passages in cylinder block. cd,ctm125,106 –19–01dec97–1/1 install 2-piece thrust bearing cd30590 –un–04may98 install one thrust bearing (a) from 2-piece thrust bearing set in rear web of cylinder block&the other in rear bearing cap. ctm125 (14jun01) 15-17 powertech 2.9 l diesel engines 061401 pn=113 crankshaft, main bearings&flywheel 15 18 cd,ctm125,107 –19–01dec97–1/1 install 6-piece thrust bearing cd30399 –un–10may95 a—oil grooves install two thrust washers in the block&two on bearing cap. the oil grooves (a) must face towards crankshaft thrust surfaces. note: engine may be equipped with a 5-piece thrust bearing from the factory. if this 5-piece thrust bearing is re-installed, place two thrust washers on bearing cap&the last one on rear face of cylinder block. ctm125 (14jun01) 15-18 powertech 2.9 l diesel engines 061401 pn=114 crankshaft, main bearings&flywheel 15 19 cd,ctm125,108 –19–16jan01–1/1 crankshaft installation t88557 –un–14oct88 cd30250 –un–06mar95 1. apply a liberal coating of clean engine oil to bearing surfaces&crankshaft journals&install crankshaft. 2. dip all main bearing cap screws in clean engine oil and position them with washers in the bearing caps. 3. install all bearing caps (b) according to the identification marks stamped on them,&so that tangs (a) of both bearing halves are on the same side. install all cap screws finger-tight. 4. apply a first torque not exceeding 20 n?m (14 lb-ft). 5. using a soft-face hammer, move crankshaft first towards the rear&then towards the front to align the rear thrust washers. important: before tightening rear cap screws, ensure that rear thrust washer of cap is aligned with rear thrust washer of block. 6. tighten all cap screws to specification. specification crankshaft main bearing bolt— torque . 135 n?m (100 lb-ft) 7. check for free rotation&end play of the crankshaft. ctm125 (14jun01) 15-19 powertech 2.9 l diesel engines 061401 pn=115 crankshaft, main bearings&flywheel 15 20 ctm125 (14jun01) 15-20 powertech 2.9 l diesel engines 061401 pn=116 group 20 camshaft&timing gear train 20 1 cd03523,00000f7 –19–17jan01–1/1 remove crankshaft front oil seal cd30804 –un–17apr01 cd30803 –un–17apr01 1. remove crankshaft pulley. 2. make a hole on outer case of oil seal using a punch (or a nail). 3. using jdg22 slide hammer puller with a self-thread screw, pull off oil seal. 4. if necessary, repeat this operation at 120° apart. cd03523,00000f8 –19–17jan01–1/1 remove timing gear cover cd30805 –un–12mar01 a—alternator b—water pump c—oil pan d—crankshaft pulley e—oil pressure regulating valve f—timing gear cover 1. remove alternator (a). 2. remove water pump (b). 3. remove oil pan (c). 4. remove crankshaft pulley (d). 5. remove oil pressure regulating valve (e). 6. remove timing gear cover (f). 7. if not yet done, remove oil seal from timing gear cover. ctm125 (14jun01) 20-1 powertech 2.9 l diesel engines 061401 pn=117 camshaft&timing gear train 20 2 cd,ctm125,112 –19–17jan01–1/2 measure timing gear backlash cd30591 –un–04may98 a—camshaft/upper idler gear b—injection pump/upper idler gear c—upper idler/crankshaft gear d—crankshaft/lower idler gear e—oil pump/lower idler gear measure backlash between gears using a dial indicator and compare with specifications. helical timing gear—specification upper idler/crankshaft gear— backlash 0.07—0.30 mm (0.003—0.012 in.) wear tolerance . 0.40 mm (0.016 in.) upper idler/camshaft gear— backlash 0.07—0.35 mm (0.003—0.014 in.) wear tolerance . 0.51 mm (0.020 in.) upper idler/injection pump gear— backlash 0.07—0.35 mm (0.003—0.014 in.) wear tolerance . 0.51 mm (0.020 in.) lower idler/crankshaft gear— backlash 0.07—0.35 mm (0.003—0.014 in.) wear tolerance . 0.51 mm (0.020 in.) lower idler/oil pump gear— backlash 0.04—0.38 mm (0.0016—0.015 in.) . wear tolerance . 0.40 mm (0.016 in.) spur timing gear engines for 5300/5300n tractors ( -242551cd) all other engines ( -270818cd) —specification upper idler/crankshaft gear— backlash 0.04—0.35 mm (0.0016—0.014 in.) . wear tolerance . 0.60 mm (0.024 in.) upper idler/camshaft gear— backlash 0.08—0.45 mm (0.003—0.018 in.) wear tolerance . 0.85 mm (0.033 in.) upper idler/injection pump gear— backlash 0.08—0.45 mm (0.003—0.018 in.) wear tolerance . 0.85 mm (0.033 in.) lower idler/crankshaft gear— backlash 0.04—0.35 mm (0.0016—0.014 in.) . wear tolerance . 0.65 mm (0.025 in.) lower idler/oil pump gear— backlash 0.08—0.40 mm (0.003—0.016 in.) wear tolerance . 0.75 mm (0.030 in.) camshaft/aux. drive gear— backlash 0.09—1.24 mm (0.0035—0.049 in.) . wear tolerance . 1.34 mm (0.053 in.) ctm125 (14jun01) 20-2 powertech 2.9 l diesel engines 061401 pn=118 continued on next page camshaft&timing gear train 20 3 cd,ctm125,112 –19–17jan01–2/2 spur timing gear engines for 5300/5300n tractors (242552cd- ) all other engines (270819cd- ) —specification upper idler/crankshaft gear— backlash 0.01—0.49 mm (0.0004—0.019 in.) . upper idler/camshaft gear— backlash 0.01—0.52 mm (0.0004—0.020 in.) . upper idler/injection pump gear— backlash 0.01—0.52 mm (0.0004—0.020 in.) . lower idler/crankshaft gear— backlash 0.01—0.46 mm (0.0004—0.018 in.) . lower idler/oil pump gear— backlash 0.01—0.49 mm (0.0004—0.019 in.) . camshaft/aux. drive gear— backlash 0.01—0.54 mm (0.0004—0.021 in.) . if backlash is not correct, install new gears. cd,3274,g20,6 –19–17jan01–1/1 camshaft end play measure cd7104 –un–07mar95 using a dial indicator, check camshaft end play. specification camshaft—end play . 