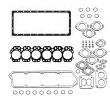

配件展示

济南JohnDeere燃油输油泵RE68345厂家供应

配件详情

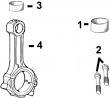

约翰迪尔 6081 低压缩活塞

|

|

|||||||||||||||||||||||||||

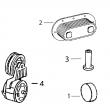

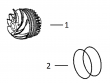

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

(3)用铝油盘使用TR49377(RE504822)。

(4)使用TR66452杆式螺栓和机器分体式连杆,并使用带断裂分体式连杆的TR501035杆式螺栓。

(5)发动机ESN 199,999及以下。 仅适用于Exaust Valves。

(6)发动机ESN 200,000及以上。 仅适用于Exaust Valves。

(7)发动机ESN 199,999及以下。

(8)发动机ESN 200,000及以上。

(9)检查应用程序是否正确使用。

(10)机器分体连杆。 使用棒螺栓TR66452。

(11)破裂的分裂连杆。 使用棒螺栓TR501035。

(12)高流量。

(13)与断裂分体连杆一起使用。

4039DFM,6068SM50 ,RE522528、RE519774、RE532628、RE518176、RE507980、RE518503、RE522515、RE504836、RE509031、RE509032、RE59754、RE507284、RE59754、RE519626、RE518977、RE508202、RE58935、T19044、RE62418、RE62419、RE521248、RE520842、C085004、AR95758、LVA10419、AH128449、RE509672、RE196945、RE191915、RE522688、RE522687、RE519774、RE532628powertech? 8.1 l diesel engines — base engine 032001 pn=419 repair tools&other materials 05 170 26 dpsg,ouo1004,840 –19–27apr99–1/1 group 050 — camshaft&timing gear train other materials number name use 51048 (loctite?) moly paste lubricate camshaft nose to provide lubrication to aid in camshaft gear installation. ty6299 (u.s.) permatex? aviation apply to camshaft bore steel cap (form-a-gasket no. 3) plug. ty6333/ty6347 (u.s.) high temperature grease used to lubricate camshaft lobes and thrust washer when installing camshaft. loctite is a registered trademark of loctite corp. permatex is a registered trademark of loctite corporation. dpsg,ouo1004,846 –19–27apr99–1/1 group 060 — lubrication system other materials number name use t43512 (u.s.) thread lock&sealer (medium coat threads of oil filter adapter. ty9473 (canadian) strength) 242 (loctite?) aviation (ty6299) (u.s.) form-a-gasket no. 3 oil pan gasket surfaces. ty9375 (u.s.) pipe sealant with teflon? to seal oil pan elbow drain fitting. ty9480 (canadian) 592 (loctite?) loctite is a registered trademark of loctite corp. permatex is a registered trademark of loctite corporation. teflon is a registered trademark of du pont co. ctm86 (20mar01) 05-170-26 powertech? 8.1 l diesel engines — base engine 032001 pn=420 repair tools&other materials dpsg,ouo1004,810 –19–21apr99–1/2 group 070 — cooling system essential tools note: order tools according to information given in the u.s. servicegard? catalog/from the european microfiche tool catalog (mtc). servicegard is a trademark of deere & company 05 170 27 dpsg,ouo1004,810 –19–21apr99–2/2 rg5120 –un–05dec97 jdg908 coolant bypass tube seal driver jdg908 used to install bypass tube seal in coolant pump cover. dpsg,ouo1004,849 –19–27apr99–1/1 group 070 — cooling system other materials number name use ty6333/ty6345 (u.s.) high-temperature grease fan drive bearings. ty9375 (u.s.) pipe sealant with teflon? coolant pump&block drain valves ty9480 (canadian)&coolant temperature switch. 592 (loctite?) t43512 (u.s.) thread lock&sealer (medium coolant manifold-to-cylinder head ty9473 (canadian) strength) cap screws. 242 (loctite?) loctite is a registered trademark of loctite corp. teflon is a registered trademark of du pont co. ctm86 (20mar01) 05-170-27 powertech? 8.1 l diesel engines — base engine 032001 pn=421 repair tools&other materials dpsg,ouo1004,817 –19–21apr99–1/2 group 080 — air intake&exhaust system essential tools note: order tools according to information given in the u.s. servicegard? catalog/from the european microfiche tool catalog (mtc). servicegard is a trademark of deere & company 05 170 28 dpsg,ouo1004,817 –19–21apr99–2/2 rg5571 –un–04jul89 jdg683 sealing ring compression tool jdg683 used to compress aftercooler sealing ring for cover-to-intake manifold alignment during assembly (6081a engines). ctm86 (20mar01) 05-170-28 powertech? 