配件详情

麦克福斯约翰迪尔发动机零配件

|

|

|

约翰迪尔 4045T 4.5T 活塞(米) RE59277/RE505100

|

|

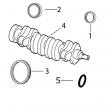

||||||||||||||||||||||||||||

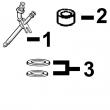

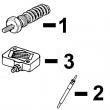

(1)这些标记号RE59277,RE505100要求使用Ring Set TRE66271。约翰迪尔已经停产

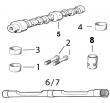

(2)使用机器拆分连杆使用TR114083,并使用TR501124与破裂的分裂连接杆。

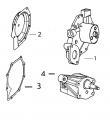

(3)与Oil Pan code 1901,1902& 1903年,钢制油锅。

(4)使用Oil Pan code 1904& 1905年,为铝油盘。

(5)用法兰头帽螺钉替换所有R78558带帽螺钉TR85363。

(6)(m)R135439,R132324,R134213。

(7)线路连接都是线程化的。

(8)  在曲轴加工过程中必须保持适当的轴承轴颈半径,以确保正确的操作。

(9)1件组合式密封和穿套;替换TRE59810,RE538097。

(10)检查应用程序是否正确使用。

(11)与Stanadyne DE10注射泵一起使用。

(12)锥形鼻子。

(13)直鼻。

(14)线路连接是一个 软管倒钩&一个线程。

(15)线路连接是两个软管倒钩。

(16)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

RE507980、RE531703、RE24619、RE187966、RE205726、RE507264、RE504836、RE509036、RE533910、RE532952、RE530107、RE508971、RE523502、RE518520、RE68345、RE53307、RE62240、RE533095、RE502513、RE38009、R30402、RE521538、RE521540、RE62240、P524837、RE60021、RE507236、RE59588、RE549153、RE530870、SE501610、SE501609、RE70960/

美国强鹿JOHN DEERE柴油发电机配件及发动机配件:

CD3029DF128、CD4039DF008、CD4045TF258、PE4045、CD6068TF158、CD6068TF258、CD6068HF158、CD6068HF258、CD6081HF001A、4045TFM75、CD6081HF001B、CD6125HF070A、CD6125HF070B、RG6125、6135H458。4045DFM70, 4045TFM75, 6068TFM75, 6068TFM76、4039DFM RE522528、RE519774、RE532628、RE518176、RE507980、RE518503、RE522515、RE504836、RE509031re507763 oil line 1 10 24m7239 washer 4 11 r127941 cap screw 4 12 elbow fitting 1 (code 5901) 13 exhaust manifold 1 (code 2802) (a) remanufactured echange standard generaueberholt rigatto refabricado renoverad powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 6500-6509 pn=525 p r o o f p r o o f turbocharger, oil lines&pipe 6516 6516 6516 6516 6516 6516 rgp7891 -un-15aug01 engine key part no. part name qty serial no. remarks 1 a4925r fitting 1 2 re508021 turbocharger 1 (a) (marked re506838) (borg warner) 3 r49697 gasket 1 4 r105346 gasket 1 5 re65198 oil line 1 6 r72328 o-ring 1 7 r41285 adapter 1 8 cc22170 cap screw 2 9 re503761 line 1 10 24m7239 washer 4 11 r127941 cap screw 4 12 elbow fitting 1 (code 5901) 13 exhaust manifold 1 (code 2802) (a) remanufactured echange standard generaueberholt rigatto refabricado renoverad 6500-6510 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=526 p r o o f p r o o f air conditioning compres*** sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8063 -un-15aug01 7401 - 7402 - 7405 - 7406 - 7407 - 7498 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7400-a01 pn=527 p r o o f p r o o f air conditioning compres*** sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 7401 - 7402 - 7405 - 7406 - 7407 - 7498 - 7400-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=528 p r o o f p r o o f air conditioning compres*** 7401 7401 7401 7401 7401 7401 rgp7173 -un-13dec00 engine key part no. part name qty serial no. remarks 1 14m7296 flange nut 2 m10 2 r128858 bracket 1 3 r128802 bracket 1 4 19m7898 screw 2 m10 x 130 r72853 clamp 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 7400-7401 pn=529 p r o o f p r o o f air conditioning compres*** 7402 7402 7402 7402 7402 7402 rgp7174 -un-13dec00 this parts listing is continued 7400-7402 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=530 p r o o f p r o o f air conditioning compres*** engine key part no. part name qty serial no. remarks 1 14m7296 flange nut 2 m10 2 r128858 bracket 1 3 r128802 bracket 1 4 19m7898 screw 2 m10 x 130 5 re46609 compres*** 1 (12v) 6 19m7913 screw 3 m8 x 90 7 14m7298 flange nut 3 r72853 clamp 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7400-7403 pn=531 p r o o f p r o o f air conditioning compres*** 7405 7405 7405 7405 7405 7405 rgp7175 -un-13dec00 this parts listing is continued 7400-7404 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=532 p r o o f p r o o f air conditioning compres*** engine key part no. part name qty serial no. remarks 1 14m7296 flange nut 2 m10 2 r500063 bracket 1 3 r128802 bracket 1 4 19m7898 screw 2 m10 x 130 5 re68372 compres*** 1 6 19m7970 screw 3 m8 x 100 7 14m7298 flange nut 3 m8 8 24h1306 washer 2 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7400-7405 pn=533 p r o o f p r o o f air conditioning compres*** 7406 7406 7406 7406 7406 7406 rgp7176 -un-13dec00 engine key part no. part name qty serial no. remarks 1 14m7296 flange nut 2 m10 2 r500063 bracket 1 3 r128802 bracket 1 4 19m7898 screw 2 m10 x 130 5 24h1306 washer 2 7400-7406 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=534 p r o o f p r o o f air conditioning compres*** memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7400-7407 pn=535 p r o o f p r o o f air conditioning compres*** 7407 7407 7407 7407 7407 7407 rgp7174 -un-13dec00 this parts listing is continued 7400-7408 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=536 p r o o f p r o o f air conditioning compres*** engine key part no. part name qty serial no. remarks 1 14m7296 flange nut 2 m10 2 r128858 bracket 1 3 r128802 bracket 1 4 19m7898 screw 2 m10 x 130 5 at172975 compres*** 1 (24v) 6 19m7913 screw 3 m8 x 90 7 14m7298 flange nut 3 r72853 clamp 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7400-7409 pn=537 p r o o f p r o o f air conditioning compres*** 7498 7498 7498 7498 7498 7498 rgp7895 -un-15aug01 engine key part no. part name qty serial no. remarks 1 19m8292 screw 1 m10 x 50 2 r502079 sleeve 1 3 re506518 idler 1 4 r503848 spacer 1 5 r504731 bracket 1 6 19m7836 screw 2 (code 7700) 7400-7410 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=538 p r o o f p r o o f air conditioning compres*** memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7400-7411 pn=539 p r o o f p r o o f air conditioning compres*** memoranda memoranda memoranda memoranda memoranda memoranda 7400-7412 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=540 p r o o f p r o o f sen***, oil pressure sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8064 -un-15aug01 7601 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7600-a01 pn=541 p r o o f p r o o f sen***, oil pressure sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 7601 - 7600-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=542 p r o o f p r o o f sen***, oil pressure 7601 7601 7601 7601 7601 7601 rgp6808 -un-18jul00 engine key part no. part name qty serial no. remarks 1 re56009 engine oil press. sen*** 1 2 15h639 pipe bushing 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 7600-7601 pn=543 p r o o f p r o o f sen***, oil pressure memoranda memoranda memoranda memoranda memoranda memoranda 7600-7602 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=544 p r o o f p r o o f front plate&timing gear cover sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8065 -un-15aug01 7701 - 7703 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7700-a01 pn=545 p r o o f p r o o f front plate&timing gear cover sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 7701 - 7703 - 7700-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=546 p r o o f p r o o f front plate&timing gear cover memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 7700-7701 pn=547 p r o o f p r o o f front plate&timing gear cover 7701 7701 7701 7701 7701 7701 rgp7177 -un-13dec00 this parts listing is continued 7700-7702 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=548 p r o o f p r o o f front plate&timing gear cover engine key part no. part name qty serial no. remarks 1 r500212 gasket 1 n102039 cap 4 2 re501740 plate 1 (marked r500117) n102039 cap 1 3 r502026 gasket 1 4 19m8551 screw 5 m10 x 25 5 r26333 washer 1 (opt 5298) 6 19m7488 cap screw 1 m16 x 40, (opt 5298) 7 19m7867 screw 3 m8 x 25 8 r119157 cover 1 9 19m8738 cap screw 3 m10 x 45 10 re53911 gear 1 (b) 11 r501309 plate 1 12 19m7836 screw 2 m10 x 110 13 19m7786 screw 2 m10 x 30, (opt 2300) 14 19m7812 screw 6 m10 x 100, (opt 2300) 15 14m7296 flange nut 1 m10, (opt 2300) 16 r129809 cover 1 (opt 2300) 17 r502441 v-ring seal 1 18 19m7836 screw 2 m10 x 110 19 19m8528 screw 7 m10 x 55 19m8114 screw 1 m10 x 70 20 r119159 bolt 1 21 r502470 cover 1 22 t70176 ring 1 (opt 5200) 23 r126926 cover 1 (a) (opt 7879) 24 r136091 cap screw 2 (opt 5200) 25 r43696 washer 3 (a) camshaft arbre a cames nockenwelle albero a camme eje de levas kamazel/ventiler (b) idler tendeur zwischenzahnrad ingranaggio intermedio rueda ten***a mellandrev powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 7700-7703 pn=549 p r o o f p r o o f front plate&timing gear cover 7703 7703 7703 7703 7703 7703 rgp7183 -un-13dec00 this parts listing is continued 7700-7704 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=550 p r o o f p r o o f front plate&timing gear cover engine key part no. part name qty serial no. remarks 1 r500212 gasket 1 n102039 cap 4 2 re501741 plate 1 (marked r128730) 3 r502026 v-ring seal 1 4 19m8551 screw 5 m10 x 25 5 r26333 washer 1 (opt 5200) 6 19m7488 cap screw 1 m16 x 40, (5200) 7 r43696 washer 3 8 r119157 cover 1 9 19m8738 cap screw 3 10 re53911 gear 3 (b) 11 r501309 plate 1 12 19m7867 screw 1 13 19m7836 screw 2 m10 x 110 14 19m7786 screw 2 m10 x 30, (opt 2300) 15 19m7812 screw 6 (opt 2300) 16 14m7296 flange nut 1 m10, (opt 2300) 17 r129809 cover 1 (a) (opt 2300) 18 r502441 v-ring seal 1 19 r131660 drain plug 1 20 t74492 o-ring 1 21 r502530 cover 1 22 19m8528 screw 7 m10 x 55 23 19m7836 screw 2 m10 x 110 24 19m8114 screw 1 m10 x 70 25 r120801 dipstick tube 1 26 re500250 filler cap 1 27 r119159 bolt 1 (a) camshaft arbre a cames nockenwelle albero a camme eje de levas kamaxel/ventiler (b) idler tendeur zwischenzahnrad ingranaggio intermedio rueda ten***a mellandrev powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 7700-7705 pn=551 p r o o f p r o o f front plate&timing gear cover memoranda memoranda memoranda memoranda memoranda memoranda 7700-7706 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=552 p r o o f p r o o f front plate&timing gear cover engine key part no. part name qty serial no. remarks 1 r500212 gasket 1 n102039 cap 4 2 re501741 plate 1 (marked r128730) 3 r502026 v-ring seal 1 4 19m8551 screw 5 m10 x 25 5 r26333 washer 1 (opt 5200) 6 19m7488 cap screw 1 m16 x 40, (5200) 7 r43696 washer 3 8 r119157 cover 1 9 19m8738 cap screw 3 10 re53911 gear 3 (b) 11 r501309 plate 1 12 19m7867 screw 1 13 19m7836 screw 2 m10 x 110 14 19m7786 screw 2 m10 x 30, (opt 2300) 15 19m7812 screw 6 (opt 2300) 16 14m7296 flange nut 1 m10, (opt 2300) 17 r129809 cover 1 (a) (opt 2300) 18 r502441 v-ring seal 1 19 r131660 drain plug 1 20 t74492 o-ring 1 21 r502530 cover 1 22 19m8528 screw 7 m10 x 55 23 19m7836 screw 2 m10 x 110 24 19m8114 screw 1 m10 x 70 25 r120801 dipstick tube 1 26 re500250 filler cap 1 27 r119159 bolt 1 (a) camshaft arbre a cames nockenwelle albero a camme eje de levas kamaxel/ventiler (b) idler tendeur zwischenzahnrad ingranaggio intermedio rueda ten***a mellandrev powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 7700-7713 pn=553 p r o o f p r o o f front plate&timing gear cover memoranda memoranda memoranda memoranda memoranda memoranda 7700-7714 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=554 p r o o f p r o o f air compres*** sectional index index de section gruppenindex indico della sezione indice de seccion gruppsforteckning rgp8066 -un-15aug01 7801 - 7802 - 7803 - 7804 - 7805 - powertech 12.5l 6125hf070 engine (waterloo) 