0.08—0.23 mm (0.003—0.009 in.) maximum wear . 0.38 mm (0.015 in.) thrust plate—thickness 3.935—3.985 mm (0.155—0.157 in.) . maximum wear . 3.8 mm (0.15 in.) note: if end play exceeds specifications then check thickness of thrust plate as this determines end play. ctm125 (14jun01) 20-3 powertech 2.9 l diesel engines 061401 pn=119 camshaft&timing gear train 20 4 cd,ctm125,113 –19–01dec97–1/1 remove camshaft cd30593 –un–04may98 cd30592 –un–19may98 note: mark parts so that they can be reinstalled in their original positions. 1. remove cylinder head, cam followers&fuel pump. 2. remove cap screws (a)&pull camshaft straight out. important: when removing camshaft, be careful that lobes do not damage the bearing surfaces in bores. note: camshaft can be removed from engine without removing cylinder head by holding cam followers away from camshaft lobes with d15001nu magnetic holding set. cd,ctm125,114 –19–17jan01–1/1 measure camshaft journal cd30594 –un–04may98 specification camshaft journal—diameter 55.872—55.898 mm (2.1997—2.2007 in.) maximum wear . 55.85 mm (2.199 in.) camshaft journal-to-bore—max. clearance 0.18 mm (0.007 in.) if diameter/clearance are not within specifications, replace camshaft. important: to keep the initial working condition between cam lobes&cam followers, always replace cam followers when installing a new camshaft. ctm125 (14jun01) 20-4 powertech 2.9 l diesel engines 061401 pn=120 camshaft&timing gear train 20 5 cd,3274,g20,9 –19–17jan01–1/1 measure height of cam lobe t81262 –un–01nov88 measure longest&shortest diameter of each cam. subtract shorter diameter from longer diameter to find the height of the cam lobe. if any lobe is not of the correct height, install a new camshaft. specification camshaft intake lobe—height . 6.93—7.42 mm (0.273—0.292 in.) maximum wear . 6.68 mm (0.263 in.) camshaft exhaust lobe—height 6.76—7.26 mm (0.266—0.286 in.) maximum wear . 6.50 mm (0.256 in.) important: to keep the initial working condition between cam lobes&cam followers, always replace cam followers when installing a new camshaft. cd,ctm125,115 –19–01dec97–1/1 replace camshaft gear cd30595 –un–19may98 1. remove gear from camshaft using a press. 2. install shaft key on camshaft nose. 3. install gear with timing mark (a) away from camshaft. 4. press gear on shaft until flush with shoulder on camshaft. cd,3274,g20,11 –19–10mar92–1/1 tachometer pick-up pin removal cd30200 –un–07mar95 1. drill&tap an extraction hole of approx. 6 mm (0.250 in.) diameter&12 mm (0.500 in.) depth in center of pin. 2. using a self-made puller (spacer, washer, screw), pull out the tachometer pick-up pin. ctm125 (14jun01) 20-5 powertech 2.9 l diesel engines 061401 pn=121 camshaft&timing gear train 20 6 cd,ctm125,116 –19–17jan01–1/1 install camshaft cd30596 –un–16jun98 1. before installation of the tachometer drive shaft (a), check the diameter of the knurled shaft area (b). if diameter exceeds 12.92 mm (0.5087 in.), rework shaft to 12.88—12.92 mm (0.5071—0.5087 in.). 2. coat camshaft with clean engine oil. on engines with camshaft bushing, lubricate the inner circumference of bushing with ty63331 grease. 3. install camshaft&thrust plate (c) in cylinder block. 4. install cap screws (d)&tighten to specification. specification camshaft thrust plate cap screws—torque 50 n?m (35 lb-ft) important: to keep the initial working condition between cam lobes&cam followers, always replace cam followers (e) when installing a new camshaft. 1available as service part. ctm125 (14jun01) 20-6 powertech 2.9 l diesel engines 061401 pn=122 camshaft&timing gear train 20 7 cd,ctm125,117 –19–17jan01–1/1 check cam follower rg6324 –un–23nov97 measure cam follower diameter&compare with specification. specification cam follower—diameter 31.62—31.64 mm (1.124—1.246 in.) . cam follower-to-bore— clearance 0.06—0.13 mm (0.002—0.005 in.) if diameter/clearance are not within specifications/if the follower face is flat/concave, replace cam follower. cd,3274,g20,20 –19–17jan01–1/1 idler gear end play measure cd7155 –un–23may95 using a dial indicator, check end play of upper&lower idler gears. specification upper&lower idler gear—end play 0.14—0.29 mm (0.006—0.012 in.) maximum wear . 0.40 mm (0.016 in.) ctm125 (14jun01) 20-7 powertech 2.9 l diesel engines 061401 pn=123 camshaft&timing gear train 20 8 cd,ctm125,118 –19–17jan01–1/2 remove front plate cd30186 –un–07mar95 1. proceed as follows in case of front plate replacement: important: replacement front plates do not have any injection pump timing marks. it is extremely important that the timing be accurately transferred from original front plate to the replacement plate in the exact location for proper injection pump timing. a. build an aluminum template as shown under “self-manufactured tool”. b. attach template to previous front plate using three 3/8 in. cap screws&transfer timing mark from previous front plate (a) to template (b) with a pencil. c. attach template to new front plate&transfer timing mark to the new front plate (c) using a scriber. cd,ctm125,118 –19–17jan01–2/2 cd30597 –un–19may98 cd30598 –un–04may98 2. remove upper&lower idler gears. 