8.1 l diesel engines — base engine 032001 pn=422 repair tools&other materials 05 170 29 dpsg,ouo1004,819 –19–21apr99–1/1 group 080 — air intake&exhaust system other materials number name use pt569 (u.s.) never-seez? compound turbocharger-to-exhaust manifold cap screws,&aftercooler cover-to-intake manifold cap screws. also apply to special 12-point flange head exhaust manifold cap screws being reused on 8000 series tractors.1 never-seez is a registered trademark of emhart chemical group. 1special 12-point flange head cap screws used on exhaust manifold of 8000 series tractors have pre-applied anti-sieze compound. reapply compound only when reusing cap screws. dpsg,ouo1004,861 –19–28apr99–1/2 group 100 — starting&charging systems essential tools note: order tools according to information given in the u.s. servicegard? catalog/from the european microfiche tool catalog (mtc). servicegard is a trademark of deere & company dpsg,ouo1004,861 –19–28apr99–2/2 rw17441 –un–16nov89 jde80 starter wrench . jde80 remove&install starter motor. ctm86 (20mar01) 05-170-29 powertech? 8.1 l diesel engines — base engine 032001 pn=423 repair tools&other materials 05 170 30 ctm86 (20mar01) 05-170-30 powertech? 8.1 l diesel engines — base engine 032001 pn=424 group 180 diagnostic service tools dpsg,ouo1004,201 –19–07jul98–1/7 base engine diagnostic tools note: order tools according to information given in the u.s. servicegard? catalog/from the european microfiche tool catalog (mtc). servicegard is a trademark of deere & company 05 180 1 dpsg,ouo1004,201 –19–07jul98–2/7 rg5161 –un–23aug88 compression test set jt01674 (formerly d14546ba or fkm10021) used to check cylinder compression pressure. use adapter&gauge/hose assembly from set. dpsg,ouo1004,201 –19–07jul98–3/7 rg6612 –un–29jan93 oil galley plug tool jdg782 used to remove&install oil galley plug when measuring engine oil pressure. dpsg,ouo1004,201 –19–07jul98–4/7 rg5162 –un–23aug88 universal pressure test kit jt05470 (formerly d15027nu/fkm10002) used for testing engine oil pressure, intake manifold pressure (turbo boost),&fuel supply pump pressure. ctm86 (20mar01) 05-180-1 powertech? 8.1 l diesel engines — base engine 032001 pn=425 continued on next page diagnostic service tools dpsg,ouo1004,201 –19–07jul98–5/7 r26406n –un–29nov88 cooling system pressure pump d05104st used to pressure test radiator cap&cooling system. 05 180 2 dpsg,ouo1004,201 –19–07jul98–6/7 rg7056 –un–05dec97 flywheel turning tool jdg820 used to rotate engine flywheel to lock engine at “tdc” to check fuel injection pump timing. use with jde81-4 timing pin. dpsg,ouo1004,201 –19–07jul98–7/7 rg5068 –un–05dec97 timing pin jde81-4 used to lock engine at “tdc”. use with jdg820 flywheel turning tool. ctm86 (20mar01) 05-180-2 powertech? 8.1 l diesel engines — base engine 032001 pn=426 group 190 dealer fabricated service tools rg,rg34710,1338 –19–23oct97–1/1 how to make tools this tool can be made in a service shop using common shop tools&locally obtained materials. 05 190 1 rg,rg34710,1339 –19–23oct97–1/1 dfrg3—cylinder liner holding fixture t36748n –un–24oct88 cylinder liner holding fixture 1—254.0 mm (10 in.) 7—12.7 mm (0.5 in.) 13—0.328 in. drill through 19—101.6 mm (4 in.) 2—127.0 mm (5 in.) 8—31.8 mm (1.25 in.) 14—5/16 in.—18 tap 20—111.25 mm (4.38 in.) 3—38.1 mm (1.5 in.) 9—63.5 mm (2.5 in.) 15—2 used 21—60.45 mm (2.38 in.) 4—405.4 mm (16 in.) 10—25.4 mm (1 in.) 16—304.8 mm (12 in.) 22—5/16 in. x 1 in. cap screw 5—330.2 mm (13 in.) 11—6.35 mm (0.25 in.) 17—5/16 in.—18 tap 23—38.1 mm (1.5 in.) angle 6—9.52 mm (0.38 in.) 12—152.4 mm (6 in.) 18—69.85 mm (2.75 in.) radius iron ctm86 (20mar01) 05-190-1 powertech? 8.1 l diesel engines — base engine 032001 pn=427 dealer fabricated service tools 05 190 2 ctm86 (20mar01) 05-190-2 powertech? 