达州强鹿约翰迪尔TR97492排气门供货商,百色强鹿6068柴油机气缸垫信息,怒江JohnDeere连杆瓦R116081哪家好,通辽美国强鹿配件优质批发价格,烟台美国JohnDeere缸套阻水圈AR72351哪家好,泰安johndeere约翰迪尔强鹿柴油发动机机滤RE530107批发商,黄冈johndeere约翰迪尔强鹿柴油机气门市场报价,南平约翰迪尔E210/E210LC挖掘机发动机配件厂家批发,天水强鹿柴油机四配套多少钱,阜新约翰迪尔连杆瓦R116081价格,福州强鹿柴油机充电机RE34888一级代理,平凉强鹿柴油机活塞环RE507852市场报价,绵阳强鹿柴油滤RE62418报价哪家好,汕尾约翰迪尔张紧轮RE518097的价格,雅安约翰迪尔强鹿3029燃油输送泵诚信推荐,海东约翰迪尔6081发动机连杆哪家好,酒泉约翰迪尔4045TF150发动机配件价格,宁波约翰迪尔强鹿气门室盖垫片供货商,吉安JohnDeere空气加热器el502668多少钱,洛阳强鹿6081柴油发动机凸轮轴塞多少钱,台中强鹿柴油发电机组涡轮增压器厂家供应,西双版纳约翰迪尔6081柴油机缸套市场报价,玉林强鹿柴油机3029电子燃油泵信息,伊春强鹿滤芯滤清器RE59574找哪家,德州johndeere约翰迪尔强鹿柴油机水泵垫片厂家批发,乌海约翰迪尔止推轴承瓦RE529320批发商,惠州约翰迪尔强鹿4045柴油机水泵盖信息,阿克苏约翰迪尔强鹿柴油发动机电子燃油泵信息,佳木斯强鹿6090柴油发动机后油封诚信推荐,景德镇约翰迪尔6090柴油机加大主轴瓦公司,广安johndeere约翰迪尔强鹿柴油发动机柴滤RE533910哪家好,信阳约翰迪尔RE502203柴油滤芯厂家批发,自贡johndeere约翰迪尔强鹿柴油机风扇找哪家,广元强鹿柴油机进排气门座圈信息,大兴安岭johndeere约翰迪尔强鹿柴油发动机增压器RE509435代理商,楚雄约翰迪尔RE560752机油冷却器一级代理,(esn 030000- ) pc2875 (09-jan-02) 7800-a01 pn=555 p r o o f p r o o f air compres*** sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 7801 - 7802 - 7803 - 7804 - 7805 - 7800-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=556 p r o o f p r o o f air compres*** memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 7800-7801 pn=557 p r o o f p r o o f air compres*** 7801 7801 7801 7801 7801 7801 rgp7179 -un-13dec00 this parts listing is continued 7800-7802 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=558 p r o o f p r o o f air compres*** engine key part no. part name qty serial no. remarks 1 r132808 tube 1 2 ty22467 clamp 6 3 r129607 hose 1 4 r75562 adapter 1 5 r26375 o-ring 1 6 t20900 hose 1 7 m45937 elbow fitting 1 8 t70176 ring 1 9 r136091 cap screw 3 10 re65093 compres*** 1 (holset - 13.2 cfm) r116530 gear 1 r133567 cap screw 1 m557t washer 1 11 r26375 o-ring 1 12 r75562 adapter 1 13 19m7785 screw 1 14 r113490 hose 1 15 r59873 hose fitting 1 16 r502044 bracket 1 17 r500185 support 1 18 19m7783 screw 1 m10 x 16 19 r129608 hose 1 20 r39503 fitting 1 21 t37796 hose fitting 1 22 ar21839 clamp 2 23 r500574 suction hose 1 24 19m7804 screw 2 m10 x 40 25 28h1522 spacer 2 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 7800-7803 pn=559 p r o o f p r o o f air compres*** 7802 7802 7802 7802 7802 7802 rgp7179 -un-13dec00 this parts listing is continued 7800-7804 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=560 p r o o f p r o o f air compres*** engine key part no. part name qty serial no. remarks 1 r132808 tube 1 2 ty22467 clamp 6 3 r129607 hose 1 4 r75562 adapter 1 5 r26375 o-ring 1 6 t20900 hose 1 7 m45937 elbow fitting 1 8 t70176 ring 1 9 r136091 cap screw 3 10 re69650 compres*** 1 (holset - 15.0 cfm) r116530 gear 1 r133567 cap screw 1 m557t washer 1 11 r26375 o-ring 1 12 r75562 adapter 1 13 19m7785 screw 1 14 r113490 hose 1 15 r59873 hose fitting 1 16 r502044 bracket 1 17 r500185 support 1 18 19m7783 screw 1 m10 x 16 19 r129608 hose 1 20 r39503 fitting 1 21 t37796 hose fitting 1 22 ar21839 clamp 2 23 r500574 suction hose 1 24 19m7804 screw 2 m10 x 40 25 28h1522 spacer 2 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 7800-7805 pn=561 p r o o f p r o o f air compres*** 7803 7803 7803 7803 7803 7803 rgp7180 -un-13dec00 this parts listing is continued 7800-7806 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=562 p r o o f p r o o f air compres*** engine key part no. part name qty serial no. remarks 1 t37796 hose fitting 1 2 ar21839 clamp 2 3 r500574 suction hose 1 4 r130625 hose 1 5 r42312 hose fitting 2 6 t20900 hose 1 7 m45937 elbow fitting 1 8 t70176 ring 1 9 r136091 cap screw 3 10 re500297 compres*** 1 (holset - 34 cfm) r116530 gear 1 r133567 cap screw 1 m557t washer 1 11 r502046 bracket 1 12 19m7804 screw 2 13 ty22467 clamp 6 14 r53811 hose 1 15 19m7785 screw 1 16 t27077 hose fitting 1 17 28h1522 spacer 2 18 r39503 fitting 1 19 r129608 hose 1 20 r500216 tube 1 21 19m7783 screw 1 m10 x 16 22 r500185 support 1 re46684 plug 1 r500612 adapter 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 7800-7807 pn=563 p r o o f p r o o f air compres*** 7804 7804 7804 7804 7804 7804 rgp7181 -un-13dec00 this parts listing is continued 7800-7808 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=564 p r o o f p r o o f air compres*** engine key part no. part name qty serial no. remarks 1 t37796 hose fitting 1 2 ar21839 clamp 2 3 r500574 suction hose 1 4 r108661 hose 1 5 r75562 adapter 2 r26375 o-ring 2 6 t20900 hose 1 7 m45937 elbow fitting 1 8 t70176 ring 1 9 14m7299 flange nut 3 10 re501186 compres*** 1 (holset - 13.2 cfm) 11 r502045 bracket 1 12 19m7804 screw 2 13 ty22467 clamp 6 14 r129607 hose 1 15 19m7785 screw 1 16 42m7071 stud 1 17 28h1522 spacer 2 18 r39503 fitting 1 19 r129608 hose 1 20 r132808 tube 1 21 19m7783 screw 1 m10 x 16 22 r500185 support 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 7800-7809 pn=565 p r o o f p r o o f air compres*** 7805 7805 7805 7805 7805 7805 rgp7181 -un-13dec00 this parts listing is continued 7800-7810 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=566 p r o o f p r o o f air compres*** engine key part no. part name qty serial no. remarks 1 t37796 hose fitting 1 2 ar21839 clamp 2 3 r500574 suction hose 1 4 r108661 hose 1 5 r75562 adapter 2 r26375 o-ring 2 6 t20900 hose 1 7 m45937 elbow fitting 1 8 t70176 ring 1 9 14m7299 flange nut 3 10 re501187 compres*** 1 (holset - 15.0 cfm) 11 r502045 bracket 1 12 19m7804 screw 2 13 ty22467 clamp 6 14 r129607 hose 1 15 19m7785 screw 1 16 42m7071 stud 1 17 28h1522 spacer 2 18 r39503 fitting 1 19 r129608 hose 1 20 r132808 tube 1 21 19m7783 screw 1 m10 x 16 22 r500185 support 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 7800-7811 pn=567 p r o o f p r o o f air compres*** memoranda memoranda memoranda memoranda memoranda memoranda 7800-7812 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=568 p r o o f p r o o f acces***y kits sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8421 -un-20dec01 9206 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9200-a01 pn=569 p r o o f p r o o f acces***y kits sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 9206 - 9200-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=570 p r o o f p r o o f acces***y kits 9206 9206 9206 9206 9206 9206 rgp8420 -un-20dec01 engine key part no. part name qty serial no. remarks 1 r132586 bracket 1 2 19m7844 screw 4 m16 x 45 3 r128835 support 1 19m7812 screw 1 m10 x 100 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9200-9201 pn=571 p r o o f p r o o f acces***y kits memoranda memoranda memoranda memoranda memoranda memoranda 9200-9202 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=572 p r o o f p r o o f engine installation kit sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp7237 -un-31jan01 9608 - 9609 - 9610 - 9611 - 9612 - 9613 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-a01 pn=573 p r o o f p r o o f engine installation kit sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 9608 - 9609 - 9610 - 9611 - 9612 - 9613 - 9600-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=574 p r o o f p r o o f engine installation kit memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-9601 pn=575 p r o o f p r o o f engine installation kit 9608 9608 9608 9608 9608 9608 rgp6599 -un-06jul00 this parts listing is continued 9600-9602 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=576 p r o o f p r o o f engine installation kit engine key part no. part name qty serial no. remarks 1 re504618 wiring harness 1 (12v) 2 ah130222 clamp 2 3 19m7788 screw 2 m12 x 25 4 14m7296 flange nut 1 m10 5 re500805 wiring harness 1 6 re500927 wire 1 7 r44302 tie band 1 8 engine controller na 9 r72659 clamp 1 10 r500488 isolator 3 11 r72659 clamp 3 19m7783 screw 3 12 re500588 bracket 1 13 19m7786 screw 3 14 19m8483 cap screw 4 15 24m7296 washer 3 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-9603 pn=577 p r o o f p r o o f engine installation kit 9609 9609 9609 9609 9609 9609 rgp6599 -un-06jul00 this parts listing is continued 9600-9604 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=578 p r o o f p r o o f engine installation kit engine key part no. part name qty serial no. remarks 1 re504618 wiring harness 1 (24v) 2 ah130222 clamp 2 3 19m7788 screw 2 m12 x 25 4 14m7296 flange nut 1 m10 5 re500805 wiring harness 1 6 re500927 wire 1 7 r44302 tie band 1 8 engine controller na 9 r72659 clamp 1 10 r500488 isolator 3 11 r72659 clamp 3 19m7783 screw 3 m10 x 16 12 r500588 adapter 1 13 19m7786 screw 3 14 19m8483 cap screw 4 15 24m7296 washer 3 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-9605 pn=579 p r o o f p r o o f engine installation kit 9610 9610 9610 9610 9610 9610 rgp6599 -un-06jul00 this parts listing is continued 9600-9606 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=580 p r o o f p r o o f engine installation kit engine key part no. part name qty serial no. remarks 1 re504666 wiring harness 1 (10 ft) (12v) 2 ah130222 clamp 2 3 19m7788 screw 2 m12 x 25 4 14m7296 flange nut 1 m10 5 re500805 wiring harness 1 6 re500927 wire 1 7 r44302 tie band 1 8 engine controller na 9 r72659 clamp 1 10 r500488 isolator 3 11 r72659 clamp 3 19m7783 screw 3 m10 x 16 12 bracket na 13 screw na 14 screw na 15 washer na powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-9607 pn=581 p r o o f p r o o f engine installation kit 9611 9611 9611 9611 9611 9611 rgp6599 -un-06jul00 this parts listing is continued 9600-9608 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=582 p r o o f p r o o f engine installation kit engine key part no. part name qty serial no. remarks 1 re504666 wiring harness 1 (10 ft) (24v) 2 ah130222 clamp 2 3 19m7788 screw 2 m12 x 25 4 14m7296 flange nut 1 m10 5 re500805 wiring harness 1 6 re500927 wire 1 7 r44302 tie band 1 8 engine controller na 9 r72659 clamp 1 10 r500488 isolator 3 11 r72659 clamp 3 19m7783 screw 3 m10 x 16 12 bracket na 13 screw na 14 screw na 15 washer na powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-9609 pn=583 p r o o f p r o o f engine installation kit 9612 9612 9612 9612 9612 9612 rgp6599 -un-06jul00 this parts listing is continued 9600-9610 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=584 p r o o f p r o o f engine installation kit engine key part no. part name qty serial no. remarks 1 re504667 wiring harness 1 (20 ft) (12v) 2 ah130222 clamp 2 3 19m7788 screw 2 m12 x 25 4 14m7296 flange nut 1 m10 5 re500805 wiring harness 1 6 re500927 wire 1 7 r44302 tie band 1 8 engine controller na 9 r72659 clamp 1 10 r500488 isolator 3 11 r72659 clamp 3 19m7783 screw 3 m10 x 16 12 bracket na 13 screw na 14 screw na 15 washer na powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9600-9611 