3. remove camshaft, fuel injection pump&oil pump. 4. remove countersunk screws (a)&lift off front plate. 5. remove oil by-pass valve&spring (b). ctm125 (14jun01) 20-8 powertech 2.9 l diesel engines 061401 pn=124 camshaft&timing gear train 20 9 cd,3274,g20,22 –19–01feb94–1/1 idler gear bushing&shaft measure cd7160 –un–07mar95 cd7159 –un–07mar95 specification upper idler gear shaft (helical gear)—diameter 44.437—44.463 mm (1.7495—1.7505 in.) lower idler gear shaft (helical and spur gear)—diameter 44.437—44.463 mm (1.7495—1.7505 in.) upper idler gear shaft (spur gear)—diameter 69.759—69.775 mm (2.7464—2.747 in.) upper idler gear bushing (helical gear)—diameter 44.501—44.527 mm (1.752—1.753 in.) lower idler gear bushing (helical and spur gear)—diameter 44.501—44.527 mm (1.752—1.753 in.) . upper idler gear bushing (spur gear)—diameter 69.827—69.857 mm (2.7491—2.7503 in.) upper idler gear bushing-to-shaft (helical gear)—clearance 0.038—0.09 mm (0.0015—0.0035 in.) . maximum wear . 0.15 mm (0.006 in.) lower idler gear bushing-to-shaft (helical&spur gear)— clearance 0.038—0.09 mm (0.0015—0.0035 in.) . maximum wear . 0.15 mm (0.006 in.) upper idler gear bushing-to-shaft (spur gear)—clearance 0.052—0.098 mm (0.002—0.0038 in.) maximum wear . 0.15 mm (0.006 in.) if clearance is more than specified, replace worn parts with new ones. ctm125 (14jun01) 20-9 powertech 2.9 l diesel engines 061401 pn=125 camshaft&timing gear train 20 10 cd,3274,g20,23 –19–17jan01–1/1 idler gear bushing replacement cd7161 –un–07mar95 note: bushing for spur upper idler gear is not available separately. install a new idler gear/bushing assembly. 1. press worn idler gear bushing out of gear. important: the upper&lower idler gears require different bushings. upper idler gear: being pressure lubricated, this gear is specified with a smooth-bore bushing. lower idler gear: being splash lubricated, this gear is specified with a lube-groove fitted bushing. 2. press in new bushing with jd-252 driver&jdg537 handle so that it is flush with one side of the gear. cd,ctm125,119 –19–01dec97–1/1 remove idler shaft cd30599 –un–04may98 remove upper/lower idler shaft by driving shaft out of the front plate. remove thrust washer. ctm125 (14jun01) 20-10 powertech 2.9 l diesel engines 061401 pn=126 camshaft&timing gear train 20 11 cd,ctm125,132 –19–17jan01–1/1 install idler shaft spring pin rg6459 –un–26oct92 cd30401 –un–10may95 c—pin protrusion d—thrust washer ears e—countersunk screw f—shaft oil holes note: the upper idler shaft for engine with auxiliary drive (spur gear) has a spring pin to allow a proper orientation of the shaft oil holes (f) and of the thrust washer ears (d) to clear space around countersunk front plate screw (e). press spring pin until protrusion (c) is obtained. specification upper shaft spring pin (spur gear)—protrusion (c) . 7.5—8.5 mm (0.295—0.335 in.) ctm125 (14jun01) 20-11 powertech 2.9 l diesel engines 061401 pn=127 camshaft&timing gear train 20 12 cd,ctm125,133 –19–01dec97–1/1 install idler shafts cd30255 –un–06mar95 upper idler shaft cd30256 –un–06mar95 lower idler shaft important: oil hole in upper idler shaft must be properly indexed to provide adequate lubrication to idler gear bushing. 1. install thrust washer with sharp edge toward front plate. 2. place idler shaft in front plate bore with oil hole oriented between 10&11 o’clock position. on engine with auxiliary drive, make sure that spring pin of upper shaft is in line with thrust washer and front plate holes. 3. press shaft into front plate until thrust washer is fully seated. note: idler shaft is secured to front plate when gear bolt/nut are tightened. ctm125 (14jun01) 20-12 powertech 2.9 l diesel engines 061401 pn=128 camshaft&timing gear train 20 13 cd03523,00000f9 –19–17jan01–1/1 front plate gasket cd30712 –un–22feb99 earlier engines ( -291260cd) cd30713 –un–22feb99 later engines (291261cd- ) cd30714 –un–22feb99 gasket for engines ( -291260cd) cd30715 –un–22feb99 gasket for all engines the shape of the oil groove casting (a) used to lubricate the upper idler gear has been modified from engine serial number (291261cd- ). the front plate gasket designed for the new oil groove shape can be used on cylinder blocks with previous oil groove design while previous gasket cannot match the new cylinder block design. ctm125 (14jun01) 20-13 powertech 2.9 l diesel engines 061401 pn=129 camshaft&timing gear train 20 14 cd,ctm125,120 –19–17jan01–1/1 install front plate cd30600 –un–16jun98 cd30597 –un–19may98 cd30598 –un–04may98 cd30695 –un–16jun98 a—countersunk screw b—oil by-pass valve c—stud location d—at21191 plug (5/16“) - qty: 6 e—at22919 plug (3/8”) - qty: 2 f—t23442 stud - qty: 3 g—r79854 bushing h—gasket j—front plate 1. install injection pump stud (f) on front plate using loctite 271. note: standard front plate (without auxiliary drive extension) have several injection pump stud locations. use holes marked (c). 