8.1 l diesel engines — base engine 032001 pn=428 section 06 specifications contents page group 200—repair&general oem specifications general oem engine specifications 06-200-1 general oem engine specifications--continued 06-200-3 unified inch bolt&cap screw torque values 06-200-5 metric bolt&cap screw torque values 06-200-6 group 020 — cylinder head&valves s. n. ( —199,999) repair specifications 06-200-7 group 021 — cylinder head&valves s. n. (200,000— ) repair specifications .06-200-10 group 030 — cylinder block, liners, pistons&rods repair specifications 06-200-14 group 040 — crankshaft, main bearings and flywheel repair specifications 06-200-18 group 050 — camshaft&timing gear 06 train repair specifications 06-200-22 group 060 — lubrication system repair specifications .06-200-24 group 070 — cooling system repair specifications .06-200-27 group 080 — air intake&exhaust system repair specifications 06-200-29 group 100 — oem starting&charging systems repair specifications 06-200-30 group 210—diagnostic specifications group 150 — base engine diagnostic specifications (includes dynamometer specifications (oem)&turbocharger boost哈密约翰迪尔柴油机T20073凸轮随动件批发价,嘉峪关约翰迪尔6090柴油机活塞公司,澳门离岛约翰迪尔拖拉机发动机主线束的价格,中卫强鹿柴油机水泵RE549153价格,遵义强鹿JOHNDEERE发动机高压油泵RE47135供应商,天水强鹿柴油发电机组仪表盘哪家好,张家界johndeere约翰迪尔强鹿柴油机摇臂批发价,澳门离岛强鹿柴油机水泵信息,澳门离岛强鹿柴油机水泵供货商,营口约翰迪尔装载机发动机发电机哪家好,河南JOHNDEERE强鹿4024TF281配件批发商,随州约翰迪尔强鹿柴油发动机燃油输送泵批发价,玉树强鹿柴油发电机组喷油嘴的价格,江门约翰迪尔发动机维修保养配件厂家批发,乌海JohnDeere传感器RE522794信息,伊春强鹿滤芯滤清器RE59574代理商,上饶强鹿柴油机四配套DZ10211代理,本溪强鹿滤芯滤清器RE50455厂家批发, specifications) .06-210-1 dynamometer test specifications 06-210-2 intake manifold pressure (turbocharger boost) specifications 06-210-7 effects of altitude&temperature on engine performance 06-210-15 ctm86 (20mar01) 06-1 powertech? 8.1 l diesel engines — base engine 032001 pn=1 contents 06 ctm86 (20mar01) 06-2 powertech? 8.1 l diesel engines — base engine 032001 pn=2 group 200 repair&general oem specifications 06 200 1 rg,rg34710,4095 –19–01jan96–1/2 general oem engine specifications note: for john deere vehicle engines, see machine technical manual. item unit of measure 6081tf 6081af general data engine type —— in-line, 4 cycle diesel in-line, 4 cycle diesel aspiration —— turbocharged turbocharged, water-to-air aftercooled number of cylinders —— 6 6 bore mm (in.) 116 (4.56) 116 (4.56) stroke mm (in.) 129 (5.06) 129 (5.06) displacement l (cu in.) 8.1 (496) 8.1 (496) combustion system —— direct injection direct injection compression ratio —— 16.5:1 16.5:1 physical dimensions: width mm (in.) 599 (23.8) 698 (27.5) height mm (in.) 1138 (44.8) 1138 (44.8) length mm (in.) 1200 (47.6) 1200 (47.6) basic dry weight kg (lb) 735 (1620) 796 (1755) performance data (industrial applications) net rated power (cont.) at 2200 rpm kw (hp) 127 (170) 160 (215) net peak torque(cont.) at 1200 rpm n?m (lb-ft) 758 (559) 967 (713) net rated power (intermit.) at 2200 rpm kw (hp) 149 (200) 168 (225) net peak (intermit) at 1200 rpm n?m (lb-ft) 891 (656) 1012 (747) low idle speed rpm 850 850 fast idle speed rpm 2300 2300 performance data (generator applications) net rated power (prime) at 1800 rpm kw (hp) 142 (190) 168 (225) net rated power (standby) at 1800 rpm kw (hp) 157 (211) 187 (250) net rated power (prime) at 1500 rpm kw (hp) 119 (160) 142 (190) net rated power (standby) at 1500 rpm kw (hp) 130 (175) 157 (210) low idle speed rpm 850 850 fast idle speed rpm 1900/1600 1900/1600 lubrication system oil pressure at rated rpm kpa (psi) 345 (50) 345 (50) oil pressure at low idle kpa (psi) 210 (30) 210 (30) in-crankcase oil temp at rated rpm °c (°f) 115°c (240°f) 115°c (240°f) cooling system (liquid, pressurized with centrifugal pump) recommended pressure cap kpa (psi) 69 (10) 69 (10) coolant temperature operating range °c (°f) 82°-94°c (180°-202f°) 82°-94°c (180°-202f°) coolant flow (industrial) l/min (gal/min) 330 (87) 330 (87) coolant flow (generator) at 1800 rpm l/min (gal/min) 270 (71) 270 (71) at 1500 rpm l/min (gal/min) 210 (55) 210 (55) engine operation system ctm86 (20mar01) 06-200-1 powertech? 