Perkins 6.3544发动机预防性维修维护保养时间表

Perkins 6.3544发动机预防性维护时间表

Preventive maintenance periods

预防维修周期

These preventive maintenance periods apply to average conditions of operation. Check the periods given by

这些预防性维护周期适用于平均操作条件。检查给定的时间

the manufacturer of the equipment in which the engine is installed. If necessary, use the shorter periods. When

安装Perkins 6.3544发动机的设备的制造商。如果有必要,使用较短的时间。什么时候

the operation of the engine must conform to the local regulations these periods and procedures may need to

Perkins 6.3544发动机的运行必须符合当地法规,这些周期和程序可能需要

be adapted to ensure correct operation of the engine.

为确保Perkins 6.3544发动机的正确运行。

Caution: For short distance operation with frequent stops, the hours of operation are more important than the

警告:对于短距离的操作,频繁的停止,时间的操作是更重要的比

distance.

距离。

It is good preventive maintenance to check for leakage and loose fasteners at each service.

检查每一个服务的泄漏和松动的紧固件,这是一个很好的预防性维护。

These maintenance periods apply only to engines that are operated with fuel and lubricating oil which conform

这些维修周期只适用于燃料和润滑油的Perkins 6.3544发动机,其符合

to the specifications given in this handbook.

在本手册中给出的规格。

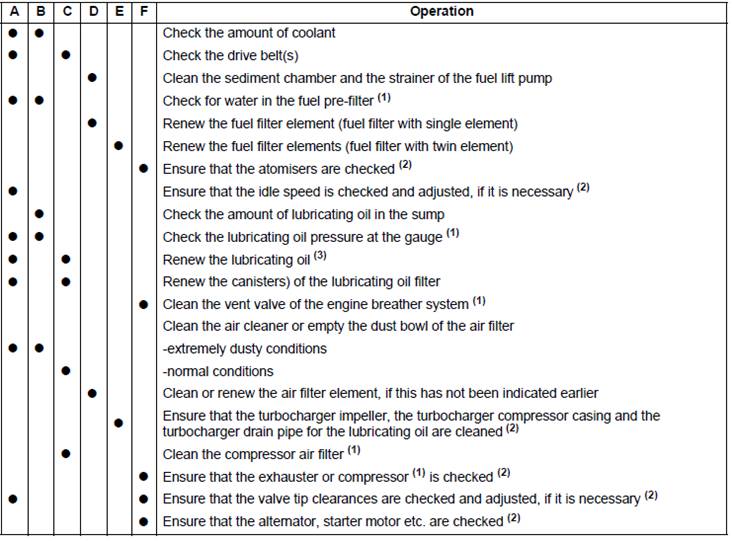

Schedules

时间表

The schedules which follow must be applied at the interval (kilometres, miles, hours or months) which occurs

在发生的时间间隔(公里,英里,小时或几个月)必须使用的时间表

first.

第一.

(1) If there is one fitted.

(1)如有一个装。

(2) By a person who has had the correct training.

(2)由有正确训练的人。

(3) The oil change interval will change with the sulphur content of the fuel (see the table below and "Fuel specification" on page 43).

(3)燃油变化间隔将随燃料的硫含量而变化(见表43)及“燃料规格”页)。

The interval to change the canister of the lubricating oil filter is not affected.

更换机油滤清器罐的间隔不受影响。

A First service at 800/1600 km (500/1000 miles), 25/50 hours

第一服务为800 / 1600公里(1000 / 500英里),25 / 50小时

B Every day or every 8 hours

每一天或每8小时

C Every 7500 km (5000 miles), 250 hours or 4 months

每7500公里(5000英里),250小时或4个月

D Every 15000 km (10000 miles), 500 hours or 12 months

每15000公里(10000英里),500小时或12个月

E Every 30000 km (20000 miles), 1000 hours

每30000公里(20000英里),1000小时

F Every 90000 km (60000 miles), 2500 hours

每90000公里(60000英里),2500小时

(1) If there is one fitted.

(1)如有一个装。

(2) By a person who has had the correct training.

(2)由有正确训练的人。

(3) The oil change interval will change with the sulphur content of the fuel (see the table below and "Fuel specification" on page 43).

(3)燃油变化间隔将随燃料的硫含量而变化(见表43)及“燃料规格”页)。

The interval to change the canister of the lubricating oil filter is not affected.

更换机油滤清器罐的间隔不受影响。

How to drain the cooling system

如何排水冷却系统

Caution: Do not drain the coolant while the engine is still hot and the system is under pressure because

警告:当Perkins 6.3544发动机仍热,系统处于压力之下时,不要排空冷却液

dangerous coolant can be discharged.