2. on standard front plate only, install the 5/16“ plugs (d) and the 3/8” plugs (e) as shown. bushing (g) is not required for this application. 3. install oil by-pass valve (b)&spring in cylinder block. 4. install gasket (h)&front plate. place new external tooth washers onto countersunk screws (a) then tighten to specification. specification front plate countersunk screws— torque . 35 n?m (25 lb-ft) important: cut off protruding edge of gasket only after timing gear cover has been tightened. ctm125 (14jun01) 20-14 powertech 2.9 l diesel engines 061401 pn=130 camshaft&timing gear train 20 15 cd,ctm125,123 –19–01dec97–1/3 install upper timing gear train cd30601 –un–19may98 1. adjust no. 1 piston to tdc using jde83/jdg820 (formerly jde81-1) flywheel turning tool and jde81-4 timing pin. note: use jde83 on engines with a 142 tooth flywheel ring gear&a flywheel housing tool guide bore of 26.5 mm (1.04 in.) diameter. use jdg820 on engines with a 129 tooth flywheel ring gear&a flywheel housing tool guide bore of 29.9 mm (1.18 in.) diameter. 2. install camshaft then, with jd-254a timing tool on crankshaft nose&directed toward center of camshaft, turn camshaft until gear timing mark (a) aligns with timing tool. cd,ctm125,123 –19–01dec97–2/3 cd30602 –un–19may98 3. install fuel injection pump. 4. using jd-254a timing tool, align the timing mark “3” (for 3 cyl. engines) with the timing tool. continued on next page ctm125 (14jun01) 20-15 powertech 2.9 l diesel engines 061401 pn=131 camshaft&timing gear train 20 16 cd,ctm125,123 –19–01dec97–3/3 cd30603 –un–16jun98 cd30604 –un–19may98 5. lubricate shaft&gear bushing with ty6333 grease1 (a). 6. install idler gear on shaft without turning camshaft gear/injection pump gear. on engine with spur gear, use jdg791a pilot tool (c) to guide gear onto shaft. install upper idler gear with part number visible. 7. install washer, with sharp edge toward timing cover, and bolt (b) then tighten to specification. specification upper idler gear cap screw— torque 110 n?m (80 lb-ft). 8. recheck gear timing to make sure it is correct. 1available as service part. cd,ctm125,124 –19–17jan01–1/1 install lower timing gear train cd30605 –un–04may98 1. install oil pump&lower idler gear. 2. install new bolt with washer (a) from oil pump side. install thrust washer, with sharp edge toward timing cover,&new nut then tighten to specification. specification lower idler gear nut—torque 110 n?m (80 lb-ft). 3. install oil pump gear on pump shaft, tighten hex. nut to specification&secure with three center punch marks. specification oil pump drive gear nut—torque . 75 n?m (55 lb-ft) ctm125 (14jun01) 20-16 powertech 2.9 l diesel engines 061401 pn=132 camshaft&timing gear train 20 17 cd,ctm125,126 –19–01dec97–1/1 install oil deflector cd30608 –un–04may98 install oil deflector (a)&o-ring (b) when equipped, on crankshaft nose. cd,ctm125,125 –19–01dec97–1/1 timing gear cover identification cd30606 –un–04may98 standard timing gear cover cd30607 –un–04may98 timing gear cover with auxiliary drive two types of timing gear covers are used: standard cover. made of aluminum, it can receive the oil filler neck (a)&the tachometer sen*** (b) in relation either with upper timing gear internal teeth or with injection pump drive gear teeth. cover for auxiliary drive. made of aluminum. this cover has an extended area to cover the auxiliary drive gear&can receive a tachometer sen*** (b) located on the side, in relation with injection pump drive gear teeth. this cover can also receive the oil filler neck (a). ctm125 (14jun01) 20-17 powertech 2.9 l diesel engines 061401 pn=133 camshaft&timing gear train 20 18 cd,ctm125,128 –19–17jan01–1/2 install timing gear cover cd30609 –un–16jun98 1 .17—timing gear cover-to-front plate cap screws (in sequence) 18 .23—oil pan-to-timing gear cover cap screws (in sequence) a—magnetic pick-up b—injection pump drive gear nut access plug c—oil pressure regulating valve plug 1. install new gasket on front plate. 2. install cover on engine&apply the following torques in sequence. aluminum timing gear cover—specification magnetic pick-up—torque 15 n?m (11 lb-ft) injection pump drive gear nut access plug—torque . 30 n?m (22 lb-ft) oil pan to timing gear cover, cap screws (18—23)—torque . 50 n?m (35 lb-ft) timing gear cover to front plate, cap screws (1—17)—torque 50 n?m (35 lb-ft) oil pressure regulating valve plug—torque . 95 n?m (70 lb-ft) cd,ctm125,128 –19–17jan01–2/2 cd30610 –un–04may98 3. install oil filler neck/obturation plate then tighten cap screws (a) to specification. specification aluminium oil filler neck—torque . 50 n?m (35 lb-ft) composite oil filler neck—torque . 