8.1 l diesel engines — base engine 032001 pn=431 continued on next page repair&general oem specifications rg,rg34710,4095 –19–01jan96–2/2 item unit of measure 6081tf 6081af hot cylinder compression pressure with injection kpa (psi) 2380-2790 (345-405) 2380-2790 (345-405) nozzles removed valve clearance (cold) intake mm (in.) 0.46 (0.018) 0.46 (0.018) exhaust mm (in.) 0.71 (0.028) 0.71 (0.028) fuel system nozzle opening pressure kpa (psi) 29000 (4200) 29000 (4200) new nozzle opening pressure kpa (psi) 26200 (3800) 26200 (3800) used (min.) injection pump timing timing lines aligned with flywheel at tdc 06 200 2 ctm86 (20mar01) 06-200-2 powertech? 8.1 l diesel engines — base engine 032001 pn=432 repair&general oem specifications 06 200 3 dpsg,ouod007,3504 –19–28nov00–1/2 general oem engine specifications— continued note: for john deere vehicle engines, see machine technical manual. item unit of measure 6081hf001 engine s.n. 6081hf070 engine s.n. ( —199,999) (200,000— ) general data engine type —— in-line, 4 cycle diesel in-line, 4 cycle diesel aspiration —— turbocharged&turbocharged and air-to-air after cooled air-to-air after cooled number of cylinders —— 6 6 bore mm (in.) 116 (4.56) 116 (4.56) stroke mm (in.) 129 (5.06) 129 (5.06) displacement l (cu in.) 8.1 (496) 8.1 (496) combustion system —— direct injection direct injection compression ratio —— 15.7:1 15.7:1 physical dimensions: width mm (in.) 597 (23.5) 597 (23.5) height mm (in.) 1152 (45.3) 1152 (45.3) length mm (in.) 1200 (47.6) 1200 (47.6) basic dry weight kg (lb) 776 (1710) 776 (1710) performance data (industrial applications) net rated power (cont.) at 2200 rpm kw (hp) 190 (255) 206 (276) net peak torque(cont.) at 1200 rpm n?m (lb-ft) 1184 (873) 928 (1259) net rated power (intermit.) at 2200 rpm kw (hp) 224 (300) 242 (325) net peak (intermit) at 1200 rpm n?m (lb-ft) 1393 (1027) 1280 (944) low idle speed rpm 850 850 fast idle speed rpm 2300 2300 performance data (generator applications) net rated power (prime) at 1800 rpm kw (hp) 218 (292) 308 (413) net rated power (standby) at 1800 rpm kw (hp) 240 (322) 345 (462) net rated power (prime) at 1500 rpm kw (hp) 182 (244) 220 (295) net rated power (standby) at 1500 rpm kw (hp) 200 (268) 259 (347) low idle speed rpm 850 850 fast idle speed rpm 1900/1600 1900/1600 lubrication system oil pressure at rated rpm kpa (psi) 345 (50) 345 (50) oil pressure at low idle kpa (psi) 210 (30) 210 (30) in-crankcase oil temp at rated rpm °c (°f) 115°c (240°f) 115°c (239°f) cooling system (liquid, pressurized with centrifugal pump) recommended pressure cap kpa (psi) 69 (10) 69 (10) coolant temperature operating range °c (°f) 82°-94°c (180°-202f°) 82°-94°c (180°-202f°) coolant flow (industrial) l/min (gal/min) 330 (87) 330 (87) coolant flow (generator) at 1800 rpm l/min (gal/min) 270 (71) 270 (71) at 1500 rpm l/min (gal/min) 210 (55) 210 (55) ctm86平顶山约翰迪尔4045柴油机机油冷却器RE56690批发,中卫强鹿缸套R530609批发价,澳门半岛约翰迪尔6090柴油机密封圈修理包信息,武汉约翰迪尔进气门RE518080厂家批发,齐齐哈尔JohnDeere水温传感器el52222供应商,保定约翰迪尔联合收割机发动机涡轮增压器多少钱,九龙强鹿柴油机3029连杆铜套哪家买,鄂尔多斯强鹿RE507799连杆批发,上饶约翰迪尔发电机维修保养配件耗材服务信息,济宁连杆螺丝强鹿4045柴油机的价格,固原约翰迪尔发动机凸轮轴批发商,伊犁JOHNDEERE充电机RE506196哪家买,河南强鹿3029TF120发动机配件厂家价格,沧州约翰迪尔强鹿排气门R520224价格行情,海东强鹿柴油机曲轴厂家批发,福州约翰迪尔6081柴油机气门锁夹供应商,山南约翰迪尔柴油发电机组单体泵多少钱, (20mar01) 06-200-3 powertech? 