Perkins3012燃油喷射泵及调速器的维修保养技术参数资料

Perkins3012燃油喷射泵及调速器的维修保养技术参数资料

Fuel injection pump and governor

英国帕金斯燃油喷射泵及调速器

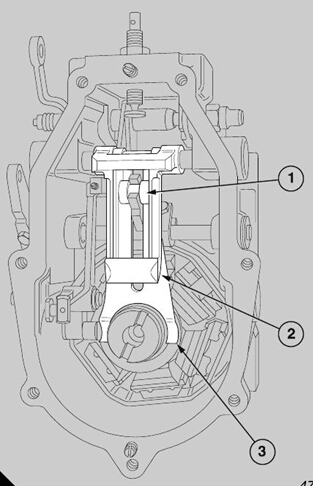

Before the fuel

injection pump can be lifted from the

在燃油喷射泵可以从

engine, various other

components must be removed.

发动机,各种其他部件必须拆除。

Obtain a suitable bar, which

will fit in the holes in the

获得一个合适的酒吧,这将适合在洞里

fan belt pulley to turn the

c rankshaft when necessary,

风扇皮带轮转动曲轴时必要的,

and proceed as

follows:

并进行如下:

1 Disconnect and remove the 12 high-pressure

fuel

1断开并拆下12高压燃油

pipes for the fuel injectors.

燃油喷射管。

2 Disconnect

and remove the linkage for the speed

2断开并拆下速度的连接

control, the linkage for

the stop control, and the

控制,停止控制的联动

assembly of the engine stop

solenoid.

发动机停止电磁线圈的装配。

3 Disconnect and remove the assembly of the

levers

3断开并拆下杠杆的装配

and the cross shaft.

和十字轴。

4 Disconnect the

leak-off pipe from between ’B’ bank

4断开'乙'银行之间的泄漏管

and the connection

block and the pipes for the spill

和泄漏的连接块和管道

fuel from the low-pressure

relief valves and the gallery

燃油从低压溢流阀和画廊

of the fuel injection

pump.

燃油喷射泵。

5 Disconnect the low-pressure pipes from the

lift

5断开电梯的低压管道

pump and the fuel filters.

泵和燃油过滤器。

6 Disconnect the

delivery pipe and the drain pipe for

6断开输送管和排水管

the lubric ating oil from

the cambox and the housing of

润滑油的流动从三角座和壳体

the governor.

州长。

7

Remove the guard for the assembly of the

auxiliary

7拆下辅助装配的防护

drive.

驱动。

8 Turn the engine until the timing

marks are aligned.

8转动发动机,直到计时标记对齐。

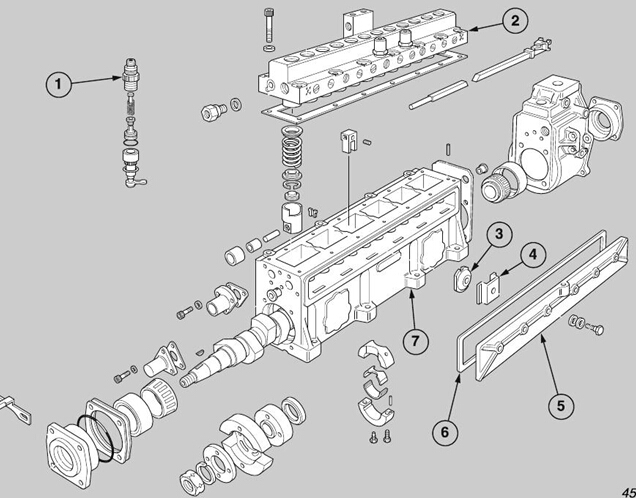

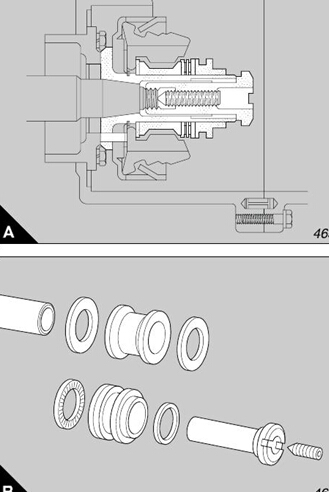

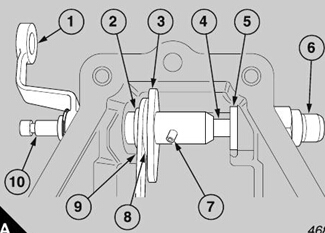

Remove the two long nuts (A2) from the

assembly of

拆下两长螺母(A2)从总成

the flange (A4) of the auxiliary drive shaft and

the

法兰(A4)的辅助传动轴和

pack of eight spring steel plates (A3) which

are

八弹簧钢板组(A3),

nearest to the timing case, and withdraw the two

bolts

最近的时间的情况下,撤回的两根螺栓

(A1) of the coupling toward the timing

case.

(A1)的耦合对正时箱。

9 Release and remove the eight bolts, the

plain

9松开并拆下八个螺栓,平

washers and locking washers, which retain the

fuel

保留燃油的垫圈和锁止垫圈

injection pump.

喷射泵。

10 Connect the lift adaptor, 21825 876, to two of the

holders of the delivery valves. Use a hoist to lift

carefully the fuel injection pump, which is complete

with the governor and the spring steel plates of the

drive coupling, away from the crankcase and on to a

clean bench.

Caution: The clamp ring of the adjustable coupling is

retained securely by special bolts. For early engines,

cap screws are used and for new engines a type of

bolt is used which has a washer integral with the

head.

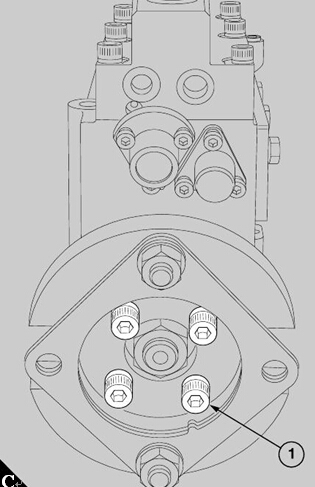

11 Loosen and remove the four special bolts from the

clamp ring of the adjustable coupling; remove the

clamp ring, and the assembly of the flywheel and the

drive coupling.

12 Use the hoist to lift the assembly of the fuel

injection pump away from the bench. Hold the

assembly over a suitable container, remove the drain

plug from the end face of the governor and tilt the

assembly to allow the lubricating oil to drain from the

cambox and the governor housing.

To fit

Obtain a suitable bar, which will fit in the holes in the

fan belt pulley to turn the crankshaft when necessary,

and fit the fuel injection pump/governor assembly to

the engine as follows:

1 Fit the two off-centre control rods to the speed

control lever and the stop control lever of the

governor.

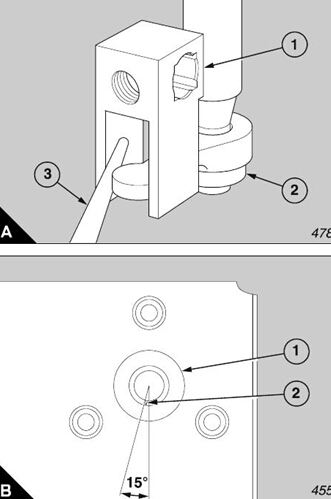

Caution: When the drive coupling for the fuel

injection pump is as sembled, the special plain

washers are fitted only on each side of each pack of

eight spring s teel plates as shown (A). All the nuts are

fitted only on the inner sides of the assembly of the

drive coupling; the four long nuts retain only the drive

shaft for the fuel injection pump.