30 n?m (22 lb-ft) obturation plate for oil filler orifice—torque 50 n?m (35 lb-ft) 4. cut off protruding edge of gasket. ctm125 (14jun01) 20-18 powertech 2.9 l diesel engines 061401 pn=134 camshaft&timing gear train 20 19 cd,ctm125,129 –19–17jan01–1/1 install crankshaft front oil seal cd30611 –un–04may98 cd30698 –un–16jun98 1. place new seal onto kjd10164 seal installer (a) with open side toward engine, then slide the assembly onto crankshaft nose. 2. install pulley cap screw with washer (b), then tighten until driver bottoms. note: kjd10164 tool set contains also a spacer (c) to be used only on old applications with short nose crankshaft (35 mm length). cd,ctm125,130 –19–01dec97–1/1 install wear ring cd30612 –un–04may98 1. when equipped, install the wear ring with chamfered side (a) toward engine. be sure that the o-ring is in place against the oil deflector. 2. install shaft key. ctm125 (14jun01) 20-19 powertech 2.9 l diesel engines 061401 pn=135 camshaft&timing gear train 20 20 cd,ctm125,131 –19–17jan01–1/1 install auxiliary equipment cd30613 –un–16jun98 cd30354 –un–03feb93 a—acces***y gear b—nut c—cap screw/nut 1. install shaft key&gear (a) onto acces***y shaft. tighten nut (b) to specification then, if equipped, bend tabs of washer up against nut. 2. install acces***y with gasket on engine (arrow). 3. tighten the two fastening cap screws/nuts (c) to specification. auxiliary equipment driven by camshaft gear 昆明盘龙CAT3306柴油机配件弯管接头8N-1149快捷的交货方式,甘南玛曲县卡特彼勒9M-197411提供在线购买,河北承德宽城珀金斯P880E发动机滤清器详细参数,山西吕梁岚县沃尔沃增压器8485567折特卖,

阿坝若尔盖县CAT3408柴油机配件水泵总成137-1338谁知道多少钱,遂宁大英县卡特挖掘机共轨喷油器规格型号及价格查询?,庆阳正宁县沃尔沃发电机充电机联系方式?,株洲天元帕维奇拖拉机404D-22柴油发动机油封批发商,山西晋中珀金斯发动机气门正品配件,

bielle/coussinets, code 4802,4803 pleuelstange/lager, kode 4802,4803 biella/cuscinetto, codice 4802,4803 biela/cojinetes, codigo 4802,4803 vevstake/lager, koden 4802,4803 cd40214 -un-23may95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 re21076 connecting rod 4 x (marked r80034) (4802) re42733 connecting rod 4 x (marked r113612) (4803) 2 r80033 screw 2 x x 3 re63914 piston pin ar x re63913 piston pin ar x 4 m41029 snap ring 8 x packg (6) (4802) r54114 snap ring 8 x packg (6) (4803) 5 - piston pin 4 x od 35mm (1-37"), ord re63914 (4802) - piston pin 4 x od 41mm (1-62"), ord re63913 (4803) 6 - bushing 4 x ord re63914 (4802) - bushing 4 x ord re63913 (4803) 7 re27348 kit 4 -101582 x x (a) (kit (2) r83379) id std re27349 kit ar -101582 x x (a) (kit (2) r87748) us -0-254mm (0-01") re27358 kit ar -101582 x x (a) (kit (2) r87754) us -0-508mm (0-02") re27364 bearing kit ar -101582 x x (a) (kit (2) r87757) us -0-762mm (0-03") at21138 bearing 4 101583- x x (a) (kit (2) t20011) od std at21124 bearing ar 101583- x x (a) (kit (2) t23568) us -0-254mm (0-01") (a) grinding guidelines : ctm8/ctm3274 21-14 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=106 1e13 engine (cd4039df/tf) liner/piston, code 4802,4803 chemise/piston, code 4802,4803 buechse/kolben, kode 4802,4803 camica motore/pistone, codice 4802,4803 camisa de cilindro/piston, codigo 4802,4803 cylinderfoder/kolv, koden 4802,4803 cd40213 -un-23may95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 re24458 piston-liner kit ar x (4802) re22678 piston-liner kit ar x (4803) 2 re66820 piston ring kit 1 x x packg (3) (sub for re15674) 3 - piston 1 x marked re19282, order re24458 (4802) - piston 1 x marked re19278, order re22678 (4803) 4 r131575 cylinder liner 1 x x a=196mm (7-71") (sub for r80724) 5 ar65507 o-ring kit 1 x x packg (3) 6 cd15466 shim ar x x tk 0-05mm (0-002") r65833 shim ar x x tk 0-10mm (0-004") genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-15 pn=107 1e14 engine (cd4039df/tf) without switch (oil) code 7699 sans interupteur (huile) code 7699 ohne schalter (oel) kode 7699 senza interruttore (olio) codice 7699 sin interruptor (aceite) codigo 7699 utan kontakt (olja) koden 7699 cd37313 -un-17feb95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 15h638 pipe plug 1 x x 1/8"-27nptf 21-16 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=108 1e15 engine (cd4039df/tf) oil pan, drain valve, code 1908 carter d’huile, robinet de vidange, code 1908 oelwanne, ablasshahn, kode 1908 coppa dell’olio, rubinetto di sarico, codice 1908 carter de aceite, grifo de vaciado, codigo 1908 oljetraag, avtappningskran, koden 1908 cd40004 -un-22aug95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 19h2676 cap screw 28 x x 3/8" x 1" 2 12h304 lock washer 28 x x 3/8" 3 t30726 strap 28 x x 4 re57482 oil pan 1 x x sheet metal,tole,blech,chapa,lameria,plaat 5 r119360 gasket 1 x x 6 r120247 gasket 1 x x copper, cuivre, kupfer, rame, cobre, koppar 7 r124128 adapter 1 x x m22 x 1-5mm-1/2"-14npt 8 15h602 elbow fitting 1 x x 1/2"-14npt x 1/2"-14npt 9 re59019 shut-off valve 1 x x 10 15h584 pipe plug 1 x x 1/2"-14npt genset power units南阳强鹿机滤RE57394找哪家,保定约翰迪尔柴油发动机大修包TRE532715价格,山南强鹿柴油机大修包OK6090供应商,台中约翰迪尔1204发动机大修包供应商,黔南约翰迪尔6059连杆瓦RE65908价格,淄博JohnDeereR502511气缸盖螺丝厂家供货,阳江约翰迪尔挖掘机大小瓦供货商,台南强鹿机油滤芯现货批发价,白银约翰迪尔6068柴油机水泵垫片供货商,榆林强鹿RE501578修理包厂家供货,牡丹江美国强鹿配件供应等信息诚信推荐,喀什强鹿4045油底壳垫片代理,武威强鹿发动机RE55343凸轮轴衬套哪家好,百色约翰迪尔连杆R51727哪里买,沧州强鹿柴油机R524469摇臂室盖垫片市场报价,锦州强鹿柴油发电机配件哪家买,甘南JohnDeere挺铜柱RE540586批发,蚌埠强鹿柴油发电机组全车线束批发,温州约翰迪尔挖掘机继电器代理商,黄冈美国约翰迪尔输油泵找哪家,庆阳约翰迪尔气门弹簧R518872公司,鞍山约翰迪尔强鹿垫圈批发商,桂林强鹿6081发动机主轴瓦一级代理,泰州约翰迪尔6081柴油机大修包公司, (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-17 pn=109 1e16 engine (cd4039df/tf) oil pump, code 5001,5002 pompe a huile, code 5001,5002 oelpumpe, kode 5001,5002 pompa dell’olio, codice 5001,5002 bomba de aceite, codigo 5001,5002 