8.1 l diesel engines — base engine 032001 pn=433 continued on next page repair&general oem specifications dpsg,ouod007,3504 –19–28nov00–2/2 item unit of measure 6081hf001 engine s.n. 6081hf070 engine s.n. ( —199,999) (200,000— ) engine operation system hot cylinder compression pressure with injectors kpa 2380-2790 (345-405) 2380-2790 (345-405) removed valve clearance (cold) intake mm (in.) 0.46 (0.018) 0.36 (0.014) exhaust mm (in.) 0.71 (0.028) 0.56 (0.022) fuel system injector opening pressure kpa (psi) 29000 (4200) ecu programed new injector opening pressure kpa (psi) 26200 (3800) ecu programed used (min.) injection pump timing s.n. ( —199,999) timing lines aligned with flywheel at tdc injection pump timing s.n. (200,000— ) timing pin inserted with flywheel at tdc 06 200 4 ctm86 (20mar01) 06-200-4 powertech? 8.1 l diesel engines — base engine 032001 pn=434 repair&general oem specifications 06 200 5 dx,torq1 –19–01oct99–1/1 unified inch bolt&cap screw torque values torq1a –un–27sep99 top, sae grade&head markings; bottom, sae grade&nut markings grade 1 (no mark) grade 2a (no mark) grade 5, 5.1/5.2 grade 8/8.2 size lubricatedb dryc lubricatedb dryc lubricatedb dryc lubricatedb dryc n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) 1/4 3.8 (2.8) 4.7 (3.5) 6 (4.4) 7.5 (5.5) 9.5 (7) 12 (9) 13.5 (10) 17 (12.5) 5/16 7.7 (5.7) 9.8 (7.2) 12 (9) 15.5 (11.5) 19.5 (14.5) 25 (18.5) 28 (20.5) 35 (26) 3/8 13.5 (10) 17.5 (13) 22 (16) 27.5 (20) 35 (26) 44 (32.5) 49 (36) 63 (46) 7/16 22 (16) 28 (20.5) 35 (26) 44 (32.5) 56 (41) 70 (52) 80 (59) 100 (74) 1/2 34 (25) 42 (31) 53 (39) 67 (49) 85 (63) 110 (80) 120 (88) 155 (115) 9/16 48 (35.5) 60 (45) 76 (56) 95 (70) 125 (92) 155 (115) 175 (130) 220 (165) 5/8 67 (49) 85 (63) 105 (77) 135 (100) 170 (125) 215 (160) 240 (175) 305 (225) 3/4 120 (88) 150 (110) 190 (140) 240 (175) 300 (220) 380 (280) 425 (315) 540 (400) 7/8 190 (140) 240 (175) 190 (140) 240 (175) 490 (360) 615 (455) 690 (510) 870 (640) 1 285 (210) 360 (265) 285 (210) 360 (265) 730 (540) 920 (680) 1030 (760) 1300 (960) 1-1/8 400 (300) 510 (375) 400 (300) 510 (375) 910 (670) 1150 (850) 1450 (1075) 1850 (1350) 1-1/4 570 (420) 725 (535) 570 (420) 725 (535) 1280 (945) 1630 (1200) 2050 (1500) 2600 (1920) 1-3/8 750 (550) 950 (700) 750 (550) 950 (700) 1700 (1250) 2140 (1580) 2700 (2000) 3400 (2500) 1-1/2 990 (730) 1250 (930) 990 (730) 1250 (930) 2250 (1650) 2850 (2100) 3600 (2650) 4550 (3350) a grade 2 applies for hex cap screws (not hex bolts) up to 6 in. (152 mm) long. grade 1 applies for hex cap screws over 6 in. (152 mm) long, and for all other types of bolts&screws of any length. b "lubricated" means coated with a lubricant such as engine oil,/fasteners with phosphate&oil coatings. c "dry" means plain/zinc plated without any lubrication. do not use these values if a different torque value/tightening make sure fastener threads are clean&that you properly start procedure is given for a specific application. torque values listed are thread engagement. this will prevent them from failing when for general use only. check tightness of fasteners periodically. tightening. shear bolts are designed to fail under predetermined loads. always tighten plastic insert/crimped steel-type lock nuts to approximately replace shear bolts with identical grade. 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. tighten toothed/serrated-type lock nuts to the full torque value. fasteners should be replaced with the same/higher grade. if higher grade fasteners are used, these should only be tightened to the strength of the original. ctm86 (20mar01) 06-200-5 powertech? 8.1 l diesel engines — base engine 032001 pn=435 repair&general oem specifications 06 200 6 dx,torq2 –19–01oct99–1/1 metric bolt&cap screw torque values torq2 –un–07sep99 top, property class&head markings; bottom, property class&nut markings class 4.8 class 8.8/9.8 class 10.9 class 12.9 size lubricateda dryb lubricateda dryb lubricateda dryb lubricateda dryb n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) n?m(lb-ft) m6 4.7 (3.5) 6 (4.4) 9 (6.6) 11.5 (8.5) 13 (9.5) 16.5 (12.2) 15.5 (11.5) 19.5 (14.5) m8 11.5 (8.5) 14.5 (10.7) 22 (16) 28 (20.5) 32 (23.5) 40 (29.5) 37 (27.5) 47 (35) m10 23 (17) 29 (21) 43 (32) 55 (40) 63 (46) 80 (59) 