pn=585 p r o o f p r o o f engine installation kit 9613 9613 9613 9613 9613 9613 rgp6599 -un-06jul00 this parts listing is continued 9600-9612 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=586 p r o o f p r o o f engine installation kit engine key part no. part name qty serial no. remarks 1 re504667 wiring harness 1 (20 ft) (24v) 2 ah130222 clamp 2 3 19m7788 screw 2 m12 x 25 4 14m7296 flange nut 1 m10 5 re500805 wiring harness 1 6 re500927 wire 1 7 r44302 tie band 1 8 engine controller na 9 r72659 clamp 1 10 r500488 isolator 3 11 r72659 clamp 3 19m7783 screw 3 m10 x 16 12 bracket na 13 screw na 14 screw na 15 washer na re519876 accelerator 1 (hanging) re519877 accelerator 1 (foot) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9600-9613 pn=587 p r o o f p r o o f engine installation kit memoranda memoranda memoranda memoranda memoranda memoranda 9600-9614 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=588 p r o o f p r o o f field installed kits sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8067 -un-15aug01 9701 - 9701 - 9700 - 9700 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 7402 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9700-a01 pn=589 p r o o f p r o o f field installed kits sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8068 -un-15aug01 9701 - 9701 - 9700 - 9700 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 7402 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9701 - 9700-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=590 p r o o f p r o o f field installed kits 9701 blower fan 9701 ventilateur aspirant / ventilateur soufflant 9701 saugluefter / druckluefter 9701 aspirazione ventilatore / ventilator soffiante 9701 ventilador aspiracion / ventilador soplador (9701) 9701 suglaekt / tryckflaekt rgp2423 -un-01jan94 engine key part no. part name qty serial no. remarks 1 r128860 hub 1 (a) r134199 spacer 1 (b) (c) r128767 hub 1 (b) (c) 2 washer na (a) (b) 3 19m7812 screw 6 (a) m10 x 100 19m8952 screw 6 (b) m10 x 160 4 re68278 blower fan 1 (a) (c) 36" 9 blade 5 kit na (a) 6 re68279 suction fan 1 (b) (c) 36" 8 blade 7 kit na (b) (a) blower souflante geblaese ventilator per circolazione d’aria circulaccion de aire flaktsdelar (b) suction aspiration ansaugung aspirazione aspiracion insugning (c) not as shown non represente nicht wie abgebildet non in fiqura dofoere de la ilustracion ejsom visad powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9700-9701 pn=591 p r o o f p r o o f field installed kits 9701 auxiliary front drive 9701 entrainement auxiliaire avant 9701 vorderer hilfsantrieb 9701 cmmando aus. anteriore 9701 mando auxil delantera 9701 fraeme hjaelpdrivenhet rgp4914 -un-22nov02 this parts listing is continued 9700-9702 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=592 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 19m7824 screw 1 m16 x 60 2 r82459 o-ring 1 3 r130937 cover 1 4 14m7296 flange nut 4 m10 5 r128769 support 1 6 re66291 gear 1 7 r63846 snap ring 1 8 re69480 kit 1 9 r119159 bolt 4 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9700-9703 pn=593 p r o o f p r o o f field installed kits 9701 auxilliary drive kit (9 & 13 tooth spline) 9701 kit pour entrainement auxiliare (cannelure 9 et 13 dents) 9701 nebenantriebssatz (keilverzahnung mit 2 und 13 zaehnen) 9701 kit comando ausiliario (ingranaggio scanalato a 9 e 13 denti) 9701 juego de mando auxiliar (9 y 13 estrias) 9701 hjaelpdrevsats (9 och 13 kuggar) rgp4916 -un-22nov02 this parts listing is continued 9700-9704 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=594 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 r63846 snap ring 1 2 re66291 gear 1 3 r128769 support 1 4 19m7824 screw 1 m16 x 60 5 19m7789 screw 4 m12 x 30 6 r85144 cover 1 7 r501137 gasket 1 8 r130932 housing 1 9 t70176 ring 1 10 a2597r snap ring ar 2.895 mm (.114") t27432 snap ring ar 2.743 mm (.108") r96515 snap ring ar 2.450 mm (.096") r44357 shim ar 2.311 mm (.091") 11 re33466 tapered roller bearing 1 12 r130933 gear 1 13 r82459 o-ring 1 14 r130934 housing 1 (a) 15 r96935 gasket 1 16 r85145 cover 1 17 19m7784 screw 2 m10 x 20 18 14m7296 flange nut 4 m10 19 r136091 cap screw 2 20 re69482 kit 1 (a) "a" flange "a" flasque "a" flansch "a" flangia "a" brida "a" flaens powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9700-9705 pn=595 p r o o f p r o o f field installed kits 9701 auxillary drive kit 13 & 13 tooth spline 9701 kit pour entrainement auxiliare (cannelure 13 et 13 dents) 9701 nebenantriebssatz (keilverzahnung mit 13 und 13 zaehnen) 9701 kit comando ausiliario (ingranaggio scanalato a 13 e 13 denti) 9701 juego de mando auxiliar (13 y 13 estrias) 9701 hjaelpdrevsats (13 och 13 kuggar) rgp4915 -un-04nov97 this parts listing is continued 9700-9706 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=596 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 r63846 snap ring 1 2 re66291 gear 1 3 r128769 support 1 4 19m7824 screw 1 m16 x 60 5 19m7784 screw 2 (a) m10 x 20, ("a") 19m7789 screw 2 (b) 6 r123675 cover 1 7 r501137 gasket 1 8 19m7804 screw 4 m10 x 40 9 r136466 adapter 1 (b) 10 r56192 o-ring 1 (c) 11 14m7296 flange nut 4 m10 12 r130934 housing 1 (a) r96934 gasket 1 13 r82459 o-ring 1 14 r136465 gear 1 15 re33466 tapered roller bearing 1 16 a2597r snap ring ar 2.895 mm (.114") t27432 snap ring ar 2.743 mm (.108") r96515 snap ring ar 2.450 mm (.096") r44357 shim ar 2.311 mm (.091") 17 r501137 gasket 1 18 t70176 ring 1 19 r130932 housing 1 20 19m7789 screw 2 m12 x 30 21 r136091 cap screw 2 22 re500740 kit 1 (a) "a" flange "a" flasque "a" flansch "a" flangia "a" brida "a" flaens (b) "b" flange "b" flasque "b" flansch "b" flangia "b" brida "b" flaens (c) "b" flange to "a" flange "b" flasque - "a" flasque "b" flansch - "a" flansch "b" flangia - "a" flangia ’b" brida - "a" brida "b" flaens - "a" flaens powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9700-9707 pn=597 p r o o f p r o o f field installed kits 9701 radiator/shroud/guard 9701 radiateur/hotte/garant 9701 kuehler/luefterhaube/schutz 9701 radiatore/protezione 9700 radiator/coraza/proteccion 9701 kylare/luftledare/skydd rgp5096 -un-28jan99 this parts listing is continued 9700-9708 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=598 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 19h3411 cap screw 11 3/8" x 1-1/8" 2 24h1309 washer 11 13/32" x 1-1/16" x 0.120" 3 re504405 guard 1 4 re504953 shroud 1 5 re500726 filler cap 1 6 re68640 radiator 1 7 at13740 drain valve 1 8 r117080 radiator hose 1 (low) 9 r133200 structural tubing 1 (low) 10 r122290 hose 1 (up) 11 r133199 tube 1 (up) 12 ty22472 clamp 4 (low) 13 ty22473 clamp 4 (up) 14 12h302 lock washer na 1/4" 15 19h3411 cap screw 12 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 9700-9709 pn=599 p r o o f p r o o f field installed kits 9701 charged air cooler parts for field installation 9701 systemes德州约翰迪尔皮带R135193信息,伊春约翰迪尔燃油输油泵RE68345一级代理,宜春约翰迪尔强鹿柴油发动机凸轮随动件价格,晋中johndeere约翰迪尔强鹿柴油机曲轴瓦批发,本溪JohnDeere凸轮轴R522884信息,徐州强鹿4045柴油机节温器哪里买,哈尔滨约翰迪尔挖掘机电脑板供应商,铜川johndeere约翰迪尔强鹿柴油发动机气门座圈厂家价格,许昌强鹿柴油发动机活塞RE70688的价格,白山约翰迪尔强鹿3029柴油机喷油器市场报价,白城强鹿3029柴油机止推轴承诚信推荐,巴音郭楞约翰迪尔柴油发动机活塞环市场报价,盘锦约翰迪尔6090柴油机曲轴齿轮厂家供应,延边约翰迪尔发动机电子泵代理,鹤岗约翰迪尔强鹿曲轴齿环R28811的价格,牡丹江强鹿活塞缸套组件RE516228找哪家,金华约翰迪尔6090柴油机加大止推轴承瓦批发价, d’admission d’air (hf) 9701 luftansaugsysteme (hf) 9701 sistemi delle prese d’aria (hf) 9701 sistemas de admision de aire (hf) 9701 luftintagssystem (hf) rgp8006 -un-15aug01 this parts listing is continued 9700-9710 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=600 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 re500362 structural tubing 1 (rear) 2 re500363 structural tubing 1 (front) 3 b28400 bushing 2 4 19h1900 cap screw 15 5/16" x 3/4" 5 24h1243 washer 6 11/32" x 5/8" x 1/16" 6 aw19033 strap 2 7 re509325 clamp 7 8 re500365 pipe 3 9 re68638 air cooler 1 10 99m7102 clamp 1 (lower) 11 r505512 bracket 1 12 r504637 structural tubing 1 13 19m7785 screw 2 m10 x 25 14 re509324 clamp 1 15 r500495 hose 1 16 24m7054 washer 1 6.400 x 12 x 1.600 mm 17 19m8538 cap screw 1 m6 x 45 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 9700-9711 pn=601 p r o o f p r o o f field installed kits 9701 compres*** kit (tubes only) 9701 pieces de compresseur 9701 kompres***teile 9701 parti del compres***e 9701 piezas del compre*** 9701 kompres***delar rgp4912 -un-27may97 this parts listing is continued 9700-9712 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=602 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 r500216 tube 1 (34 cfm) r132808 tube 1 (13.2/15 cfm) r53811 hose 1 (34 cfm) 2 ty22467 clamp 8 3 r129607 hose 1 (13.2/15 cfm) r130625 hose 1 (34 cfm) 4 r75562 adapter 2 (13.2/15 cfm) 5 r26375 o-ring 2 (13.2/15 cfm) 6 t20900 hose 1 7 m45937 elbow fitting 1 8 t70176 ring 1 9 r136091 cap screw 2 10 r26375 o-ring 2 (13.2/15 cfm) 11 r75562 adapter 2 (13.2/15 cfm) r42312 hose fitting 2 (34 cfm) r500612 adapter 1 12 t53268 bolt 1 (13.2/15 cfm) 13 r59873 hose fitting 1 (13.2/15 cfm) t27077 hose fitting 1 (34 cfm) 14 r113490 hose 1 (13.2/15 cfm) 15 r500185 support 1 16 19m7783 screw 1 m10 x 16 19m7785 screw 1 (34 cfm) 17 r129608 hose 1 18 r39503 fitting 2 19 t37796 hose fitting 1 20 r500574 suction hose 1 21 re500778 kit 1 re46684 plug 1 (34 cfm) 14m7299 flange nut 2 (includes re500778) 42m7071 stud 2 (includes re500778) r108661 hose 1 (not shown) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9700-9713 pn=603 p r o o f p r o o f field installed kits 9701 instrument panel 9701 tableau de bord 9701 instrumententafel 9701 cruscotto 9701 tablero de instrumentos 9701 instrumentbraeda rgp7993 -un-15aug01 this parts listing is continued 9700-9714 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=604 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 re162450 wiring harness 1 2 ah126657 isolator 4 3 re162418 pressure gauge 1 4 re68155 gauge 1 5 t135241 plug 3 6 r502862 plug 1 7 ae21116 fuse holder 1 at28061 fuse 1 (5 amp) 8 r502861 plug 1 9 t153119 plug 1 10 ar58126 key switch 1 (includes ar51481) r44342 nut 1 a4827r washer 1 11 24m7055 washer 2 12h297 lock washer 2 19h1919 cap screw 2 14h673 nut 2 12 re163465 switch 1 (a) 13 re505259 wiring harness 1 14 re162425 switch 1 (b) 15 re162424 switch 1 (c) 16 re162423 switch 1 (d) 17 re162419 tachometer 1 (3000 rpm) re154737 tachometer 1 (12/24v) 18 re162416 temperature gauge 1 19 re162429 instrument panel 1 20 re162427 travel