oljepump, koden 5001,5002 cd39105a -un-17aug95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 14h826 nut 1 x x 1/2"-13unc 2 t20298 gear 1 x x z=33, helicoidal tooth,denture helicoidale, schraegverzahnung,dentutara elicoidale, dentura helicoidal,skruvhju***rev 3 - oil pump 1 x marked r54615, ord re52020, (5001) - oil pump 1 x marked r54615, ord re52020, (5002) 4 r57059 cap screw 1 x x lgth=70mm (2-75"), up 5 12h304 lock washer 2 x x 3/8" 6 r59409 cap screw 2 x x lgth 102mm (3-89"), low 7 re64211 oil pump intake 1 x x a=114mm (4-56"), incl- instructions,anleitung,istruzioni, instrucciones,anvisningar 8 r61871 o-ring 1 x x 9 r74354 o-ring 1 x x 10 r115280 oil tube 1 x x 21-18 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=110 1e17 engine (cd4039df/tf) oil pump kit pompe a huile oelpumpe, teilesatz pompa dell’olio, serie pezzi bomba de aceite, juego oljepump, sats cd39128 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 re52020 kit ar x x 2 14h826 nut 1 x x 1/2"-13unc 3 - oil pump 1 x x marked r54615, ord re52020 4 r61871 o-ring 1 x x 5 r74354 o-ring 1 x x 6 r113752 oil tube na x x w/ color mark, marquage couleur, farbige markierung, marcatura colore, marca de color, faergidentifikation, 7 r115280 oil tube 1 x x appl 8 r97185 o-ring 1 x x 9 r75892 o-ring na x x genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-19 pn=111 1e18 engine (cd4039df/tf) filler neck/cover, code 1299 goulotte de remplissage/couvercle, code 1299 einfuellstutzen/deckel, kode 1299 bocchettone di riempimento/coperchio, codice 1299 boca de llenado/tapadera, codigo 1299 paafyllningshals/skyddskaapa, koden 1299 cd23133 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 r97352 gasket 1 x x 2 t23260 cover 1 x x 3 24h1304 washer 2 x x 13/32" x 23/32" x 0-120" 4 19h2284 cap screw 1 x x 3/8" x 7/8" 5 19h1726 cap screw 1 x x 3/8" x 2-1/4" 21-20 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=112 1e19 engine (cd4039df/tf) timing gear cover, code 4499 without tachometer drive&without magnetic pick-up couvercle de distribution, code 4499 sans entrainement de tachymetre et sans capteur magnetique steuergehaeuse, kode 4499 ohne drehzahlmesserantrieb und ohne magnetischer impu***eber coperchio distribuzione, codice 4499 senza comando tachimetro e senza sen***e magnetico contagiri tapa de la distribucion, codigo 4499 sin mando tacometro y sin captador magnetico tidhjulskapa, koden 4499 utan drivning varmaetre och utan magnetgivare cd37324 -un-17oct94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 19h3065 cap screw 6 x x 3/8" x 2" 2 24m7106 washer 14 x x 10 x 18 x 2-500 mm 3 19h1726 cap screw 1 x x 3/8" x 2-1/4" 4 19h2733 cap screw 4 x x 3/8" x 2-3/8" 5 19h1733 cap screw 2 x x 3/8" x 2-1/2" 6 19h2549 cap screw 1 x x 3/8" x 1-7/8" 7 - cover 1 x x aluminium,alluminio,aluminio,aluminium, marked r122417, order re51527 8 r97454 gasket 1 x x 9 re52977 drain plug 1 x x m42 x 2mm 10 l59904 o-ring 1 x x 38-700 x 2-800 mm 11 r91692 plug 1 x x 1"-16unc 12 a4827r washer 1 x x 13 24h1290 washer ar x x 21/64" x 3/4" x 0-035" 14 t27658 spring 1 x x 15 r83169 valve 1 x x genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-21 pn=113 1e20 engine (cd4039df/tf) timing gear cover kit couvercle de distribution, jeu de pieces steuergehaeuse, teilesatz coperchio distribuzione, serie pezzi tapa de la distribucion, jeugo tidhjulskapa, sats cd37327a -un-20jul95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 re51527 kit ar x x 2 19h3065 cap screw 5 x x 3/8" x 2" 3 24m7106 washer 13 x x 10 x 18 x 2-500 mm 4 19h2733 cap screw 4 x x 3/8" x 2-3/8" 5 19h3031 cap screw 2 x x 3/8" x 2-1/2" 6 19h2549 cap screw 1 x x 3/8" x 1-7/8" 7 19h1726 cap screw 2 x x 3/8" x 2-1/4" 8 19h2284 cap screw 1 x x 3/8" x 7/8" 9 ar67942 seal 1 x x 10 re52977 drain plug 1 x x m42 x 2mm 11 51m7049 o-ring 1 x x 38-600 x 2-900 mm 12 t23260 cover 1 x x 13 r97352 gasket 1 x x 14 r91692 plug 1 x x 15 a4827r washer 1 x x 1" x 1-1/4" x 0-064" 16 - cover 1 x x aluminium,alluminio,aluminio,aluminium, marked r114217, order re51527 17 r97454 gasket 1 x x 18 51m7044 o-ring 1 x x 0-681" x 0-087" 19 re38028 sen*** 1 x x 20 r65607 terminal 1 x x 21 - ground cable 1 x x lgth 150mm (5-90") mf r77499 22 r77491 terminal 1 x x - r77499 wire ar x x lgth 30-5m (100 ft) 21-22 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=114 1e21 engine (cd4039df/tf) closing for tachometer drive, code 4499 obturation pour entrainement de tachymetre, code 4499 abdeckung fuer drehzahlmesserantrieb, kode 4499 coperchio per comando tachimetro, codice 4499 tapa para mando tacometro, codigo 4499 lock foer drivning varvmaetare, koden 4499 cd36525 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 m1746t drain plug 1 x x 7/8"-14unf 2 h1058r washer 1 x x genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-23 pn=115 1e22 engine (cd4039df/tf) idle gear, code 3601,3602 pignon de distribution, code 3601,3602 steuerrad, kode 3601,3602 ingranaggio distribuzione, codice 3601,3602 engranaje de distribucion, codigo 3601,3602 tidhjul, koden 3601,3602 cd39157 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 t26327 screw 1 x x 2 r101227 thrust