75 (55) 95 (70) m12 40 (29.5) 50 (37) 75 (55) 95 (70) 110 (80) 140 (105) 130 (95) 165 (120) m14 63 (46) 80 (59) 120 (88) 150 (110) 175 (130) 220 (165) 205 (150) 260 (190) m16 100 (74) 125 (92) 190 (140) 240 (175) 275 (200) 350 (255) 320 (235) 400 (300) m18 135 (100) 170 (125) 265 (195) 330 (245) 375 (275) 475 (350) 440 (325) 560 (410) m20 190 (140) 245 (180) 375 (275) 475 (350) 530 (390) 675 (500) 625 (460) 790 (580) m22 265 (195) 330 (245) 510 (375) 650 (480) 725 (535) 920 (680) 850 (625) 1080 (800) m24 330 (245) 425 (315) 650 (480) 820 (600) 920 (680) 1150 (850) 1080 (800) 1350 (1000) m27 490 (360) 625 (460) 950 (700) 1200 (885) 1350 (1000) 1700 (1250) 1580 (1160) 2000 (1475) m30 660 (490) 850 (625) 1290 (950) 1630 (1200) 1850 (1350) 2300 (1700) 2140 (1580) 2700 (2000) m33 900 (665) 1150 (850) 1750 (1300) 2200 (1625) 2500 (1850) 3150 (2325) 2900 (2150) 3700 (2730) m36 1150 (850) 1450 (1075) 2250 (1650) 2850 (2100) 3200 (2350) 4050 (3000) 3750 (2770) 4750 (3500) a "lubricated" means coated with a lubricant such as engine oil,/fasteners with phosphate&oil coatings. b "dry" means plain/zinc plated without any lubrication. do not use these values if a different torque value/tightening make sure fastener threads are clean&that you properly start procedure is given for a specific application. torque values listed are thread engagement. this will prevent them from failing when for general use only. check tightness of fasteners periodically. tightening. shear bolts are designed to fail under predetermined loads. always tighten plastic insert/crimped steel-type lock nuts to approximately replace shear bolts with identical property class. 50 percent of the dry torque shown in the chart, applied to the nut, not to the bolt head. tighten toothed/serrated-type lock nuts to the full torque value. fasteners should be replaced with the same/higher property class. if higher property class fasteners are used, these should only be tightened to the strength of the original. ctm86 (20mar01) 06-200-6 powertech? 8.1 l diesel engines — base engine 032001 pn=436 repair&general oem specifications 06 200 7 dpsg,ouo1004,834 –19–13dec00–1/3 group 020 — cylinder head&valves s. n. 河池强鹿柴油机凸轮轴瓦厂家供应,珠海强鹿柴油机活塞销R502755代理,香港岛约翰迪尔曲轴瓦RE65165厂家供货,怒江约翰迪尔6068柴油机水泵盖代理商,兰州约翰迪尔6081柴油机气门座圈厂家批发,那曲约翰迪尔发动机泵芯多少钱,太原约翰迪尔6090柴油机前油封诚信推荐,德州约翰迪尔联合收割机发动机凸轮轴公司,鹤壁约翰迪尔挺柱铜R110126的价格,邯郸约翰迪尔进气门R97490找哪家,白城强鹿3029柴油机止推轴承价格行情,金华约翰迪尔RE38850衬垫套一级代理,台湾约翰迪尔挖掘机出油阀供货商,铜陵强鹿3029柴油机R98062进气门供货商,( —199,999) repair specifications item measurement specification intake valve clearance checking clearance 0.41—0.51 mm (rocker arm-to-valve tip with (0.016—0.020 in.) engine cold) exhaust valve clearance checking clearance 0.66—0.76 mm (rocker arm-to-valve tip with (0.026—0.030 in.) engine cold) valve adjusting screw lock nut torque 27 n?m (20 lb-ft) intake valve clearance adjustment clearance 0.46 mm (0.018 in.) (rocker arm-to-valve tip with engine cold) exhaust valve clearance adjustment clearance 0.71 mm (0.028 in.) (rocker arm-to-valve tip with engine cold) rocker arm cover-to-cylinder head torque 8 n?m (6 lb-ft) (72 lb-in.) cap screws intake valve lift 13.53—13.71 mm (0.533—0.540 in.) at 0.00 mm (in.) wear tolerance 12.65 mm (0.498 in.) at 0.00mm (in.) clearance exhaust valve lift 14.52—14.70 mm (0.572—0.579 in.) at 0.00 mm (in.) wear tolerance 13.64 mm (0.537 in.) at 0.00mm (in.) clearance rocker arm assembly i.d. 19.07—19.10 mm (0.7507—0.7520 in.) shaft o.d. 19.01—19.05 mm (0.7484—0.7500 in.) exhaust valve recess 1.19—1.70 mm (0.047—0.067 in.) below cylinder head maximum recess 2.46 mm (0.097 in.) below cylinder head ctm86 (20mar01) 06-200-7 powertech? 8.1 l diesel engines — base engine 032001 pn=437 continued on next page repair&general oem specifications 06 200 8 dpsg,ouo1004,834 –19–13dec00–2/3 item measurement specification intake valve recess 3.35—3.86 mm (0.132—0.152 in.) below cylinder head maximum recess 4.62 mm (0.182 in.) below cylinder head intake valve spring height 38.1 mm (1.50 in.)