2 During the assembly of an engine, it is relevant to

assemble first on a bench, the drive shaft for the fuel

injection pump, one pack of eight spring steel plates

and the flywheel, as shown (A). Ensure that the four

bolts, the special plain washers and the nuts are fitted

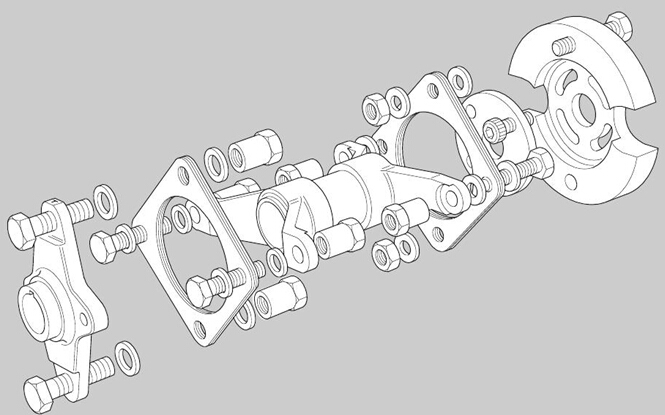

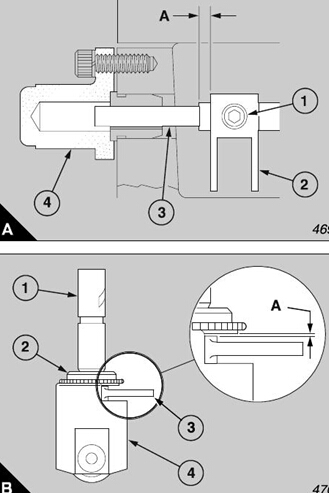

3 Tighten to 120 Nm (88 lbf ft) the two long nuts and

the two standard nuts. Align the assembly with the

hub of the fuel injection pump and fit the clamp ring

with the four special bolts. Insert the special bolts into

the hub until they are finger-tight. Turn the assembly

of the drive coupling until the timing mark on the hub

is aligned with the timing pointer (A).

4 Assemble, on the bench, the flange of the drive

coupling and the second pack of eight spring steel

plates with two bolts, four special washers and two

standard nuts. Use the other two bolts, with four

special washers and two long nuts, to align the other

two holes of each spring steel plate.

5 Ensure that the four bolts, the special washers and

the nuts are fitted correctly, generally as shown (page

167/A). Tighten the two standard nuts to a torque of

120 Nm (88 lbf ft).

6 Check that the taper of the auxiliary drive shaft is

clean, and press the ’Woodruff’ key into its keyway.

Fit the flange for the drive coupling onto the s haft,

followed by the plain washer and the nut. Tighten the

nut to the relevant torque load:

18 mm nut ................. 200 Nm (148 lbf ft).

22 mm nut ................. 300 Nm (220 lbf ft).

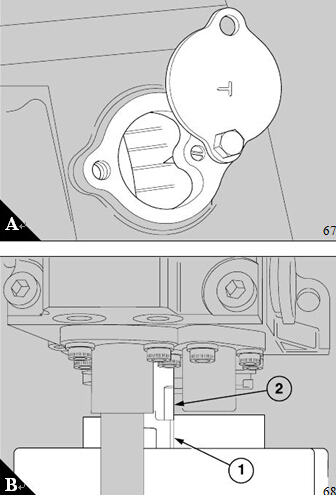

7 If necessary, turn the crankshaft until the arm,

which is marked ’T’ (on the flange of the drive

coupling) is above the shaft and is vertical. Remove

the two long nuts from the bolts which pass through

the second pack of eight spring steel plates but retain

the two special washers on the bolts.

8 Use the lift adaptor, 21825 876, and a suitable hoist

to lower carefully the assembly of the fuel injection

pump and the drive coupling into the ’V’ of the

crankcase. Move carefully the assembly toward the

auxiliary drive shaft and enter the protrusions of the

two bolts into their respective holes in the drive shaft

of the fuel injection pump. Ensure that the two special

washers remain on the bolts and fit the long nuts.

Hold the head of each bolt with a ring spanner and

tighten each nut to 120 Nm (88 lbf ft).

9 Insert the eight bolts, with the plain washers, which

retain the fuel injection pump, through the bolt holes

in the base of the fuel injection pump. Tighten each

bolt to 41 Nm (30 lbf ft).

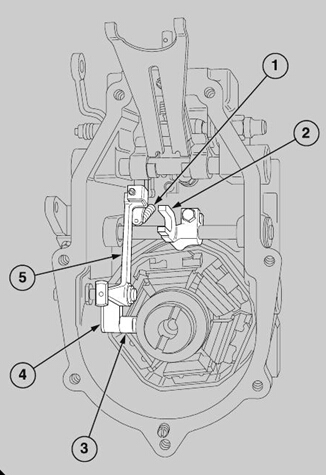

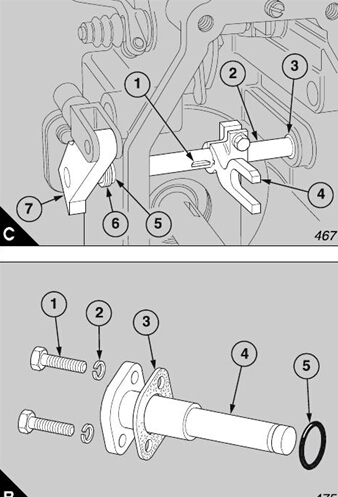

10 Loosen one or two turns the four cap screws (C1)

or, if relevant, the four special bolts in the clamp ring,

and turn the crankshaft until the timing mark on the

flywheel is in alignment with the pointer (A).

11 Turn the hub of the fuel injection pump by hand in

the normal direction of its rotation (anti-clockwise as

seen from the driven end) until the timing mark on the

hub (B1) passes the timing pointer (B2). Turn slowly

backward the hub until the timing mark and the timing

pointer are correctly aligned. For early engines

tighten the four cap screws (C1) to 69 Nm (51 lbf ft).

For new engines tighten the four special bolts to 46

Nm (34 lbf ft).

Note: The clamp ring of the adjustable coupling is

retained securely by special bolts. For early engines,

cap screws (C1) are used and for new engines a

special bolt is used which has a washer integral with

the head.

12 Turn backward a quarter of a turn (90°) the

crankshaft (anti-clockwise as seen from the front of

the engine). Then turn slowly forward the cranks haft

until the timing marks on the flywheel are aligned

correctly . Check the timing mark of the fuel injection

pump. This, also, should be aligned correctly. If

neces sary, use the same procedure to adjust the

timing again.

13 Ensure that the two 'O' rings are fitted into the

connection on the fuel injection pump which returns

the lubricating oil from the driven end of the cambox.

Slide the pipe on to the connection and engage the

lower end of the pipe in the boss on the cover plate.

Tighten securely the union nut.

14 Fit the guard for the aux iliary drive assembly.

15 Fit the lubricating oil drain pipe between the union

on the servo-valve cover and the boss on the cover

plate in the crankcase ’V’. Inspect the seal in the

cover plate for damage and renew it if necessary. If

the seal is renewed, ensure that the correct type of

seal for your engine is fitted. Apply a small amount of

clean engine oil to the seal, fit the banjo bolt, complete

with a new sealing washer, through the connection at

the top of the pipe and tighten it securely .