warning alarm 1 21 re162422 voltmeter 1 (12v) re163277 voltmeter 1 (24v) 22 re163436 meter 1 23 re162449 dimmer switch 1 24 re69667 accelerator 1 25 re503681 wiring harness 1 24v to 12v 26 re162448 converter 1 27 r132486 lens 1 28 r132094 bulb 1 (12v) r132093 bulb 1 (24v) 29 re67334 wiring harness 1 (12v) 30 re162423 switch 1 31 re162424 switch 1 32 re162425 switch 1 33 re508626 instrument panel 1 34 re506969 wiring harness 1 (12 ft. extension) m115279 plug ar (a) override shutdown (b) idle select intervention prioritaire sur l’arret choix du ralenti abstelluebersteuerung leerlaufwahl inibizione di arresto selezione regime minimo anulacion de parada seleccion de velocidad de ralenti foeretraedesavstaengning val av tomgaang (c) bump enable (d) speed select activation tapotement choix des vitesses stossfreigabe drehzahlwahl abilitazione di spostamento con un colpetto selezione regime activacion de cambio por golpeteo seleccion de velocidad istaandsaettning av vaexling genom knuffning val av varvtal powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 9700-9715 pn=605 p r o o f p r o o f field installed kits 9701 power take off - in line 9701 carter de prise de force 9701 zapfwellengehaeuse 9701 alloggiamento della presa di forza 9701 caja de la toma de fuerza 9701 kraftuttagskaapa rgp140 -un-01jan94 this parts listing is continued 9700-9716 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=606 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 r53309 shaft 1 2 26h85 shaft key 2 1/4" x 1" 3 jd7849 lubrication fitting 2 4 r53311 nut 1 5 jd7759 lubrication fitting 3 6 21h1352 screw 2 1/4" x 3/8" 7 r53342 plate 1 8 r53343 gasket 1 9 r53308 set screw 1 10 r65974 shaft 1 11 ar85423 ball bearing 1 12 r65975 snap ring 1 (in-line) 13 r65976 retainer 1 14 r53307 plate 1 15 12h291 lock washer 1 5/16" 16 19h2020 cap screw 1 5/16" x 1/2" 17 f3220r lock nut 2 18 12h303 lock washer 2 5/16" 19 ar88446 bearing 2 20 r65968 sleeve 1 21 r65961 spring 4 22 ar85424 hose 1 23 19h2539 cap screw 2 3/8" x 2-1/4" 24 r53339 lever 1 25 12h331 lock washer 1 3/8" 26 19h1651 cap screw 1 3/8" x 1-1/2" 27 12h331 lock washer 2 3/8" 28 19h1732 cap screw 2 3/8" x 1-1/4" 29 ar88447 yoke 1 30 12h293 lock washer 1 7/16" 31 19h2731 cap screw 12 7/16" x 1-3/8" 32 r65973 housing 1 (sae no. 1) 33 r65980 shaft key 1 34 r65965 pin 1 35 r65963 lock 1 36 21h1300 screw 1 0.190" x 3/8" 37 12h246 lock washer 1 0.190" 38 r65964 spring 1 39 ar88445 ring 1 40 r65966 washer 1 41 r65957 plate 1 42 ar85422 clutch disk 2 43 r65956 plate 1 44 r65972 ring 1 45 r65981 shaft key 1 46 r65955 housing 1 47 r65979 washer 1 48 r65978 nut 1 49 ar85425 ball bearing 1 50 r41049 cap screw 8 51 r65967 screw 3 52 t11081 snap ring 8 53 r65960 snap ring 4 54 24h1625 washer 8 17/32" x 1" x 0.120" 55 r65959 pin fastener 4 56 r65958 lever 4 57 r65970 link 8 58 r65971 pin fastener 8 59 ar85418 power-takeoff 1 (in-line load) (fi) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9700-9717 pn=607 p r o o f p r o o f field installed kits 9701 power take off - side load 9701 carter de prise de force 9701 zapfwellengehaeuse 9701 alloggiamento della presa di forza 9701 caja de la toma de fuerza 9701 kfratuttagskaapa rgp2663 -un-01jan94 this parts listing is continued 9700-9718 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=608 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 r53309 shaft 1 2 26h85 shaft key 2 1/4" x 1" 3 jd7849 lubrication fitting 2 4 r53311 nut 1 5 jd7759 lubrication fitting 3 6 21h1352 screw 2 1/4" x 3/8" 7 r53348 plate 1 8 r53343 gasket 1 9 r53308 set screw 1 10 jd8248 bearing cup 2 11 jd8951 bearing cone 2 12 r65983 shaft 1 13 r65984 retainer 1 14 r53307 plate 1 15 12h291 lock washer 1 5/16" 16 19h2020 cap screw 1 5/16" x 1/2" 17 f3220r lock nut 2 18 12h303 lock washer 2 5/16" 19 ar88446 bearing 2 20 r65968 sleeve 1 21 r65961 spring 4 22 ar85424 hose 1 23 19h2539 cap screw 2 3/8" x 2-1/4" 24 r53339 lever 1 25 12h331 lock washer 1 3/8" 26 19h1800 cap screw 1 3/8" x 1-1/2" 27 12h331 lock washer 2 3/8" 28 19h1732 cap screw 2 3/8" x 1-1/4" 29 ar88447 yoke 1 30 12h304 lock washer 12 3/8" 31 19h3483 cap screw 12 3/8" x 1-1/8" 32 r65982 housing 1 (sae no. 1) 33 r65980 shaft key 1 34 r65965 pin 1 35 r65963 lock 1 36 21h1300 screw 1 0.190" x 3/8" 37 12h246 lock washer 1 0.190" 38 r65964 spring 1 39 r65962 ring 1 40 r65966 washer 1 41 r65957 plate 1 42 ar85422 clutch disk 2 43 r65956 plate 1 44 r65972 ring 1 45 r65955 housing 1 46 r65979 washer 1 47 r65978 nut 1 48 ar85427 ball bearing 1 49 r65981 shaft key 1 50 r41049 cap screw 8 51 r65967 screw 3 52 t11081 snap ring 8 53 r65960 snap ring 4 54 24h1625 washer 8 17/32" x 1" x 0.120" 55 r65959 pin fastener 4 56 r65958 lever 4 57 r65970 link 8 58 r65971 pin fastener 8 59 七台河勃利县威尔逊柴油发电机凸轮从动件采购批发平台,宣城旌德县VOLVO输油泵有哪些,安庆太湖县卡特发动机控制器ecm大家推荐的日昕-英珀威,郑州二七珀金斯1004柴油发电机维修保养配件去哪买?,山西长治沁县卡特奥林匹亚GEP10-80KW柴油发电机销售查询中心,平顶山汝州CAT3406柴油机配件电子转速表9X1117解决方案?,遵义汇川perkins404D-22配件中国销售中心,(provided with engine from factory)—torque . 197 n?m (145 lb-ft) 2. attach jdg23 engine lifting sling (a) to engine lifting straps (b)&to overhead hoist/floor crane. continued on next page ctm86 (20mar01) 02-010-3 powertech? 8.1 l diesel engines — base engine 032001 pn=49 engine rebuild 02 010 4 dpsg,ouo1004,902 –19–13dec00–2/2 note: if engine lifting straps are misplaced, they should be procured through service parts or servicegard?. use of an engine lifting sling (as shown) is the only approved method for lifting engine. important: lifting straps are designed to lift the engine&small acces***ies such as hydraulic pumps&air compres***s mounted to the engine auxiliary gear drive,/belt-driven components, such as air conditioning compres***s and alternators. if larger components, such as pto’s, transmissions, generators or air compres***s, are attached to other locations on the engine, the lift straps provided with the engine are not intended for this purpose. technician is responsible for providing adequate lifting devices under these situations. see machine technical manual for additional information on removing engine from machine. 3. carefully lift engine to desired location. servicegard is a trademark of deere & company rg,rg34710,1047 –19–23oct97–1/1 clean engine 1. cap/plug all openings on engine. if electrical components (starter, alternator, etc.) are not removed prior to cleaning, cover with plastic&tape securely to prevent moisture from entering. 2. steam-clean engine thoroughly. important: never steam clean/pour cold water on an injection pump while it is still warm. to do so may cause seizure of pump parts. ctm86 (20mar01) 02-010-4 powertech? 8.1 l diesel engines — base engine 032001 pn=50 engine rebuild 02 010 5 rg,rg34710,1048 –19–23oct97–1/1 disconnect turbocharger oil inlet line rg7407 –un–03nov97 turbocharger oil inlet line a—turbocharger oil inlet line 1. drain all engine oil&coolant, if not previously done. important: when servicing turbocharged engines on a rollover stand, disconnect turbocharger oil inlet line (a) from oil filter housing/turbocharger before rolling engine over. failure to do so may cause a hydraulic lock upon starting engine. hydraulic lock may cause possible engine failure. hydraulic lock occurs when trapped oil in the oil filter housing drains through the turbocharger, the exhaust and intake manifolds,&then into the cylinder head. after starting the engine, the trapped oil in the manifold&head is released into the cylinder(s) filling them with oil causing hydraulic lock&possible engine failure. 2. disconnect turbocharger oil inlet line at turbocharger or oil filter base. ctm86 (20mar01) 02-010-5 powertech? 8.1 l diesel engines — base engine 032001 pn=51 engine rebuild 02 010 6 rg,rg34710,1049 –19–08jun99–1/2 mount engine on repair stand rg8770 –un–08dec97 mounting engine on repair stand continued on next page ctm86 (20mar01) 02-010-6 powertech? 8.1 l diesel engines — base engine 032001 pn=52 engine rebuild 02 010 7 rg,rg34710,1049 –19–08jun99–2/2 rg10054 –un–23jun99 engine on repair stand caution: never remove the overhead lifting equipment until the engine is securely mounted onto the repair stand&all mounting hardware is tightened to specified torque. always release the overhead lifting equipment slowly. note: if starter motor/crankshaft driven auxiliary drive acces***y is to be removed from engine, remove before mounting engine onto repair stand. 1. mount the starter side of the engine to the engine adapter with four sae grade 8 (or higher grade) cap screws in the following sizes: engine-to-stand cap screws 6081at001 5/8-11unc x 2-1/2 in. 6081tdw01 5/8-11unc x 2-1/2 in. 6081trw01 5/8-11unc x 2-1/2 in. 6081trw02 5/8-11unc x 2-1/2 in. 6081trw09 5/8-11unc x 2-1/2 in. 6081trw10 5/8-11unc x 2-1/2 in. 6081trw11 5/8-11unc x 2-1/2 in. all other 6081 engines . 5/8-11unc x 3-1/2 in. 2. tighten cap screws to 203 n?m (150 lb-ft). 3. carefully remove lift sling from engine. to remove engine from repair stand, reverse the installation procedure. to install engine in vehicle, refer to machine technical manual. ctm86 (20mar01) 02-010-7 powertech? 8.1 l diesel engines — base engine 032001 pn=53 engine rebuild 02 010 8 rg,rg34710,1050 –19–19may99–1/1 engine disassembly sequence for overhaul the following sequence is suggested when complete disassembly for overhaul is required. refer to the appropriate repair group when removing individual engine components. 1. drain all coolant&engine oil. check engine oil for metal contaminates. 2. remove turbocharger oil inlet line&oil return line. remove turbocharger. 3. remove fan pulley&coolant manifold assembly. 4. remove coolant pump assembly from timing gear cover. note: do not damage option code label (if equipped), when removing rocker arm cover. 5. remove breather hose from rocker arm cover. remove rocker arm cover. remove carrier, if equipped. 6. remove rocker arm assembly(ies)&push rods. identify parts for reassembly. 7. remove front crankshaft pulley&damper assembly. 8. remove fuel injection lines, fuel connectors, and injection nozzles. 9. remove engine oil filter, filter base,&valve housing. 10. remove fuel filter&mounting base. remove injection pump gear cover&remove injection pump. remove all remaining fuel lines. 11. remove high pressure common rail, if equipped. 12. remove engine oil cooler assembly. 13. remove front&rear exhaust manifolds. 14. remove air intake manifold. note: always bolt down liners when rotating engine flywheel with cylinder head removed. 