@810—880 n (182—198 lb-force) with valve open height 52.5 mm (2.07 in.)@345—399 n (78—90 lb-force) with valve closed exhaust valve spring height 38.5 mm (1.52 in.)@797—867 n (179—195 lb-force) with valve open height 54.5 mm (2.15 in.)@284—338 n (64—76 lb-force) with valve closed intake valve stem od 9.461—9.487 mm (0.3725—0.3735 in.) exhaust valve stem od 9.436—9.462 mm (0.3715—0.3725 in.) intake valve head od 50.87—51.13 mm (2.002—2.012 in.) exhaust valve head od 46.87—47.13 mm (1.845—1.856 in.) valve face runout 0.05 mm (0.002 in.) maximum permissible valve face (intake&exhaust) angle 29.25° ± 0.25° cylinder head plugs torque 60 n?m (44 lb-ft) cylinder head maximum acceptable out-of-flat 0.08 mm (0.003 in.) over entire length/width straightness per any 305 mm (12 within 0.025 mm (0.001 in.) in.) length cylinder head thickness 155.45—155.71 mm (6.120—6.130 in.) wear limit 154.69 mm (6.09 in.) combustion face surface 1.5—2.8 micrometers finish (surface mill only to aa (60—110 micro-in.) finish) maximum wave depth 0.012 mm (0.0005 in.) resurfacing head maximum material removal 0.762 mm (0.0300 in.) ctm86 (20mar01) 06-200-8 powertech? 8.1 l diesel engines — base engine 032001 pn=438 continued on next page repair&general oem specifications 06 200 9 dpsg,ouo1004,834 –19–13dec00–3/3 item measurement specification valve guide id 9.51—9.54 mm (0.3745—0.3755 in.) in new head new guide-to-exhaust valve stem clearance 0.051—0.102 mm (0.002—0.004 in.) new guide-to-intake valve stem clearance 0.025—0.076 mm (0.001—0.003 in.) valve seat angle 30° ± 0.50° maximum runout 0.051 mm (0.0020 in.) exhaust valve seat width 2.0—3.8 mm (0.079—0.150 in.) intake valve seat width 1.4—3.8 (0.055—0.150 in.) valve seat grinding angle 30° ± 0.50° exhaust width 2.0—3.8 mm (0.079—0.150 in.) intake width 1.4—3.8 mm (0.055—0.150 in.) maximum seat runout 0.051 mm (0.0020 in.) oversize inserts width 0.25 mm (0.010 in.) liner height above block 0.051—0.127 mm (0.002—0.005 in.) above block cylinder head flanged-head initial torque 80 n?m (60 lb-ft) “special” cap screws (no washers) cylinder head flanged-head final torque see torque-to-yield procedure in “special” cap screws (no this group for final torque washers) specifications&sequence rocker arm shaft clamps torque 75 n?m (55 lb-ft) intake manifold-to-cylinder head torque 47 n?m (35 lb-ft) exhaust manifold-to-cylinder head torque 47 n?m (35 lb-ft) turbocharger cap screws torque 24 n?m (18 lb-ft) turbocharger oil return torque 27 n?m (20 lb-ft) pipe-to-turbocharger cap screws cylinders (no. 1 is front of engine) firing order 1-5-3-6-2-4 ctm86 (20mar01) 06-200-9 powertech? 8.1 l diesel engines — base engine 032001 pn=439 repair&general oem specifications 06 200 10 rg41165,0000018 –19–18oct00–1/4 group 021 — cylinder head&valves s. n. (200,000— ) repair specifications item measurement specification intake valve clearance checking clearance 0.30—0.41 mm (rocker arm-to-valve tip with (0.012—0.016 in.) engine cold) exhaust valve clearance checking clearance 0.51—0.61 mm (rocker arm-to-valve tip with (0.020—0.024 in.) engine cold) rocker arm cover-to-carrier cap torque 8 n?m (5.9 lb-ft) screws intake valve clearance checking clearance 0.30—0.41 mm (rocker arm-to-valve tip with (0.012—0.016 in.) engine cold) exhaust valve clearance checking clearance 0.51—0.61 mm (rocker arm-to-valve tip with (0.020—0.024 in.) engine cold) valve adjusting screw lock nut torque 27 n?m (20 lb-ft) carrier-to-cylinder head cap screw torque 8 n?m (5.9 lb-ft) solenoid wire retaining nuts torque 1.75 n?m (1.29 lb-ft) rocker arm cover cap screws KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE47431 FUEL LINE 1 X NO. 6