Caution: During this operation, hold the banjo

connection to prevent movement of the pipe while the

bolt is tightened. If the pipe moves, it can damage the

seal against its bore in the cover plate.

16 Connect the low-pressure pipes to the lift pump

and the fuel filters.

17 Connect the leak-off pipe to ’B’ bank from the

connection block and the pipes for the spill fuel to the

low-pressure relief valves and the gallery of the fuel

injection pump.

18 Fit and connect the assembly of the levers and the

cross shaft.

19 Fit and connect the linkage for the speed control,

the linkage for the stop control, and the assembly of

the engine stop solenoid. To adjust the linkage of the

stop solenoid refer to operation 23-21.

20 Fit and connect the 12 high-pressure fuel pipes for

the fuel injectors. Tighten the nuts of the high

pressure fuel pipes to 45 Nm (33 lbf ft).

Caution: Ensure that the fuel injection pump is

primed with clean engine oil, of the correct

specification, before the engine is first started.

帕金斯3012柴油泵拆卸和组装

To dismantle and to assemble

拆卸和组装

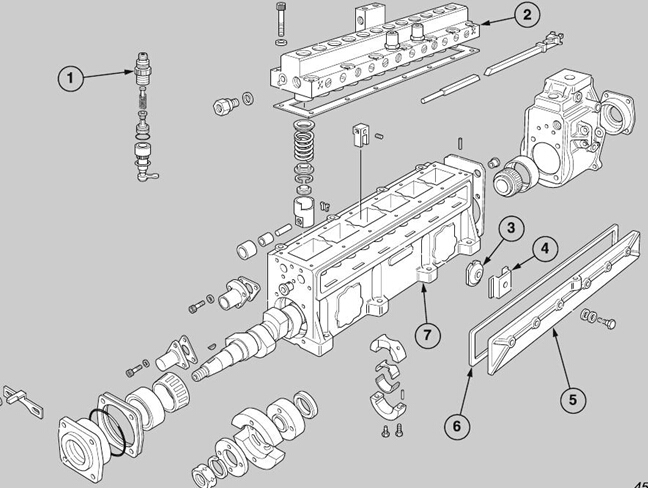

3 Remove the six clips (A4) which

retain the

3删除六剪辑(A4)保留

threaded plates (A3) and turn the threaded plates

90°

螺纹板(A3)和螺纹板90°

to release them from the cambox

(A7).

释放他们从三角座(A7)。

4 Use the spanner OD 5192 to loosen each of

the

4用扳手松开的OD 5192

holders of the delivery valves (A1) one or two

turns.

对阀门的持有人(A1)的一个或两个转。

Do not remove the holders during this

operation.

请勿在本手术中移除支架。

5 Release, evenly and gradually, the cap

screws

5释放,均匀地,逐渐地,帽螺丝

which hold together the cambox and the body of

the

这抱在一起的三角座的身体

pump (A2). Press lightly downward on the body

while

泵(A2)。在身体上轻轻向下按压

the screws are removed. Do not lift the body of

the

螺钉被拆除。不要提起身体的

pump at this stage.

在这个阶段的泵。

6 Loosen the vice and

put the complete assembly of

6松开副并将其完成装配

the fuel injection pump and the

mounting bracket onto

喷油泵和安装支架上

the bench.

板凳。

7 Move carefully the

assembly of the fuel injection

7小心地移动燃油喷射的装配

Before the fuel injection

pump and the

在喷油泵和

pump onto its side, with the opening downward on

the

泵到它的侧面,随着打开向下的

governor are dismantled, clean thoroughly

the

总督被拆除,彻底清除

outside of the assembly with kerosene and dry

with

外与用煤油组装

compressed air.

压缩空气。

1 Hold securely the mounting

bracket OD 21467 in a

1在一个固定支架上安装21467个固定支架

vice, fit the assembly onto

the bracket and remove the

副,装配到支架上并拆下

lift adapter, 21825

876.

电梯适配器,876 21825。

2 Remove all locking wire from the assembly,

release

2拆下装配中的所有锁丝,松开

the six bolts which retain the inspection cover

(A5)

六螺栓保留检查盖(A5)

and remove the inspection cover and the joint

(A6).

并拆下检查盖和联合(A6)。

bench.

台。

8 Lift carefully the body of the pump

away from the

8小心地抬起泵的身体远离

cambox so that the plungers remain in

their

三角座使柱塞留在他们

9 Withdraw each plunger c omplete with its spring and

the upper and lower spring plates.

Caution: Put each assembly of a plunger in a

separate container as soon as it has been removed.

Mark each container with the number of the element

to ensure that the components of one element do not

become mixed with the components of another

element.

10 Remove each of the already loosened holders

(A1) of the delivery valves (A5) together with the

spring (A2) and the peg (A6). Place each assembly

in its respective container with its relevant plunger

assembly.

11 Remove and discard the special sealing washers

(A4) from the top of eac h valve guide (A3).

12 Withdraw each delivery valve and its relevant

guide from the body of the pump. Put each as sembly

in its respective container.

13 Use a soft faced hammer on the bottom end of

each barrel (B1) to release it from the body of the

pump. Discard the ’O’ rings (B3) and the was hers

(B2) from the seats of the barrels and put the barrels

in their respective containers.

14 In rotation, dip the plungers and the barrels in

clean test oil and assemble each plunger to its

respec tive barrel to prevent damage to the fine

surface finishes. Return each assembly to its

respectiv e container.

Lift out the assembly of each tappet from the cambox

and dismantle as follows:

15 Push out the pin from the tappet guide and

withdraw the roller and the bush.

16 Remove the circlip from the tappet guide and

withdraw the spacer.

17 Put the assembly of each tappet in its respective

18 Slide out, from between the bores of the tappets,

the ’T’ pieces and make a note of the order of their

removal to ensure that they are assembled correctly.

Hold again the assembly of the fuel injection pump

and the mounting bracket in the vice and proceed as

follows:

19 Release the lock nut and loosen fully the s crew of

the maximum fuel stop which is in the top of the

governor housing (A1). Release the seven bolts

which fas ten the end cover of the governor to the

housing; remove the end c over and the joint.

20 Move the end of the variable ramp (A3) upward

and lift out the assembly of the roller for the ramp (A2)

from the control fork (B2) of the speed control.

21 Make a note of the arrangement of the primary

spring (A4) and the variable ramp, to ensure that they

will be assembled correctly, and withdraw the pivot

from the s ide which is opposite to the inspection cover

of the cambox. Remove the primary spring and the

variable ramp.

22 Remove the bolts and the spring washers from the

flange of the pivot and remove the ’E’ type circlip from

the inner end of the pin; remove the shim washer from

behind the circlip.

23 Hold the lever of the servo-valve (B4), the shims

and the assembly of the connection type lever (B5)

and withdraw the pivot with the joint. Remove the

shims.

24 Move both levers to the left and forward to release

the slipper pin (B3) from the groove in the thrust plate,

which is a component in the assembly of the governor

hub. Withdraw the slipper pin and separate the two

levers.

25 Remove the two extension type springs (B1) from

the control rod and the connection ty pe lever. Lift out

the connection type lever.

26 Use a suitable tool to hold the hub of the fuel

injection pump, and loosen the locking screw in the

centre of the nut on the hub of the governor.

27 Use the key OD 21465 to release and remove the

nut of the hub, together with the spacers.

28 Use the extractor OD 21466 to withdraw the

complete hub of the governor (A) from the taper on

the end of the camshaft; separate the components

(B).