washer 1 x x 14-7mm x 58mm (0-578" x 2-28") front 3 ar91660 gear 1 x x (marked r70182) z = 55, helicoidal tooth, denture helicoidale, spiralverzahnung, dentatura elicoidale, dentura helicoidal, skruvhju***rev, up 4 t20034 bushing 1 x x 5 r109863 pin 1 x x o-d- 44-5mm (1-75") 6 r101225 thrust washer 1 x x 22mm x 60mm (0-866" x 2-36") rear 21-24 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=116 1e23 engine (cd4039df/tf) idle gear, code 3601,3602 pignon de distribution, code 3601,3602 steuerrad, kode 3601,3602 ingranaggio distribuzione, codice 3601,3602 engranaje de distribucion, codigo 3601,3602 tidhjul, koden 3601,3602 cd39158 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 14h865 nut 1 x x 1/2"-20unf 2 r101227 thrust washer 1 x x 14-7mm x 58mm (0-578" x 2-28") front 3 at24252 gear 1 x x (marked t26322) z = 45, helicoidal tooth, denture helicoidale, spiralverzahnung, dentatura elicoidale, dentura helicoidal, skruvhju***rev, low 4 t26321 bushing 1 x x 5 r109863 pin 1 x x o-d- 44-5mm (1-75") 6 r101225 thrust washer 1 x x 22mm x 60mm (0-866" x 2-36") rear 7 r100105 washer 1 x x 13-5mm x 30mm (0-531" x 1-18") rear 8 19h3011 cap screw 1 x x 1/2" x 2-1/8" genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-25 pn=117 1e24 engine (cd4039df/tf) universal front plate, code 3601,3602 plaque avant universelle, code 3601,3602 universelle front plate, kode 3601,3602 piastra anteriore universale, codice 3601,3602 placa delantero universal, codigo 3601,3602 universalfrontplata, koden 3601,3602 cd35803a -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 r131794 engine cylinder head gasket 1 x x (sub for r90648, this application) 2 12h324 washer 5 x x 3/8" 3 t20166 screw 5 x x 4 r79863 plate 1 x x (also order (8) at21191&(2) at22919) 5 r79854 washer ar x x o-d- x i-d- 50mm x 46mm (1-96" x 1-81") 6 at21191 set screw 8 x x 5/16" x 0-380" 7 at22919 set screw 2 x x 3/8" x 0-380" 8 t23442 stud 3 x x lgth 36-6mm (1-44") x 5/16"-24ns x 5/16"-18unc 9 a22698 nut 3 x x 5/16"-18unc 21-26 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=118 engine (cd4039df/tf) memoranda genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-27 pn=119 1f1 engine (cd4039df/tf) water pump, 290mm (11-4") code 2007 pompe a eau, 290mm (11-4") code 2007 wasserpumpe, 290mm (11-4") kode 2007 pompa dell’acqua, 290mm (11-4") codice 2007 bomba de agua, 290mm (11-4") codigo 2007 vattenpump, 290mm (11-4") koden 2007 cd40001 -un-22aug95 this parts listing is continued 21-28 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=120 1f2 engine (cd4039df/tf) 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 re58910 water pump 1 x (marked r67188) 2 t23628 pulley 1 x 11/16" x od 126mm (4-96") 3 19h3219 cap screw 2 x 3/8" x 1-3/8" 4 15h584 pipe plug 1 x 1/2"-14nptf 5 t19651 hose fitting 1 x 1/4"-18nptf 6 r97455 gasket 1 x 7 r102901 cover 1 x tk 6mm (0-231") 8 t20243 gasket 1 x 9 12h304 lock washer 4 x 3/8" 10 19h3065 cap screw 1 x 3/8" x 2" 11 19h1912 cap screw 1 x 3/8" x 3-1/2" 12 19h3413 screw 1 x 3/8" x 3-1/4" 13 14h1076 nut ar x 3/8"-16unc 14 re62658 kit ar x genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-29 pn=121 1f3 engine (cd4039df/tf) water pump, 290mm (11-4") code 2026 pompe a eau, 290mm (11-4") code 2026 wasserpumpe, 290mm (11-4") kode 2026 pompa dell’acqua, 290mm (11-4") codice 2026 bomba de agua, 290mm (11-4") codigo 2026 vattenpump, 290mm (11-4") koden 2026 cda37207 -un-17feb95 this parts listing is continued 21-30 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=122 1f4 engine (cd4039df/tf) 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 ar97708 water pump 1 x (marked r73604) 2 t23628 pulley 1 x 11/16" x od 126mm (4-96") 3 r48993 tube 2 x id 16mm (0-62") 4 19h3219 cap screw 2 x 3/8" x 1-3/8" 5 15h584 pipe plug 1 x 1/2"-14nptf 6 t19651 hose fitting 1 x 1/4"-18nptf 7 r97455 gasket 1 x 8 r102901 cover 1 x tk 6mm (0-231") 9 t20243 gasket 1 x 10 12h304 lock washer 4 x 3/8" 11 19h3065 cap screw 1 x 3/8" x 2" 12 19h1912 cap screw 1 x 3/8" x 3-1/2" 13 19h3413 screw 1 x 3/8" x 3-1/4" 14 14h1076 nut ar x 3/8"-16unc 15 re62658 kit ar x genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-31 pn=123 1f5 engine (cd4039df/tf) oil cooler (6 plates) code 5904 refroidisseur d’huile (6 plaques) code 5904 oelkuehler (6 platten) kode 5904 radiatore dell’olio (6 piastra) codici 5904 refrigerador de aceite (6 placa) codigo 5904 oljekylare (6 hyvel) koden 5904 cd37218a -un-17aug95 this parts listing is continued 21-32 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=124 1f6 engine (cd4039df/tf) 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 ar21837 clamp 8 x 2 - hose 1 x lgth 60mm, (make from r83063) 3 r99259 hose 1 x 4 r99258 line 1 x id 16mm (0-62") 5 r99254 line 2 x id 16mm (0-62") 6 r99252 hose 1 -185223 x 13/16"-16un x lgth 62mm (2-44") r125507 threaded nipple 1 185224- 13/16"-16un x lgth 54mm (2-13") 7 re38077 oil cooler 1 -185223 x behr, (order re61767&r125507) re61767 oil cooler 1 185224- x behr 8 r70956 washer 1 -185223 x id x od x tk 68-5mm x 76-2mm x 4-8mm r125508 packing 1 185224- x id x od x tk 67mm x 74-4mm x 3-6mm 9 19h1726 cap screw 1 x 3/8" x 