2 RE47430 FUEL LINE 1 X NO. 5

3 RE47429 FUEL LINE 1 X NO. 4

4 R120185 BOLT 5 X

R58186 CLAMP 10 X

R120181 STRAP 5 X

R120182 STRAP 5 X

5 RE47428 FUEL LINE 1 X NO. 3

6 RE502930 FUEL LINE 1 X NO. 2

7 RE502929 FUEL LINE 1 X NO. 1

8 R120186 BOLT 2 X

R71212 CLAMP 1 X

R120183 STRAP 1 X

R120184 STRAP 1 X

R59297 HALF CLAMP 2 X

9 R71212 CLAMP 1 X

R59297 HALF CLAMP 2 X

R74030 CLAMP 1 X

R74804 CLAMP 1 X

R120186 BOLT 2 X

R120183 STRAP 1 X

R120184 STRAP 1 X

10 R120185 BOLT 1 X

R59297 HALF CLAMP 2 X

R120183 STRAP 2 X

11 RE55662 ABSORBER 1 X

12 24H1884 WASHER 1 X 13/32" X 13/16" X 0.120"

13 19M7166 CAP SCREW 1 X M10 X 20

14 RE61593 INJECTION NOZZLE 6 X (A) (ROBERT BOSCH)

15 R84472 WASHER 6 X 7.360 X 18.160 X 2 MM (0.290" X 0.715"

X 0.079")

16 R504057 O-RING 6 087550- X

17 RE501970 ADAPTER 1 X

18 R51937 TUBE NUT 1 X

19 AR85519 PLUG 1 X

20 RE500803 FUEL LINE 1 X

21 R79604 TUBE NUT 1 X

(A) 1 ORANGE DOT

1 POINT ORANGE

1 ORANGEFARBENER PUNKT

1 PUNTO ARANCIONE

1 PUNTO ANARANJADO

1 ORANGEFAERGAD PUNKT

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R60277 SNAP RING 1 X X

2 R375R O-RING 1 X X

3 R60279 NUT 1 X X

4 R60278 SNAP RING 1 X X

5 .. NOZZLE HOLDER 1 X X (SUB RE64184)

6 R83720 WASHER 1 X X 1.02 MM (.0402")

R83721 WASHER 1 X X 1.08 MM (.0425")

R83722 WASHER 1 X X 1.12 MM (.0441")

R83723 WASHER 1 X X 1.18 MM (.0465")

R83724 WASHER 1 X X 1.22 MM (.0480")

R83725 WASHER 1 X X 1.28 MM (.0504")

R83726 WASHER 1 X X 1.30 MM (.0512")

R83727 WASHER 1 X X 1.38 MM (.0543")

R83728 WASHER 1 X X 1.42 MM (.0559")

R83729 WASHER 1 X X 1.48 MM (.0583")

R83730 WASHER 1 X X 1.50 MM (.0591")

R83731 WASHER 1 X X 1.58 MM (.0622")

R83732 WASHER 1 X X 1.60 MM (.0630")

R83733 WASHER 1 X X 1.68 MM (.0661")

R83734 WASHER 1 X X 1.70 MM (.0669")

R83735 WASHER 1 X X 1.78 MM (.0701")

R83736 WASHER 1 X X 1.82 MM (.0717")

R83737 WASHER 1 X X 1.88 MM (.0740")

R83738 WASHER 1 X X 1.90 MM (.0748")

R83739 WASHER 1 X X 1.98 MM (.0780")

7 R108699 SPRING 1 X X

8 R108700 SEAT 1 X X

9 R108701 PLATE 1 X X

10 RE48360 NOZZLE 1 X (7 X .255)

RE42306 INJECTION NOZZLE 1 X (7 X .240)

11 R127176 NUT 1 X X

12 R84472 WASHER 1 X X

13 RE64184 INJECTION NOZZLE 6 X (A) (ROBERT BOSCH)

RE61593 INJECTION NOZZLE 6 X (B) (ROBERT BOSCH)

(A) (2) PINK DOTS (B) (1) ORANGE DOT

(2) POINT ROSE (1) POINT ORANGE

(2) ROSAFARBENER PUNKT (1) ORANGEFARBENER PUNKT

(2) PUNTO ROSA (1) PUNTO ARANCIONE

(2) PUNTO ROSADA (1) PUNTO ANARANJADO

(2) ROSAFAERGAD PUNKT (1) ORANGEFAERGAD PUNKT