29 Use a sharp device to remove the ’Spirolox’ ring

from its groove in the governor hub, and lift away the

plate type retainer and the governor weight holder.

Press out the six rubber blocks from the slots in the

governor weight holder.

Make a note of the position of the speed control lever,

relative to the control fork for the roller, to give

assistance when the unit is assembled and proceed

as follows:

30 Loosen the clamp setscrews and withdraw the

speed control lever (C7), which has an integral stop

on new engines. Remove also the separate stop of

early engines.

31 Loosen the clamp setscrew on the control fork for

the roller (C4) and slide the control fork for the roller

along the shaft (C2) to enable the ’Woodruff’ key (C1)

to be removed.

32 Remove the ’E’ type c irclip, the plain washer, the

special spring washer (C6) and the inner plain washer

(C5) from the speed control shaft at the end for the

lever. Withdraw the shaft and lift out the control fork

for the roller.

33 Remove and discard the ’O’ ring type seals, and

the retainer rings, from the bushes (C3) of the speed

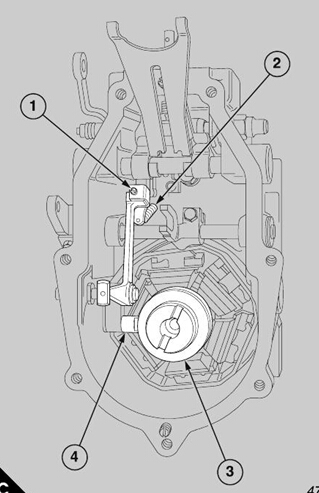

34 Remove the ’Groverlok’ pin (A7) which

secures

“‘groverlok引脚34删除,secures(A7)

the assembly of the lever for

’maximum stop’ (A3) to

该组件的最大杠杆是停止(A3)

the shaft of the excess fuel device

(A4). Remove the

过量的燃料装置的轴(A4号)。删除的

rubber shroud from around the excess

fuel button

橡胶罩来自过剩的燃料。

(A10) and remove also the stop control lever

(A1).

(10)和删除的控制杆也停止了(A1)。

35 Release the cap (A6) at the opposite end of

the

释放帽(35)是在对面的尽头)

shaft and remove the spring and the

washer.

轴、弹簧和垫圈删除。

36 Remove the retainer ring, the washer and the

’O’

删除的36型聘环,垫圈和“O”的

ring type seal from around the excess fuel

button,

型密封环的过量燃料来自巴顿

slide out the shaft for the excess fuel and remove

the

该轴滑出的燃料和消除过剩的

retainer ring, the assembly of the lever for

’maximum

型聘环,是最大的杠杆总成

stop’, the sealing washer (A8), the assembly of

the

停止,密封垫圈(A8)的,该组件

shaft for the stop control (A9), the thrust washer

(A2)

轴的停止控制(A9),(A2)的推力垫圈

and the bush (A5).

和布什(5)。

To inspect the

servo-valve and the assembly of the

在对伺服阀和inspect汇编的

piston, the cover of

the valve must be removed from

活塞的阀盖,必须删除从

the end cover of the governor.

According to which

端盖的州长。根据这

type of end cover is fitted, proceed as

follows:

端盖是一种基于í,如下:

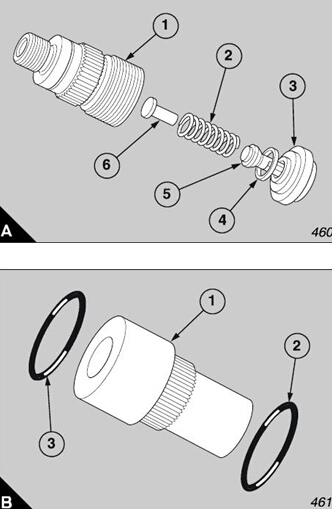

37 If the early type of end cover is fitted, remove

the

37,如果类型是基于早期的端盖,清除

vent plug, and the connection of the inlet for the

oil,

通风插头和连接的入口的油

from the cover of the servo-valve. Remove the

cover

从覆盖的伺服阀。该盖去除

of the servo-valve, discard the joint, and remove

and

的伺服阀,联合和删除和丢弃。

discard the ’O’ ring type seal from the groove in

the

丢弃的O型圈密封在从槽型

cover of the servo-valve. Lift out the assembly of

the

盖的伺服阀。大会的升降机-PSP

servo-valve.

伺服阀。

38 If an altered type of

cover is fitted for the servo-

如果一个覆盖38是基于蚀变类型的伺服

valve, remove the vent

plug and the connection of the

在排气阀,删除和连接的插头

inlet for the oil and push

upward the assembly of the

进口的石油和upward汇编的《推

piston to remove the plug

which is fitted below the

活塞,这是消除基于下面的插头

flange of the cover. Discard the

’O’ ring type seal and

法兰的封面。丢弃的O型圈密封型和

the joint of the

cover.

该接头的盖。

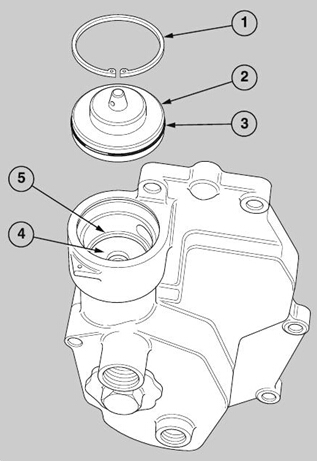

39 If the new type of end cover for the governor

is

如果新的39型端盖是在州长

fitted (page 153/A), remove the circlip which

retains

基于(153页),《circlip retains移除它

the plug in the top of the bore,

withdraw the plug and

《顶级孔插头,插头和退休

remove the ’O’ ring type seal. Remove

the circlip

删除的O型圈密封型。删除的circlip

which retains the internal plug in the

bore of the piston

这retains插头内孔的活塞

and push up the servo-valve and piston

assembly to

推上的伺服阀门和活塞组件。

remove the plug. Discard the ’O’ ring type

seal.

插头删除。丢弃型的O型圈密封。

After the governor has been dismantled, continue

to

州长已经dismantled后,继续

dis mantle the fuel injection pump. Proceed

as

在燃油喷射泵的DIS的地幔。í的

40 Remove the three cap screws and the spring

washers which retain the cover for the control rod to

To assemble

20

the cambox. Remove the cover and the joint.

41 Loosen each of the cap screws which fasten the

control forks to the control rod and slide the control

rod out through the governor housing. Lift out the

control forks as they become free.

42 Fit the anti-rotation tool OD 21468 on the hub at

the drive end of the fuel injection pump and use the

key OD 21465 to release the lock nut which retains

the hub. Use the puller OD 5343 to withdraw the hub

from the taper of the camshaft, and remove the

’Woodruff’ key.

43 Loosen the lock nuts and remove from under the

cambox the screws which retain the two inner

bearings.

44 Remove the four ’Tuflok’ bolts, and the four bolts

with spring washers, which retain the housings of the

front and rear roller bearings to the cambox. Remove

the timing indicator.

45 Use a soft faced hammer to hit lightly the rear end

of the camshaft and loosen the bearing housing from

the front end of the cambox. Withdraw the bearing

housing and remove the shims ; discard the oil s eal

and the ’O’ ring type seal. Hit lightly the front end of

the camshaft to loosen the rear bearing housing and

withdraw the camshaft, with the two assemblies of the

inner bearings, from the cambox

46 Remove the two bolts which retain each of the two

bearing caps, and separate the bearing caps and the

half bearings from the camshaft.