15. remove cylinder head with assembly. remove head gasket. 16. revolve engine on repair stand&remove engine oil pump assembly. 17. remove front timing gear cover. 18. revolve engine to vertical position. remove pistons&connecting rods. identify for reassembly. perform bearing-to-journal wear checks with plastigage?. 19. on sae no. 3 flywheel housings, remove flywheel housing&then remove flywheel. 20. on sae no. 1&2 flywheel housings, remove flywheel&then remove flywheel housing. 21. remove main bearing caps&remove crankshaft. perform bearing-to-journal wear checks with plastigage?. 22. remove camshaft&cam followers. identify for reassembly. 23. revolve engine to horizontal position, remove liners, o-rings,&packings. mark liners for reassembly in same bore from which removed. 24. remove piston cooling orifices from cylinder block. 25. remove any sen***s/gauges, cylinder block plugs and engine serial number plate, if block is to be put in a “hot tank”. 26. refer to appropriate group for inspection and repair of engine components. plastigage is a registered trademark of dana corp. ctm86 (20mar01) 02-010-8 powertech? 8.1 l diesel engines — base engine 032001 pn=54 engine rebuild 02 010 9 rg,rg34710,1051 –19–23oct97–1/2 sealant application guidelines listed below are sealants which have been tested and are used by the john deere factory to control leakage and assure hardware retention. always use the following recommended sealants when assembling your john deere diesel engine to assure quality performance. loctite? thread sealants are designed to perform to sealing standards with machine oil residue present. if excessive machine oil/poor cleanliness quality exists, clean with solvent. refer to john deere merchandise&parts sales manual for ordering information. ar31790 scotch-grip? ec1099 plastic adhesive: ? ar31790 118 ml (4 oz) rocker arm cover gasket loctite? 242—thread lock & sealer (medium strength) (blue): ? ty9370 6 ml (0.2 oz) tube ? t43512 50 ml (1.7 oz) bottle plugs&fittings: fuel filter base, intake manifold, cylinder block (oil galley). injection pump timing hole plug. cap screws: injection pump access cover, electronic tachometer cover, oil filler inlet, oil filter adapter, flywheel, coolant manifold. oil pressure sending unit. loctite? 592 pipe sealant with teflon? (white): ? ty9374 6 ml. (0.2 oz) tube ? ty9375 50 ml. (1.7 oz) bottle pipe plugs: cylinder block (coolant manifold), thermostat housing, air intake manifold,&coolant pump. coolant pump&block coolant drain valves injection pump governor cover fitting (fuel return) fuel filter drain&bleed plugs threaded nipples&elbows in coolant pump housing temperature sending unit&switch oil pan (drain hose, drain valve&elbow) connectors: turbo line&turbo drain adapter fitting for turbo oil inlet line loctite? 680 retaining compound (green): ? ty15969 50 ml. (1.7 oz) bottle expansion (frost) plugs in cylinder block wear sleeve-to-crankshaft permatex aviation (form-a-gasket no. 3): ? ty6299 227 g (8oz) container rear camshaft bore steel cap plug oil pan gasket surfaces pt569 never-seez? compound: ? pt569 227 g (8 oz) brush ? pt506 453 g (16 oz) spray loctite is a registered trademark of loctite corp. scotch-grip is a registered trademark of 3m co. teflon is a registered trademark of du pont co. never-seez is a registered trademark of emhart chemical group. ctm86 (20mar01) 02-010-9 powertech? 8.1 l diesel engines — base engine 032001 pn=55 continued on next page engine rebuild 02 010 10 rg,rg34710,1051 –19–23oct97–2/2 cap screws: turbocharger mounting&aftercooler cover. cap screws: reinstallation of special 12-point flange head cap screws on exhaust manifold of 8000 series tractors.1 injection nozzle gland nut threads&barrel loctite? 51048 moly paste camshaft nose (gear installation) loctite is a registered trademark of loctite corp. 1special 12-point flange head cap screws have pre-applied anti-sieze compound. apply additional compound for reuse only. ctm86 (20mar01) 02-010-10 powertech? 8.1 l diesel engines — base engine 032001 pn=56 engine rebuild 02 010 11 rg,rg34710,1052 –19–08jun99–1/3 6081 engine assembly sequence after overhaul the following assembly sequence is suggested when engine has been completely disassembled. be sure to check run-out specifications, clearance tolerances, torques, etc. as engine is assembled. refer to the appropriate repair group when assembling engine components. 6081 engine assembly sequence after overhaul serial number ( —199,999) 1. install all plugs in cylinder block that were removed to service block. install engine serial number plate. 2. install piston cooling orifices. 3. install cylinder liners without o-rings&measure liner stand-out. install liner o-rings in block and packings on liners. install liners. note: if new piston&liner kit assemblies are being installed, install the crankshaft first. 4. install main bearings&crankshaft. rotate crankshaft to assure correct assembly. check crankshaft end play. note: always bolt liners down before rotating engine with cylinder head removed. if installing new piston/liner kits, assemble kits onto the respective connecting rods using new snap rings. bolt liners down as each kit is installed. 5. install engine flywheel&housing, if applicable: ? sae 3: flywheel goes on before housing. ? sae 1&sae 2: housing goes on before flywheel. 6. install piston&rod assemblies. bolt liners down after each piston assembly is installed. 7. install crankshaft rear oil seal housing&check runout. install rear oil seal&wear sleeve. 8. install cam followers in hole from which originally removed. 9. install camshaft. align timing marks (camshaft-to-crankshaft gears) with no. 1 piston at “tdc” compression stroke. 10. install engine oil pump assembly. 11. install fuel injection pump&drive gear. 12. install engine oil cooler assembly. 13. install filter base, valve housing,&new oil filter. 14. install cylinder head, push rods,&rocker arm assembly. measure valve lift&adjust valve clearance. 15. install rocker arm cover. install breather hose. 16. install air intake manifold. 17. install front&rear exhaust manifolds. 18. install timing gear cover. install front crankshaft wear sleeve&oil seal. 19. install coolant pump assembly&coolant manifold. 20. install turbocharger. install turbocharger oil inlet line&oil return line. 21. install fuel injection nozzles&delivery line assembly. 22. install fuel filter base, supply lines,&filter. 23. install front pulley&new damper as an assembly. 24. install fan pulley assembly. install starter motor. ctm86 (20mar01) 02-010-11 powertech? 8.1 l diesel engines — base engine 032001 pn=57 continued on next page engine rebuild 02 010 12 rg,rg34710,1052 –19–08jun99–2/3 25. fill engine with clean oil. install dipstick. 26. flush cooling system&refill with proper coolant. 27. perform engine break-in&normal standard performance checks. see engine break-in guidelines later in this group. 6081 engine assembly sequence after overhaul serial number (200,000— ) 1. install all plugs in cylinder block that were removed to service block. install engine serial number plate. 2. install piston cooling orifices. 3. install cylinder liners without o-rings&measure liner stand-out. install liner o-rings in block and packings on liners. install liners. note: if new piston&liner kit assemblies are being installed, install the crankshaft first. 4. install main bearings&crankshaft. rotate crankshaft to assure correct assembly. check crankshaft end play. note: always bolt liners down before rotating engine with cylinder head removed. if installing new piston/liner kits, assemble kits onto the respective connecting rods using new snap rings. bolt liners down as each kit is installed. 5. install engine flywheel&housing, if applicable: ? sae 3: flywheel goes on before housing. ? sae 1&sae 2: housing goes on before flywheel. 6. install piston&rod assemblies. bolt liners down after each piston assembly is installed. 7. install crankshaft rear oil seal housing&check runout. install rear oil seal&wear sleeve. 8. install cam followers in hole from which originally removed. 9. install camshaft. align timing marks (camshaft-to-crankshaft gears) with no. 1 piston at “tdc” compression stroke. 10. install engine oil pump assembly. 11. install high pressure common rail. 12. install fuel injection pump&drive gear. 13. install engine oil cooler assembly. 14. install fuel filter base, supply lines,&filter. 15. install oil filter base, valve housing,&new oil filter. 16. install cylinder head, push rods, rocker arm assemblies, electronic injectors,&fuel connectors. 17. install carrier, rocker arm cover,&breather hose. 18. install air intake manifold. 19. install front&rear exhaust manifolds. 20. install timing gear cover. install front crankshaft wear sleeve&oil seal. 21. install coolant pump assembly&coolant manifold. 22. install turbocharger. install turbocharger oil inlet line&oil return line. 23. install fuel leak-off lines&high pressure fuel delivery lines. 24. install front pulley&new damper as an assembly. 25. install fan pulley assembly. install starter motor. 26. fill engine with clean oil. install dipstick. 27. flush cooling system&refill with proper coolant. ctm86 (20mar01) 02-010-12 powertech? 8.1 l diesel engines — base engine 032001 pn=58 continued on next page engine rebuild 02 010 rg,rg34710,1052 –19–08jun99–3/3 28. perform engine break-in&normal standard performance checks. see engine break-in guidelines later in this group. 13 rg,rg34710,1053 –19–23oct97–1/1 engine break-in guidelines engine break-in should be performed after overhaul or when the following repairs have been made: main bearings, rod bearings, crankshaft,/any combination of these parts have been replaced. pistons, rings,/liners have been replaced. rear crankshaft oil seal&wear sleeve have been replaced. (primary objective is to see if oil seal still leaks). cylinder head has been removed. (check&reset valve clearance.) injection pump has been removed/critical adjustments have been made while it is on the engine. (primary objective is to check power). ctm86 (20mar01) 02-010-13 powertech? 