危险的冷却液可以排出。

1 Ensure that the machine is on level ground.

1确保机器在平地上。

2 Remove the filler cap of the cooling system.

2拆下冷却系统的填充盖。

3 Remove the drain plug from either side of the cylinder block (A) in order to drain the engine.

3卸下气缸体的任何一方的泄放塞(一)以便排出Perkins 6.3544发动机。

Note: Ensure that the drain hole is not restricted.

注:确保排水孔不受限制。

4 Open the tap or remove the drain plug at the bottom of the radiator in order to drain the radiator. If the radiator

4打开水龙头,或在散热器底部清除排水沟,以便排出散热器。如果散热器

does not have a tap or drain plug, disconnect the hose at the bottom of the radiator.

无水龙头或排水插头,断开散热器底部的软管。

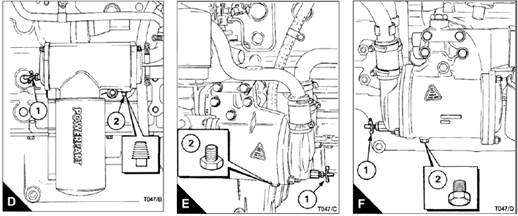

5 If a lubricating oil cooler is fitted, open the drain tap or remove the drain plug (B1 or C1/D1/E1/F1) in order

5如果润滑油冷却器安装,打开排水阀门或拆下螺塞(B1、C1、D1、E1、F1)为

to drain the coolant from the oil cooler.

从机油冷却器中排出冷却液。

6 If a water to air charge cooler is fitted, the vent plug (G1) must be removed when the cooling system is

6如果水增压空气冷却器安装、排气塞(G1)必须清除冷却系统时

drained or filled.

排水或填充。

7 If necessary, flush the system with clean water.

7如有必要,用清水冲洗系统。

8 Fit the drain plugs in the cylinder block. Fit the filler cap. Close the radiator tap or connect the radiator hose.

8配合气缸体中的漏极塞。安装填料盖。关闭散热器龙头或连接散热器软管。

Close the drain tap or fit the drain plug of the oil cooler. If a water to air charge cooler is fitted, fit the vent plug.

关闭泄油器或安装机油冷却器的泄放塞。如果一个水对空气中的装冷却器装,安装排气孔。

9 If frost may occur while the engine is drained, disconnect a pipe connection at the oil cooler and put 250 ml

9如果Perkins 6.3544发动机排水,在油冷却器上断开管道连接,并将250毫升

(1/2 pint) of POWERPART antifreeze into the oil cooler. Connect the coolant pipe.

(1 / 2品脱)取得的防冻液到机油冷却器。连接冷却液管。

How to check the drive belt(s)

如何检查传动带(的)

Renew a belt if it is worn or damaged. If twin belts are fitted, they must be renewed together.

如果损坏或损坏,则更换皮带。如果双皮带装,他们必须重新在一起。

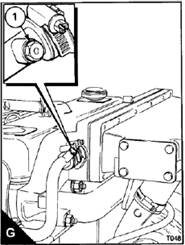

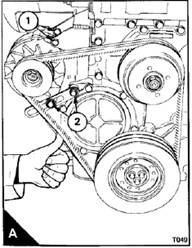

To check the belt tension, press down the belt with the thumb at the centre of the longest free length and check

要检查皮带的张力,按最长的长度和检查中心的拇指向下按压皮带

the deflection (A). With moderate thumb pressure - 45N (10 Ibf) 4,5 kgf - the correct deflection of the belt is

挠度(一)。中度拇指压45N(10 IBF)4,5 KGF的皮带挠度是正确的

10 mm (3/8 in).

10毫米(8 / 3英寸)。

If twin belts are fitted, check/adjust the tension on the tighter belt.

如果有双皮带,检查/调整拉紧皮带上的张力。

How to adjust the belt tension

如何调整皮带张力

1 Loosen the pivot fasteners (A1) of the alternator and the adjustment link fasteners (A2).

1松开轴紧固件(A1)的发电机和调节连接紧固件(A2)。

2 Change the position of the alternator to give the correct tension. Tighten the pivot fasteners of the alternator

2改变交流发电机的位置,使其正确的拉力。拧紧交流发电机的枢轴紧固件

and the adjustment link fasteners. Where there are two pivot fasteners, tighten the front fastener and then the

和调整连接紧固件。在那里有2个枢轴紧固件,拧紧前紧固件,然后

rear fastener.