Caution: Each bearing cap is stamped with a

number to ensure its correct relationship when it is

assembled.

47 Use suitable extractors to remov e the inner races

of the bearings from each end of the camshaft and to

withdraw the outer races from the front and the rear

bearing housings. Keep together each inner race and

its relevant outer race as an assembly and put in to

storage.

48 If it is necessary to separate the governor housing

from the cambox, remove from inside the housing the

one bolt which remains. Disc ard the joint.

1 Put a new joint on the cambox face at the end for

the governor. Ensure that the ports which circulate

the oil are not restricted and use the central ’Tuflok’

bolt to c onnect the governor housing to the cambox.

2 Use a hollow drift to fit the inner races of the

bearings to each end of the camshaft.

3 Lubricate lightly the outer races of the bearings and

press them into their respective bearing housings.

4 Fit the rear bearing hous ing to the gov ernor

housing, apply a small amount of Loctite 241 to the

threads of the four bolts which retain the housing and

fit the bolts, with new spring washers, into the bolt

holes. Tighten each bolt to 25,75 Nm (19 lbf ft).

Tighten the ’Tuflok’ bolt to 16 to 20 Nm (12 to 15 lbf ft).

5 Remove the assembly of the cambox from the vice

and put it in an upright position on the governor

housing. Lower carefully the assembly of the

camshaft into its position in the cambox, fit the shims

to the drive end of the cambox and fit temporarily the

bearing housing. Fit the four ’Tuflok’ bolts and tighten

them to 16 to 20 Nm (12 to 15 lbf ft). Fit again the

assembly to the vice.

6 Use a dial test indicator with a magnetic base to

check the end float of the camshaft. The permissible

end float is 0,05 to 0,127 mm (0.002 to 0.005 in). If

necessary, vary the thickness of the shims to adjust

the end float.

The shims which are av ailable for this purpose are

listed below:

Part No. Shim thickness

509582 0,19 mm (0.0076 in)

509583 0,27 mm (0.0108 in)

509584 0,38 mm (0.0148 in)

7 Loosen the four ’Tuflok’ bolts and put the assembly

in an upright position on the governor housing.

Remove the bolts, the bearing housing and the shims.

Withdraw the camshaft.

8 Apply clean engine lubricating oil to the central half

bearings. Fit the as sembly of each bearing onto the

camshaft and ensure that the marks which give the

correct relationship are aligned correctly. Fit the

dowels and the bolts, and tighten the bolts to 6 to 7,5

Nm (4.5 to 5.5 lbf ft).

9 Fit the assembly of the camshaft into the cambox

and align the two inner bearings with the threaded

holes in the base of the cambox. To prevent the

leakage of the lubricating oil from the cambox, apply

’Loctite 242’ to the threads of the two screws which

retain the two inner bearings. Fit the screws, with

their lock nuts, through the base of the cambox, into

the bearing caps. Tighten by hand until the spigot of

each screw is engaged fully in its bearing cap.

Loosen each screw half a turn and tighten the lock

nuts to 16 to 20 Nm (12 to 15 lbf ft). Ensure that the

screws do not turn when they are tightened.

Hold the assembly of the c ambox in the vice and

proceed as follows :

10 Press a new oil seal into the bearing housing with

the lip of the seal toward the centre of the fuel

injection pump. Put the necessary shims over the

spigot of the housing, s pread a small amount of

silicone grease around the spigot and fit a new ’O’ ring

into the groove.

11 Fit the bearing housing to the cambox, align the

bolt holes and fit the four ’Tuflok’ bolts and the timing

indicator. Tighten gradually and evenly the bolts to 16

to 20 Nm (12 to 15 lbf ft).

12 Fit the ’Woodruff’ key into the keyway, slide the

hub onto the taper of the camshaft and fit the spring

washer and nut. Use a suitable tool to hold the hub of

the fuel injection pump and tighten the nut to 150 Nm

(110 lbf ft).

Ensure that all the components of the pump body

have been cleaned thoroughly and proceed as

follows:

13 Dip each component in clean test oil. If they have

been removed, fit the plugs and new sealing washers

at the ends of the gallery. Tighten each plug to 115 to

136 Nm (85 to 100 lbf ft).

14 If the blanking plugs along the gallery have been

removed, dry the threads, apply ’Loctite 241’ to the

thread of each blanking plug, fit new sealing washers

and insert the blanking plugs into the body of the

pump. Tighten each blanking plug to 32,5 to 40,5 Nm

(24 to 30 lbf ft).

15 Fasten temporarily the body of the pump to the

cambox and fit new washers for the seats of the

barrels into each bore in the body. Align the

serrations of each barrel with those in the body and

assemble it to its correct location.

16 Apply some silicone grease to the new ’O’ rings

(page 172/B3) and put one on the top of each barrel.

For each element in rotation, fit the guide for the

delivery valve, the delivery valve and a new special

sealing washer.

17 Fit the springs of the delivery valves, followed by

the pegs which reduce the volume.

18 Apply ’Castrol grease 5903’ to the threads of the

holders of the delivery valves and fit eac h holder into

its respective location. Use the soc ket type spanner

OD 5192 to tighten each holder to 115 to 129 Nm (85

to 95 lbf ft). Remove the assembly of the pump body

from the cambox.

19 Slide the control rod through the bush at the rear

end into the cambox and, at the same time, fit the

control forks onto the rod in the correct s equence.

20 Put the control fork (A2) for no.1 element 3,0 mm

(0.118 in) from the end (dimension A) of the square

section of the rod (A3) and tighten its locking screw

(A1) to 4,75 to 6,0 Nm (3.5 to 4.5 lbf ft).

21 Slide backward the control rod by a small amount

to align the no.1 control fork with the centre of the

bore of its tappet. Align the remainder of the 11

control forks with the bores of their respective tappets

and tighten the locking screws as instructed for no.1

control fork.

22 Fit the end cover (A4) for the control rod. Use a

new gasket and new spring washers and tighten the

three cap screws to 2,70 to 4,0 Nm (2 to 3 lbf ft).

Check that the control rod slides freely in its bushes.

23 Assemble the roller of the tappet, the bush and the

pin into each tappet guide. Insert the tappet spacer

and fit the circlip, with the c onvex side next to the

spacer, to retain the assembly.

24 Check the clearance, dimension ’A’ as shown (B),

between the arm of each plunger (B3) and its

respec tiv e tappet spacer, as given below:

25 Assemble the lower spring plate (B2) to the

plunger (B1) and hold firmly the seat of the lower

spring plate in its position in the body of its relevant

tappet. Use the feeler gauges to check the clearance

between the bottom face of the lower s pring plate and

the shoulder on the arm of the plunger. The

permis sible clearance is from 0,05 to 0,20 mm (0.002

to 0.008 in). If the clearance exceeds these limits, the

lower spring plate must be ex changed for a lower

spring plate with a suitable thickness. Refer to the

end of this section.

Move the mounting bracket of the fuel injection pump

in the vice until the camshaft has an approximately

20° angle of tilt, with the drive end of the camshaft at

the lower position, then proceed as follows:

26 Insert no.1 tappet into its bore in the cambox with

the cut-out in the tappet body toward the control fork.

Fit carefully the ’T’ piece to its position next to the

tappet. The ’T’ piece will be against the s ide of the

tappet, which will reduce the danger that it may fall

into the cambox. Fit the remainder of the tappets and

the ’T’ pieces in the correct sequence.