8.1 l diesel engines — base engine 032001 pn=59 engine rebuild 02 010 14 rg,100,jw7645 –19–21nov97–1/3 perform engine break-in rg7359 –un–20jun00 check engine oil level rg5895 –un–13aug91 engine oil level dipstick use a dynamometer to perform the following preliminary break-in procedure. if necessary, preliminary engine break-in can be performed without a dynamometer if under controlled operating conditions. important: do not use john deere plus-50 oil or engine oils meeting api cg4, api cf4, acea e3/acea e2, performance levels during break-in period of an engine that has had a major overhaul. these oils will not allow an overhauled engine to properly wear during the break-in period. do not add makeup oil until the oil level is below the add mark. john deere break-in oil should be used to make up any oil consumed during break-in period. do not fill above the crosshatch pattern/full mark. oil levels anywhere within the crosshatch are acceptable. 1. fill engine crankcase to proper level with john deere engine break-in oil during break-in operation. use break-in oil regardless of ambient temperature. this oil is specifically formulated to enhance break-in of john deere diesel engines. under normal conditions, do not exceed 100 hours with break-in oil. if john deere engine break-in oil is not available, use diesel engine oil meeting api service classification ce or acea specification e1. important: during preliminary break-in, periodically check engine oil pressure&coolant temperature. also check for signs of fuel, oil,/coolant leaks. 2. start engine, run at loads&speeds shown in following chart for time limits given. ctm86 (20mar01) 02-010-14 powertech? 8.1 l diesel engines — base engine 032001 pn=60 continued on next page engine rebuild 02 010 15 rg,100,jw7645 –19–21nov97–2/3 preliminary engine break-in after major overhaul time load engine speed 1 minute no load 850 rpm 2 minutes no load fast idle 15 minutes 1/2—3/4 load 2000 rpm to rated speed 10 minutes full load rated speed 3. after preliminary break-in, run engine 1—2 minutes at 1500 rpm, with no load before shut-down. 4. check&readjust valve clearance as necessary. cylinder head retorque is not required. note: during the first 20 hours, avoid prolonged periods of engine idling/sustained maximum load operation. if engine will idle longer than 5 minutes, stop engine. 5. operate the engine at heavy loads with minimal idling during the break-in period. if the engine has significant operating time at idle, constant speeds, and/or light load usage, an additional 100 hour break-in period is recommended using a new change of john deere engine break-in oil&new john deere oil filter. check engine oil level more frequently during engine break-in period. as a general rule, makeup oil should not need to be added during 100-hour break-in period. however, if makeup oil is required in the first 100-hour break-in, an additional 100-hour break-in period is required. use a new change of john deere engine break-in oil&a new john deere oil filter. after 100 hours maximum, drain break-in oil&change oil filter. fill crankcase with john deere torq-gard supreme?/plus-50?/other heavy-duty diesel engine oil within the same service classification as recommended in this manual. see diesel engine oil in group 002, fuels, lubricants,&coolant. torq-gard supreme is a registered trademark of deere & company. plus-50 is a registered trademark of deere & company. ctm86 (20mar01) 02-010-15 powertech? 8.1 l diesel engines — base engine 032001 pn=61 continued on next page engine rebuild 02 010 16 rg,100,jw7645 –19–21nov97–3/3 note: some increase in oil consumption may be expected when low viscosity oils are used. check oil levels more frequently. if air temperature is below -10° c (14° f), use an engine block heater. rg,rg34710,1055 –19–23oct97–1/1 check crankcase ventilation system rg5797 –un–26nov97 a—crankcase vent tube crankcase vent tube 1. inspect crankcase ventilation system for restrictions. lack of ventilation causes sludge to form in crankcase. this can lead to clogging of oil passages, filters, and screens, resulting in serious engine damage. 2. clean crankcase vent tube (a) with solvent and compressed air if restricted. install&tighten hose clamps securely. rg,rg34710,1056 –19–23oct97–1/1 check air intake system rg4689 –un–20dec88 air intake hose clamps a—hose clamps 1. replace air cleaner primary filter element. (see operator’s manual.) replace secondary element if primary element has holes in it. 2. check condition of air intake hose(s). replace hoses that are cracked, split,/otherwise in poor condition. 3. check hose clamps (a) for tightness. replace clamps that cannot be properly tightened. this will help prevent dust from entering the air intake system which could cause serious engine damage. ctm86 (20mar01) 02-010-16 powertech? 8.1 l diesel engines — base engine 032001 pn=62 engine rebuild 02 010 17 rg,rg34710,1057 –19–23oct97–1/1 check exhaust system 1. inspect exhaust system for leaks/restrictions. check manifold for cracks. repair/replace as necessary. 2. check that turbocharger-to-exhaust elbow adapter clamps are securely tightened&do not leak. 3. check exhaust stack for evidence of oil leakage past valve stem seals. oil in exhaust stack may be caused by excessive valve stem-to-guide clearance/excessive light load engine idling. rg,rg34710,1058 –19–23oct97–1/2 check&service cooling system rg7061 –un–26nov97 cooling system weep hole with foam filter a—weep hole 1. remove trash that has accumulated on/near radiator. 2. visually inspect entire cooling system&all components for leaks/damage. repair/replace as necessary. 3. remove the foam filter from weep hole (a, shown removed) located on the side of timing gear cover and discard filter. inspect the weep hole for any restrictions. 4. insert a heavy gauge wire deep into weep hole to make sure hole is open. 5. install new foam filter flush with timing gear cover. continued on next page ctm86 (20mar01) 02-010-17 powertech? 8.1 l diesel engines — base engine 032001 pn=63 engine rebuild 02 010 18 rg,rg34710,1058 –19–23oct97–2/2 ts281 –un–23aug88 service cooling system safely rg7044 –un–26nov97 coolant pump drain valve rg7143 –un–26nov97 cylinder block coolant drain valve a—coolant pump drain valve b—block drain valve caution: do not drain coolant until the coolant temperature is below operating temperature. always loosen coolant pump drain valve (a) and block drain valve (b) slowly to relieve any excess pressure. important: both coolant pump drain valve and block drain valve must be opened to completely drain the engine. 6. remove&check thermostat(s). see remove and test thermostats in group 070. 7. drain&flush cooling system. see flush and service cooling system in group 002. important: air must be expelled from cooling system when system is refilled. loosen temperature sending unit fitting at rear of cylinder head, bleed plug at top front of cylinder head,/plug in thermostat housing to allow air to escape when filling system. retighten fitting/plug when all the air has been expelled. 8. fill cooling system with coolant. see diesel engine coolant in group 002. 9. run engine until it reaches operating temperature. check entire cooling system for leaks. 10. after engine cools, check coolant level. note: coolant level should be even with bottom of radiator filler neck. 11. check system for holding pressure. see pressure test cooling system&radiator cap in group 150. ctm86 (20mar01) 02-010-18 powertech? 8.1 l diesel engines — base engine 032001 pn=64 engine rebuild 02 010 19 rg,rg34710,1059 –19–23oct97–1/2 check electrical system ts204 –un–23aug88 prevent battery explosions caution: battery gas can explode. keep sparks&flames away from batteries. use a flashlight to check battery electrolyte level. never check battery charge by placing a metal object across the posts. use a voltmeter or hydrometer. always remove grounded (-) battery clamp first and replace it last. warning: battery posts, terminals,&related acces***ies contain lead&lead compounds, chemicals known to the state of california to cause cancer and reproductive harm. wash hands after handling. 1. clean batteries&cables with damp cloth. if corrosion is present, remove it&wash terminals with a solution of ammonia/baking soda in water. then flush area with clean water. 2. coat battery terminals&connectors with petroleum jelly mixed with baking soda to retard corrosion. 3. test batteries. if batteries are not near full charge, try to find out why. 4. on low-maintenance batteries, check level of electrolyte in each cell of each battery. level should be to bottom of filler neck. if water is needed, use clean, mineral-free water. if water must be added to batteries more often than every 250 hours, alternator may be overcharging. note: water cannot be added to maintenance-free batteries. 5. if batteries appear to be either undercharged or overcharged, check alternator&charging circuit. 6. check tension of drive belts. see checking belt tensioner spring tension&belt wear in group 070. ctm86 (20mar01) 02-010-19 powertech? 8.1 l diesel engines — base engine 032001 pn=65 continued on next page engine rebuild 02 010 20 rg,rg34710,1059 –19–23oct97–2/2 7. check operation of starter motor&gauges. note: for test&repair of alternators&starter motors, see ctm77, alternators&starting motors. ctm86 (20mar01) 02-010-20 powertech? 8.1 l diesel engines — base engine 032001 pn=66 engine rebuild 02 010 21 rg,rg34710,1061 –19–08jun99–1/1 general tune-up recommendations as a general rule, an engine tune-up is not necessary if all recommended operator’s manual hourly service procedures are performed on schedule. if your engine performance is not within the rated application guidelines, the following service procedures are recommended to help restore engine to normal operating efficiency. important: engines that are equipped with electronically-controlled governors have a diagnostic feature that will display detailed codes to alert operator of specific performance problems. refer to ctm68, electronic fuel injection systems, for diagnostic code troubleshooting procedures on bosch ecu control systems. refer to ctm134 for john deere level 3 ecu controls. refer to ctm255 for john deere level 9 ecu controls. operation detailed reference change engine oil&filters . operator’s manual lubricate pto clutch internal levers&linkage, if equipped . operator’s manual replace fuel filter . ctm134/ctm243/ctm255/operator’s manual clean crankcase vent tube . this group/operator’s manual check air intake system. replace air cleaner elements . this group/operator’s manual check exhaust system this group check&service engine cooling system this group/operator’s manual check&adjust fan&alternator belts operator’s manual check electrical system . this group check crankshaft vibration damper . group 040/operator’s manual inspect turbocharger&check turbocharger boost pressure . group 150 check fuel injection system: check engine/injection pump timing: check . ctm134/ctm243/ctm255 and adjust speed advance; clean injection nozzles,&adjust opening pressure. check engine oil pressure. correct as necessary group 150 check engine valve clearance. adjust if necessary . group 020/group 021 check engine speeds. correct as necessary . authorized servicing dealer check engine performance on dynamometer . this group ctm86 (20mar01) 02-010-21 powertech? 