2-1/4", id x od x tk 68-6mm x 76-2mm x 4-8mm (2-7" x 3" x 0-18") 10 r53524 clamp 1 x 11 r99257 washer 1 x tk 5mm 12 24h1304 washer 1 x 13/32" x 23/32" x 0-120" - r83063 hose 1 x id x lgth 16mm x 2370mm (0-62" x 93-30") genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-33 pn=125 1f7 engine (cd4039df/tf) thermostat cover, code 2109,2112 couvercle de thermostat, code 2109,2112 thermostatdeckel, kode 2109,2112 coperchio termostato, codice 2109,2112 tapareda termostato, codigo 2109,2112 skyddskaapa termostat, koden 2109,2112 cd12523 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 19h1800 cap screw 2 x x 3/8" x 1-1/2" 2 24h1020 washer 2 x x 13/32" x 23/32" x 0-120" 3 r97876 cover 1 x x synthetic material, materiau composite, kunststoffmaterial, materia sintetica, materiales sinteticos, syntetisk material 4 r97877 o-ring 1 x x 21-34 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=126 1f8 engine (cd4039df/tf) thermostat, code 2204,2208 thermostat, code 2204,2208 thermostat, kode 2204,2208 termostato, codice 2204,2208 termostato, codigo 2204,2208 termostat, koden 2204,2208 cd37214 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 re501052 thermostat 1 x x 82°c (181°f) (sub for re64354) genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-35 pn=127 1f9 engine (cd4039df/tf) thermostat housing, code 3909 boitier de thermostat, code 3909 thermostatgehaeuse, kode 3909 sede termostato, codice 3909 caja del termostato, codigo 3909 termostathus, koden 3909 cdb37216 -un-20jul95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 19h3031 cap screw 2 x x 3/8" x 2-1/2" 2 r105806 housing 1 x x a = 48mm (1-89") 3 15h624 pipe plug 1 x x 1/2"-14npt 4 t19651 hose fitting 1 x x 1/4"-18nptf 5 r54641 gasket 1 x x 6 ar21837 clamp 2 x x 7 t20277 hose 1 x x 21-36 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=128 1f10 engine (cd4039df/tf) pulley, code 1317 poulie, code 1317 riemenscheibe, kode 1317 puleggia, codice 1317 polea, codigo 1317 remskiva, koden 1317 cd40204 -un-23may95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 19h2473 cap screw 1 x x 1/2" x 1-3/4" 2 r109086 spacer 1 x x tk x od = 10mm x 44mm (0-393" x 1-732") 3 r119220 sheave 1 x x 4 r81989 sleeve 1 x x 5 h35244 ring 1 x x 6 26h27 shaft key 1 x x 7 - cap screw ar x x 7/16"-14unc genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-37 pn=129 1f11 engine (cd4039df/tf) flywheel, code 1505 volant, code 1505 schwungrad, kode 1505 volano, codice 1505 volante, codigo 1505 svaenghjul, koden 1505 cd36402 -un-01jan94 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 19h2993 cap screw 4 x x hs, sae 8, 1/2" x 1-1/2" 2 re58568 flywheel 1 x x (marked r120765) (sub for re56417) 3 r28811 ring gear 1 x x z=129, m 8/10, id 385mm (15-15") 21-38 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=130 1f12 engine (cd4039df/tf) flywheel housing, sae 3, 3 holes mouting flange, r-h- code 1421 carter de volant, sae 3, bride de fixation a 3 trous a droite, code 1421 schwungradgehaeuse, sae 3, befestigungsflansch mit 3 bohrungen, rechts, kode 1421 carcassavolano, sae 3, flangia di montaggio a 3 fori, a destra, codice 1421 carcasavolante, sae 3, brida de sujecion a 3 agjeros, a la derecha, codigo 1421 hus svaeghjul, sae 3, monterings flens med 3 haal, hoeger sida, koden 1421 cd35628a -un-22aug95 4 4 0 0 3 3 engine 9 9 key part no- part name qty serial no- d t remarks 1 r120586 housing 1 x x 2 r21630 pipe plug 1 x x 1/8"-27npt (7699) 3 15h624 pipe plug 1 x x 1/2"-14npt 4 19h3219 cap screw 8 x x 3/8" x 1-3/8" 5 19h1923 cap screw 4 x x 5/8" x 5-1/2" 6 r121768 document 1 x x (sub for r83555) 7 r97351 gasket 1 x x 8 t22867 drain plug na x x 3/4"-16unf genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) 21-39 pn=131 1f15 engine (cd4045tf) valve cover, code 1104 cache-culbuteurs, code 1104 ventildeckel, kode 1104 coperchio valvole, codige 1104 tapa de valvula, codigo 1104 ventilkaapa, koden 1104 cd35608b -un-21feb96 4 0 4 engine 5 key part no- part name qty serial no- t remarks 1 re44205 valve cover 1 x synthetic material, materiau composite, kunststoffmaterial, materia sintetica, materiales sinteticos, syntetisk material 2 r106796 o-ring 1 x 3 re42762 filler cap 1 x with gasket, avec joint, mit dichtung, con guarnizione, con junta, med packning 4 re32140 screw, with washer 8 x 22-2 genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (20-jan-98) pn=132 1f16 engine (cd4045tf) breather, code 2902 reniflard, code 2902 entluefter, kode 2902 sfiatatoio, codice 2902 respiradero, codigo 2902 ventilator, koden 2902 cda36501 -un-02dec94 4 0 4 engine 5 key part no- part name qty serial no- t remarks 1 r56463 o-ring 1 x 2 r92154 elbow fitting 1 x 3 at18904 clamp 1 x 4 r99793 hose 1 x lgth 889mm (35") (order r122401) r122401 hose 1 x lgth1040mm (40-94") 5 19h2038 cap screw 1 x 3/8" x 1/2" 6 24m7096 washer 1 x 10-500 x 18 x 1-600 mm 7 t35699 clamp 1 x genset power units (cd3029df,cd4039df/tf,cd4045tf,cd6059tf,cd6068tf) pc2450 (30-nov-95) 22-3 pn=133 1f17 engine (cd4045tf) rocker arm/rocker arm shaft/tappet/push rod, code 4902 culbuteur/arbre de culbuteurs/poussoir de soupape/tige de culbuteur, code 4902