27 When all the tappets have been fitted into the

cambox, remove the assembly of the fuel injection

pump from the vice and put it on its side with the

opening downward on the bench to enable the body

of the pump to be fitted. Align the control forks with

the assemblies of their respectiv e tappets.

28 Insert the pump plungers into their respective

barrels and fit a lock plate to the pump body to retain

the plungers . Connect a supply of compressed air to

the inlet connection for fuel and close all other

openings in the fuel gallery with temporary blanking

plugs.

29 Check for leakage of air by the complete

immersion of the pump body in a container of c lean

test oil. Ensure that the air pressure does not exceed

345 kN/m (50 lbf/in ) and allow the air to enter the

gallery. Check for the formation of air bubbles. A

small amount of leakage from around the plungers is

acceptable but further leakage must be corrected

before the procedure can continue.

30 When the pressure test is completed, and is

acceptable, remove the assembly from the container

of oil, disconnect the supply of air and remove the

temporary blanking plugs. Allow the surplus oil to

drain from the pump body.

31 Put the pump body on its side with the inlet

connection for fuel at the top. Fit the lower spring

plate to each plunger, the spring which returns the

plunger and the upper spring plate. Insert the

plungers into their respective barrels, with the arms of

the plungers vertically downward.

32 Put a new joint on the top face of the cambox and

fit carefully the pump body . Ensure that the arms of

the plungers engage correctly in their control forks.

Insert four cap screws, with new sealing washers, into

the bolt holes at the corners of the pump body and

tighten securely the cap screws.

|

33 Fit the partial assembly of the fuel injection pump

to a ’Hartridge HA 3000’ test rig, or a similar test rig,

and connect a supply of low-pressure oil to the

adaptor in the inlet of the pump body. Ensure that the

oil pressure does NOT exceed 14 kN/m (2 lbf/in ).

Do not start the flow of the oil at this stage.

34 Remove the holder of the delivery valve, the peg

which reduces the volume, the spring of the delivery

valve and the delivery valve from the no.1 element of

the pump.

35 Use the adaptor 89558/10 and the holder ST 184

to fit the dial test indicator 23764, in the place of the

holder of no.1 delivery valve.

36 Slide the control rod for the fuel to the position of

’maximum fuel’, that is, toward the governor, and turn

the camshaft until the no.1 plunger is at the bottom of

its stroke, that is, with the tappet roller on the back of

the cam.

37 Start the flow of oil to the pump body and check

the flow of oil from the base of the gauge holder. Turn

slowly the camshaft in its normal direction of rotation

until the flow of oil stops; this is known as the point of

’spill cut-off’ and it is also the point at which the no.1

element starts to inject the fuel during the operation of

the engine. Check the timing mark on the hub of the

camshaft, the front edge of the mark should be

aligned with the edge of the indicator plate. If the

point of spill cut-off has been correctly obtained and

the edges are not aligned, a new timing mark should

be made on the hub of the camshaft to align with the

indicator plate.

38 Check the reading on the dial test indicator and

measure the movement of the plunger from the

bottom of its stroke to the point of spill cut-off.

Compare this reading with the correct stroke given in

the test schedule.

39 To adjust the length of the stroke, remove the

assembly of the pump from the test rig and release

the four cap screws which retain the body. Put the

assembly on its side with the opening downward and

withdraw carefully the body of the pump and the

assemblies of the plungers.

40 Withdraw and dismantle the assembly of the no.1

tappet and exchange the spacer for another spacer of

the necessary thickness to give the correct movement

of the plunger.

Caution: Ensure that the original clearance is

maintained between the spacer and the lower s pring

plate. If a thicker spacer is fitted to the assembly of

the tappet, a lower spring plate, which is respectively

thinner, must be fitted. When a thinner spacer is

necessary, a lower spring plate, which is respectively

thicker, must be fitted. A list of the sizes of the

spacers and the spring plates is given at the end of

this section.

41 Fit the pump body to the cambox as already

instructed (see paragraph 32) and install the pump on

the test rig. Check again the movement of the no.1

plunger and, if it is correct, set to zero the degree

plate on the test rig. This setting will give a datum to

check the remainder of the elements.

42 Stop the flow of oil and remove the dial test

indicator, the holder and the adaptor from the no.1

element. Fit again the assembly of the delivery valve.

Use the socket type spanner OD 5192 to tighten the

holder of the delivery valve to 115 to 129 Nm (85 to 95

lbf ft).

43 Remove the components of the delivery valve

from the next element in the injection sequence,

which is no.9 element, and connect a swan neck pipe

to the holder of the delivery valve as shown (A). Start

the flow of oil.

|

44 Turn slowly the camshaft in its normal direc tion of

rotation and check the flow of oil from the swan neck

pipe. When the plunger begins to close the inlet port,

the flow of oil will gradually decrease. Continue to turn

very slowly the camshaft until the flow of oil stops

completely. Check the reading on the degree plate.

If the point of spill cut-off is correct, the degree plate

should indicate 30°. If the reading on the degree plate

is not within 30°± /2°, make a note of the reading to

ensure that the spacer of the tappet can be changed

later. Stop the flow of oil, remove the swan neck pipe

and assemble the components of the delivery valve.

Apply the correct torque to tighten the holder of the

delivery valve.

45 Repeat the procedure for each of the remainder of

the elements, in increments of 30°. Follow the

sequence given below.

Sequence 1 9 4 11 2 7

Degrees 30 60 90 120 150 180

Sequence 6 10 3 8 512

Degrees 210 240 270 300 330 360

46 Disconnect the supply of oil and remove the pump

from the test rig. If the timings for the injec tions of one

or more of the elements of the pump were incorrect,

exchange the spacers and the lower spring plates for

those of the correct thickness, and check again the

pump on the test rig.

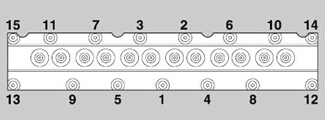

47 Hold in the vice the pump assembly on its

mounting plate and loosen the four cap screws. Insert

the remainder (11) of the cap sc rews, with new

sealing washers, and tighten each cap screw, evenly

and gradually, in the sequence shown (A) to a torque

of 20,3 to 20,4 Nm (15 to 17 lbf ft).

48 Check that all the lower spring plates are fitted

correctly on their tappet as semblies and that the

control rod moves freely.

49 Before the governor is assembled, chec k all the

components for wear or damage, especially the thrust

faces and the bearing surfaces; renew components or

assemblies where necessary.

50 Check the tension of the spring in the servo-valve

assembly and, if necessary, renew it. Dip the

assembly in clean test oil and slide it into the s ervo-

valve piston. Fit the piston into the bore in the cover

of the governor and align the slot in the piston to

receive its guide sc rew.

51 Apply silicone grease to a new ’O’ ring type seal

and fit it into its groove in the servo cover. Assemble

the cover to the bore of the piston as shown (A). If

relevant to the type of cover, fit new joints and sealing

washers. Tighten the vent plug and the inlet

connection for oil to a torque of 27,0 to 34,0 Nm (20.0

to 25.0 lbf ft).

52 Fit a new retainer ring and two new ’O’ ring type

seals to the excess fuel shaft (B4). Lubricate the

shaft, and the bore of the stop control shaft (B9), with

’Rocol ASP’ molybdenum disulphide grease. Slide

the excess fuel shaft through the wall in the side of the

governor housing, with the flat surface face

downward.