8.1 l diesel engines — base engine 032001 pn=67 engine rebuild 02 010 22 ctm86 (20mar01) 02-010-22 powertech? 8.1 l diesel engines — base engine 032001 pn=68 group 020 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 1 dpsg,ouo1004,829 –19–13dec00–1/4 check&adjust valve clearance serial number ( —199,999) too little valve clearance throws valves out of time. valves open too early&close too late. this causes the valves to overheat due to hot combustion gases rushing past valves when out of time. overheating lengthens valve stems which prevents proper seating of valves. the valves seat so briefly/poorly that normal heat transfer into the cooling system does not have time to take place, causing burned valves&low power. too much valve clearance causes a lag in valve timing causing engine valve train imbalance. the fuel-air mixture enters the cylinders late during intake stroke. the exhaust valve closes early&prevents waste gases from being completely removed from cylinders. also, the valves close with a great deal of impact, which may crack/break the valves&scuff the camshaft&followers. caution: to prevent accidental starting of engine while performing valve adjustments, always disconnect negative (—) battery terminal. important: valve clearance must be checked and adjusted with engine cold. 1. remove rocker arm cover with ventilator tube. important: visually inspect contact surfaces of valve tips&rocker arm wear pads. check all parts for excessive wear, breakage,/cracks. replace parts that show visible damage. rocker arms that exhibit excessive valve clearance should be inspected more thoroughly to identify damaged parts. continued on next page ctm86 (20mar01) 02-020-1 powertech? 8.1 l diesel engines — base engine 032001 pn=69 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 2 dpsg,ouo1004,829 –19–13dec00–2/4 rg7013 –un–26nov97 flywheel turning tool&timing pin a—flywheel turning tool b—timing pin 2. remove plastic plug from cylinder block bores and install jde81-1/jdg820 flywheel turning tool (a) and jde81-4 timing pin (b). 3. rotate engine with the flywheel turning tool until timing pin engages timing hole in flywheel. if the rocker arms for no. 1 (front) cylinder are loose, the engine is at no. 1 “tdc-compression.” if the rocker arms for no. 6 (rear) cylinder are loose, the engine is at no. 6 “tdc-compression.” rotate the engine one full revolution (360°) to no. 1 “tdc-compression.” continued on next page ctm86 (20mar01) 02-020-2 powertech? 8.1 l diesel engines — base engine 032001 pn=70 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 3 dpsg,ouo1004,829 –19–13dec00–3/4 rg5241 –un–06dec88 adjusting valve clearance rg4295 –19–21aug91 valve adjusting sequence 4. with engine lock-pinned at “tdc” of no. 1 piston’s compression stroke, check valve clearance on nos. 1, 3,&5 exhaust valves&nos. 1, 2,&4 intake valves. specification intake valve clearance checking (rocker arm-to-valve tip with engine cold)—clearance 0.41—0.51 mm (0.016—0.020 in.) exhaust valve clearance checking (rocker arm-to-valve tip with engine cold)— clearance 0.66—0.76 mm (0.026—0.030 in.) 5. rotate flywheel 360° until no. 6 piston is at “tdc” of its compression stroke. rocker arms for no. 6 piston should be loose. 6. check valve clearance to the same specifications on nos. 2, 4,&6 exhaust&nos. 3, 5,&6 intake valves. note: adjust valve clearance in the same sequence used for checking clearance. 7. if valve clearance needs to be adjusted, loosen the lock nut on rocker arm adjusting screw. turn adjusting screw until feeler gauge slips with a slight drag. hold the adjusting screw from turning with screwdriver and tighten lock nut to specifications. specification valve adjusting screw lock nut—torque 27 n?m (20 lb-ft) recheck clearance again after tightening lock nut and compare to the following specifications. readjust clearance as necessary. specification intake valve clearance adjustment (rocker arm-to-valve tip with engine cold)— clearance . 0.46 mm (0.018 in.) exhaust valve clearance adjustment (rocker arm-to-valve tip with engine cold)— clearance . 0.71 mm (0.028 in.) ctm86 (20mar01) 02-020-3 powertech? 8.1 l diesel engines — base engine 032001 pn=71 continued on next page cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 4 dpsg,ouo1004,829 –19–13dec00–4/4 8. install rocker arm cover&tighten cap screws to specifications. specification rocker arm cover-to-cylinder head cap screws—torque 8 n?m (6 lb-ft) (72 lb-in.) ctm86 (20mar01) 02-020-4 powertech? 8.1 l diesel engines — base engine 032001 pn=72 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 5 dpsg,ouo1004,830 –19–27apr99–1/1 check valve lift serial number ( —199,999) rg5789 –un–09aug91 checking valve lift important: for a more accurate measurement, it is recommended that valve lift be measured at 0.00 mm (in.) valve clearance&with engine cold. note: measuring valve lift can give an indication of wear on camshaft lobes&cam followers/bent push rods. 1. remove turbocharger oil inlet clamp&rocker arm cover. loosen lock nut on rocker arm. set valve clearance at 0.00 mm (in.) on valve being checked. tighten lock nut. 2. put dial indicator tip on valve rotator. be sure that valve is fully closed. 3. check pre-set on dial indicator. set dial indicator pointer at zero. 4. manually turn engine in running direction, using the engine rotation tools previously mentioned for checking valve clearance. 5. observe dial indicator reading as valve is moved to fully open position. record reading&valve number. specification intake valve—lift 13.53—13.71 mm (0.533—0.540 in.) at 0.00 mm (in.) wear tolerance 12.65 mm (0.498 in.) at 0.00 mm (in.) clearance exhaust valve—lift 14.52—14.70 mm (0.572—0.579 in.) at 0.00 mm (in.) . wear tolerance 13.64 mm (0.537 in.) at 0.00 mm (in.) clearance 6. repeat procedure on all remaining valves. 7. reset valve clearance to specification after measuring lift. see check&adjust valve clearance serial number ( —199,999) earlier in this group. ctm86 (20mar01) 02-020-5 powertech? 8.1 l diesel engines — base engine 032001 pn=73 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 6 dpsg,ouo1004,787 –19–27apr99–1/4 remove cylinder head serial number ( —199,999) ts218 –un–23aug88 service cooling system safely rg7014 –un–26nov97 removing cylinder head a—coolant manifold b—turbocharger c—intake manifold d—exhaust manifold assembly it is not necessary to remove engine from machine to service cylinder head on all applications. refer to your machine technical manual for engine removal procedure, if required. caution: after operating engine, allow exhaust system to cool before working on engine. do not drain coolant until the coolant temperature is below operating temperature. always loosen drain valve slowly to relieve any excess pressure. 1. drain engine oil&coolant. disconnect turbocharger oil inlet line at turbocharger/oil filter base. see disconnect turbocharger oil inlet line in group 010. note: if cylinder head is being removed for piston and liner repairs/any other service that does not require disassembly of head, cylinder head can be removed with coolant manifold (a), turbocharger (b), intake manifold (c),&exhaust manifold (d) installed. 2. remove coolant manifold&all coolant piping. see remove coolant manifold in group 070. 3. remove turbocharger. see remove turbocharger in group 080. remove front and rear exhaust manifold (d). see remove, inspect and install exhaust manifold in group 080. 4. remove air intake manifold. see remove, inspect and install intake manifold in group 080. 5. remove fuel injection delivery lines&injection nozzles. if mechanical fuel system, see remove fuel injection nozzles in group 090 of ctm243. if level 3 electronic fuel system, see remove fuel injection nozzles in group 090 of ctm134. ctm86 (20mar01) 02-020-6 powertech? 8.1 l diesel engines — base engine 032001 pn=74 continued on next page cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 7 dpsg,ouo1004,787 –19–27apr99–2/4 6. remove rocker arm cover with ventilator outlet hose assembly. 7. loosen all rocker arm adjusting screws before removing assembly. dpsg,ouo1004,787 –19–27apr99–3/4 rg7017 –un–26nov97 removing rocker arm assembly rg7018 –un–05dec97 removing push rods a—rocker arm shaft clamps b—rocker arm assembly 8. remove six cap screws&remove all four rocker arm shaft clamps (a). lift rocker arm assembly (b) up and remove. remove wear caps from valve stems. 9. remove all 12 push rods&identify for reassembly. note: clean&inspect push rods. see clean and inspect push rods serial number ( — 199,999) later in this group. continued on next page ctm86 (20mar01) 02-020-7 powertech? 8.1 l diesel engines — base engine 032001 pn=75 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 8 dpsg,ouo1004,787 –19–27apr99–4/4 rg5245 –un–05dec97 lifting cylinder head from block 10. remove all 26 cylinder head cap screws. discard cap screws, they are not reusable. important: do not use screwdrivers/pry bars between cylinder block&cylinder head to loosen head-to-block gasket seal. 11. lift cylinder head from block. if cylinder head sticks, use a soft hammer to tap the cylinder head. 12. remove cylinder head gasket. inspect for possible oil, coolant,/combustion chamber leaks. also, check for evidence of incorrect/defective head gasket being used. note: do not rotate crankshaft with cylinder head removed unless all cylinder liners are secured with cap screws&large flat washers as described in group 030. see remove pistons and connecting rod assemblies in group 030. ctm86 (20mar01) 02-020-8 powertech? 8.1 l diesel engines — base engine 032001