后扣。

3 Check the belt tension again to ensure that it is still correct.

3检查皮带张紧力,确保其正确。

Note: If a new belt is fitted, the belt tension must be checked again after the first 25 hours of operation.

注:如果一个新的皮带,皮带张力,必须再次检查后,第一个25小时的操作。

How to clean the gauze strainer of the fuel lift pump

如何清洁的燃油泵纱布过滤器

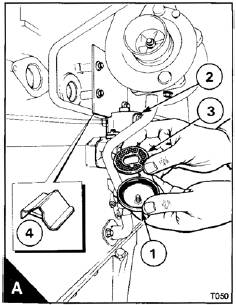

1 Remove the cover and joint (A1) from the top of the fuel lift pump (A2) and remove the gauze strainer (A3).

1拆下盖和关节(A1)从燃油泵上(A2)和取出纱布过滤器(A3)。

On engine types TU and TX, it will be necessary to remove the small heat shield (A4) which is fitted above the

Perkins 6.3544发动机类型图和TX,要除去小的热屏蔽(A4),上面安装了

pump.

泵。

2 Carefully wash all the sediment from the lift pump body.

2仔细清洗电梯泵体的所有沉积物。

3 Clean the gauze strainer, joint and cover.

3清洁纱布过滤,关节和盖。

4 Assemble the lift pump. Use a good joint and ensure that the lift pump body and the cover are fitted together

4组装起升泵。使用一个良好的接头,确保电梯泵体和盖安装在一起

correctly because leakage at this point will let air into the fuel system. On engine types TU and TX, fit the heat

正确,因为在这一点上的泄漏将使空气进入燃油系统。Perkins 6.3544发动机类型图和TX,适合热

shield.

盾。

5 Eliminate the air from the fuel system through the filter vent point, see "How to eliminate air from the fuel

5消除燃油系统中的空气通过过滤器的排气口,看“如何消除燃油的空气

system" on page 33.

系统“在33页。

Fuel pre-filter

燃油预滤器

This will normally be fitted between the fuel tank and the engine. Check the filter bowl for water at regular

这通常是安装在燃油箱和Perkins 6.3544发动机之间。定期检查滤水器碗

intervals and drain as necessary, see "How to drain the cooling system" on page 27.

每隔一段时间,如有必要,见“如何排水冷却系统”页27。

How to renew the filter element(s) of the fuel filter

燃油滤清器滤芯的更换

Caution: It is important that only the genuine Perkins fuel filter element is used. The use of a wrong element

警告:这是非常重要的,只有真正的帕金斯燃料过滤元件。使用一个错误的元素

can damage the fuel injection pump.

损坏燃油喷射泵。

The filter can have one or two elements. When twin elements are fitted, both of the elements must be renewed

过滤器可以有一个或2个元素。当两个元素的装配,这两个元素必须重新

at the same time.

在同一时间。

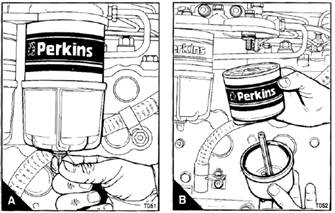

1 Clean the outside surfaces of the fuel filter assembly. If a drain tap is fitted to the filter bowl, drain the fuel

1清洁燃油滤清器总成的外表面。如果一个排水龙头安装在滤碗中,排水

from the filter (A).

从过滤器(一)。

2 Hold the bottom cover of the filter element and release the setscrew which is fitted through the filter head

2保持滤芯的底盖和释放固定螺丝装在滤头

above the centre of each element.

以上各要素的中心。

3 Lower the bottom cover of the filter (B).

3较低的过滤器的底部盖(乙)。

4 Remove the element and discard it.

4删除元素并丢弃它。

5 Clean the inside surfaces of the filter head and of the cover.

5清洗过滤器头部和盖的内表面。

6 Renew the seals and lightly lubricate them with clean fuel.

6更换密封件,并用清洁燃料轻轻润滑它们。

7 Put the bottom cover under the new element and hold it squarely to the filter head. Ensure that the element

7把底部盖在新的元素,并保持它正视的过滤器头。确保元素

is fitted in the centre against the joint in the filter head. With the assembly in this position, engage and tighten

在过滤器头上安装在中心。在这一位置,接合和紧固组件

the setscrew.

固定螺丝。

8 Eliminate the air from the fuel filter, see "How to eliminate air from the fuel system" on page 33.

8消除燃油滤清器的空气,从33页上看“如何消除燃油系统中的空气”。