53 Fit the thrust washer (B2), the assembly of the

stop control shaft, the sealing washer (B8), the

assembly of the ’maximum stop’ lever (B3) and the

bush (B5) on to the excess fuel shaft. Continue to

slide the shaft through the governor housing and put

the bush in the bore of the housing.

54 Apply ’Loctite 241’ to the thread of the bush, fit a

new washer around the thread of the bush and insert

the spring in the cap. Fit the cap (B6) onto the bush

and tighten the cap to a torque of 20 to 23 Nm (15 to

17 lbf ft).

55 Push the excess fuel shaft fully into its location

and press the ’Groverlok’ pin (B7) into the assembly

of the ’maximum stop’ lever. Fit the stop control lever

(B1) and tighten the bolt which retains the lever to a

torque of 4,5 to 5,5 Nm (3.5 to 4.0 lbf ft). Fit the rubber

shroud over the end of the shaft (B10).

56 Insert two rubber pads into each slot in the base

of the governor weight holder. Put the hub of the

governor on the bench and fit carefully the weight

holder over the hub so that the rubber pads are on

each side of the three drive pegs. Ensure that there

is no distortion of the pads and that they are not

damaged during this operation.

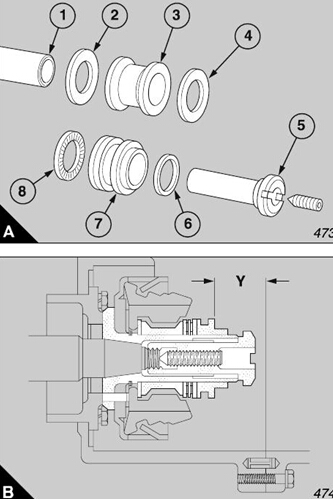

Key to illustration A

1 Circlip

2 Servo-valve cover

3 ’O’ ring

4 Servo-valve guide

5 Circlip

57 Put the plate type retainer over the protrusions of

the pegs and fit the ’Spirolox’ ring into its groove in the

hub body (A1).

58 Fit the six weights into the weight holder of the

governor. Put the 48,3 mm diameter thrust washer

(A2) against the thrust faces of the weights, and the

bobbin type sleeve (A3) against the thrust washer.

59 In sequence, fit the thrust washer(s) (A4), the

needle type thrust bearing (A8), the thrust plate (A7)

and the spacer(s) (A6) onto the hub of the governor

and put the hub assembly on the tapered end of the

camshaft.

60 Hold the camshaft hub with the tool OD 21468 and

fit the nut. Use the tool OD 21465 to tighten the nut to

a torque of 38,0 to 43,5 Nm (28 to 32 lbf ft).

Check that the joint fac e of the governor housing is

clean, ensure that the governor weights are in the

’fully closed’ position and proceed as follows:

61 Use a depth gauge to measure accurately the

distance ’Y’ from the joint face of the housing to the

face of the outer flange of the thrust plate (B). See the

test schedule of the fuel injection pump to chec k the

measurement. If the reading on the depth gauge is

incorrect, the thrust washer(s) may be exchanged for

new washers of the necessary thickness.

62 Apply ’Loctite 241’ to the threads of the locking

screw and fit it into the threaded bore of the hub nut.

Tighten the locking screw to a torque of 20 to 27 Nm

(15 to 20 lbf ft).

63 Press the ’E’ type circlip (A6) into its groove in the

speed control shaft, at the lever end. Fit the outer

washer, the special spring washer and the inner

washer (A5) against the inner face of the ’E’ type

circlip. Fit new retainer rings and new ’O’ ring type

seals into the bushes (A3) which support the shaft

(A2) in the governor housing. Lubricate the bushes

with silicone grease and slide the shaft into the

housing from the side for the lever. Fit the control fork

for the roller (A4) onto the shaft and insert the shaft

through the second bush in the opposite side of the

housing. Fit the plain washer, the special spring

washer and the second ’E’ type circlip to the

protrusion of the shaft.

64 Slide the speed control lever (A7) on to the splined

end of the shaft and tighten the bolt which retains the

lever to a torque of 4,5 to 5,5 Nm (3.5 to 4.0 lbf ft).

65 Press the ’Woodruff’ key (A1) for the control fork

into the shaft and slide the control fork into its location

over the key. The central line through the control fork

must be within 0,25 mm (0.010 in) of the vertic al

central line of the governor housing. When the lever is

positioned correctly, tighten the bolt which retains the

lever to a torque of 4,5 to 5,5 Nm (3.5 to 4.0 lbf ft).

66 Use a small wire hook to connect the two springs

(C2) to the control rod.

67 Fit a new ’O’ ring type seal (B5) and a new joint

(B3) on the pivot ((B4). Ins ert partially the pivot into

the governor housing and fit the thrust washers over

the protrusion of the inner end of the pivot.

68 Fit the slipper pin (C4) into the lever of the servo-

valve and assemble the connection type lever to the

lever of the servo-valve, with the dowel in its correct

location. Fit both levers in the housing, with the

slipper pin engaged in the groove in the thrus t plate

(C3). Press the pivot through the bores of the two

levers, and fit the shim washer and the ’E’ type circlip

over the protrusion of the end of the pivot. Fit the two

bolts (B1), with new spring washers (B2) through the

flange of the pivot and tighten them to a torque of 4,0

to 7,0 Nm (3 to 5 lbf ft). Connect the free ends of the

two springs to the assembly of the connection type

69 Fit a new ’O’ ring type seal to the pivot for the

spring of the governor. Assemble the leaf spring and

the variable ramp in the governor housing. Insert the

pivot into its bore in the side of the housing for the

control lever and through the eyes of the assembly of

the leaf spring and the ramp. Push the pivot fully into

its correct location until the ends are aligned precisely

with the faces of the governor housing.

At this stage of the operation, set the control rod of the

fuel injection pump as follows:

70 Remove the three cap screws which retain the

end cover of the control rod to the cambox. Remove

the cover and the gasket.

71 Loosen the adjustment screw (page 184/C1) in

the top of the connection type lev er of the governor.

Hold the weights of the governor in the ’fully open’

position and turn the adjustment screw until the

square section of the control rod for fuel is just in

contact with the face of the bush at the drive end of

the cambox.

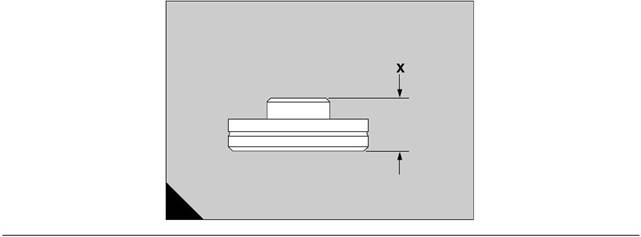

72 Measure accurately the protrusion of the round

section of the control rod from the outer face of the

cambox, (A, dimension X) and make a note of the

measurement. Turn anti-clockwise the adjustment

screw to reduce the measurement by 0,1 to 0,5 mm

(0.004 to 0.020 in) (A, dimension Y). Tighten

temporarily the lock nut of the adjustment screw and

check again the protrusion. If the protrusion is

correct, tighten fully the lock nut.

73 Hold the weights of the governor in the ’fully

closed’ position, press the excess fuel device and

check the movement of the control rod. The

movement must not be less than 24 mm (0.94 in).

74 Fit the joint and the end cover for the control rod

and tighten the cap screws to a torque of 2,70 to 4,0

Nm (2.0 to 3.0 lbf ft).

When the movement of the control rod is set correctly,

continue to assemble the governor as follows:

75 Put the convex bottom end of the primary spring

(B3) against the face of the thrust plate and turn the

end of the variable ramp (B2) upward. Put the

assembly of the roller for the ramp (B1) in the fork of

the control lever, with the large diameter of the roller

against the outer face of the primary spring, and lower

the variable ramp.

76 Apply grease to both sides of a new joint for the

cover and put the joint on the housing. Remove the

large plug from the end cover of the governor and fit

carefully the cover to the housing. Ensure that the

connection type lever and the lever for the servo-

valve are engaged correctly in the recesses in the

piston of the servo-valve and in the servo-valve. Fit

the seven bolts, with new spring washers, which

retain the end c over and tighten each bolt to a torque

of 5,5 to 8,0 Nm (4.0 to 6.0 lbf ft).

Caution: Before the large plug is fitted, check again

that the assembly of the lev ers is engaged correctly in

the servo-valve and its piston and that all the moving

parts of the governor have a full and free range of

movement. A failure to do these checks could cause

the engine to be badly damaged by excessive speed.

77 Fit the large plug, with a new joint, and tighten it to

a torque of 38,0 to 41,0 Nm (28.0 to 30.0 lbf ft). Use

locking wire to ensure that the plug is retained

清洗燃油喷射泵的所有部件

clean test oil and dry them with compressed air.

清洁试验油,并用压缩空气干燥。

Check each part for wear and damage in accordance

检查各部分的磨损和损坏情况

with the instructions given below:

下面给出的说明:

1 Inspect the plunger and the barrel for marks or

1检查活塞和桶的痕迹或

damage. Very small scratches are acceptable but

损伤。非常小的划痕是可以接受的,但

deep scratches, and roughness on the upper edge of

深的划痕,和粗糙度的上边缘

the groove for spill fuel, indicate excessive wear. In

泄漏燃料的槽,表明过度磨损。在

this situation, it is recommended that all the elements

这种情况,建议所有的元素

of the fuel injection pump are renewed.

燃油喷射泵的更新。

2 If the components have very small scratches,

2如果组件有很小的划痕,

assemble each element in clean test oil. Hold

组装各单元在清洁测试油。持有

vertically the assembly and turn the plunger in both

垂直的组件,并把柱塞在这两个

directions . The assembly is acceptable if the plunger

方向。该组件是可以接受的,如果柱塞

rotates freely without interference and if, when the

自由旋转而不受干扰,当

plunger is released, its weight causes it to fall slowly.

柱塞被释放,它的重量使它慢慢地下降。

3 Inspect the spring, which returns the plunger, for

3检查弹簧,该弹簧返回柱塞,用于

cracks and corrosion and check the length of the

裂纹和腐蚀,检查长度

spring against a new spring. If it is defective, fit a new

春天对一个新的春天。如果是有缺陷的,适合一个新的

set of springs.

弹簧组。

4 Check the seats of the barrels in the pump for

4检查泵中的桶的位置

erosion or other damage. If necessary, correct the

侵蚀或其他损坏。如果需要,正确

seats with the tool ST 146. Remove only the

座位与工具146。只删除

minimum amount of metal to res tore the faces of the

金属的最小量的撕裂的脸的

seats.

座位。

5 Check the assemblies of the delivery valve for

5检查阀门的总成

erosion and deposits which may be caused by the

可能引起的侵蚀和沉积

contamination of the fuel oil; renew the assemblies if

燃油的污染;如果更换组件,如果

necessary.

必要的。

6 Check the camshaft for damage or erosion.

6检查凸轮轴的损坏或侵蚀。

Excessive wear on the cams will affect the

凸轮上的过度磨损会影响到

characteristics of the injection of the fuel.

燃料的注入特性。

7 Check the camshaft bearings for wear or signs that

7检查凸轮轴轴承的磨损或标志

they have been affected by excessive temperature.

他们受到过多的温度影响。

Check that the races of the bearings are not worn and

检查轴承的种族不磨损和

that there is no erosion. If there are signs of wear or

有没有侵蚀。如果有磨损的迹象或

8 Inspect the walls of the tappets for wear, and check

the bores of the cambox, especially around the ’T’

pieces. Renew all worn components.

9 Check the assemblies of the rollers for wear. If

necessary, renew the rollers, the pins and the bushes.

10 Use the relevant feeler gauges (A3) to check the

clearance between each control fork (A1) and the arm

of its respective plunger (A2). The permissible limits

are 0,01 to 0,20 mm (0.0004 to 0.008 in). If a gap is

excessive, renew the element and/or the relevant

control fork.

11 Fit temporarily a new control rod to check the

bushes of the control rod for wear and ovality. If the

clearance is excessive, withdraw the control rod, drive

the locking pin into the rear bush and carefully remove

both bushes.

12 Fit a new bush for the rear end, ensure that the

holes for the locking pin in the cambox and the bush

are aligned correctly, then insert the locking pin into

its position through the top face of the cambox.

Ensure that the pin is engaged in the bush but does

not extend into the bore of the bush.

13 Press in a new bush (B1) at the front end. Ensure

that the ’V’ groove (B2) on the front face of the bush

is 15 degrees to either side of B.D.C.

14 Check that the control rod moves freely in the new

bushes and then withdraw the rod.

英国帕金斯柴油发动机喷油泵校准

1 The accurate measurement and adjustment of the

fuel, which is supplied by each element of the pump,

can be done only with the use of special equipment

and by the personnel who have had the correct

training. Unless the equipment and the personnel are

available, the fuel injection pump must be returned to

the manufacturer.

2 Fit the assembly of the fuel injection pump onto the

test rig and ensure that there is a minimum clearance

of 0,5 mm (0.02 in) between the fuel injection pump

and the coupling of the test rig.

3 Connect the delivery pipe, for the lubricating oil,

and the drain pipe to the fuel injection pump and the

governor. Connect the delivery pipe for the test oil to

the gallery of the fuel injection pump. Connect the

drain pipes to the outlets of the low-pressure relief

valves.

4 Start the flow of test oil and loosen the unions at the

relief valves. When the leakage of oil is shown to be

free from bubbles, tighten securely the unions.

5 Check the distance (dimension ’A’) between the

end face of the fork (A2) for no.1 element and the

square shoulder of the control rod (A3). If necessary,

loosen the locking screw (A1) which retains the

control fork and slide the control fork along the rod to

give a reading of 0,30 mm (0.012 in) at dimension ’A’.

Tighten the locking screw to a torque of 4,75 to 6,0

Nm (3.5 to 4.5 lbf ft).

6 Hold the lever for speed control in the ’max imum

fuel’ position and the lever for the stop control in the

’run’ position. Start the test rig and drive the fuel

injection pump at a speed according to the

specification in the test schedule. Make a note of the

quantity of test oil which is discharged from the no.1

element for the number of the strokes given in the

schedule.

7 Adjust the stop for ’maximum fuel’ until the quantity

of test oil from the no.1 element is c orrect. Tighten

lightly the lock nut.

8 Check, two or three times, the quantity of the test

oil from the no.1 element. If the quantity is constant,

tighten securely the lock nut.

9 Check the quantity of the tes t oil which is

discharged from the remainder of the elements (11)

and adjust as necessary the forks. To increase the

output from an element, slide its fork a very small

distance toward the governor. To dec rease the

output, slide its fork toward the drive end of the pump.

Tighten the lock nut of the fork to its correct torque

after each adjustment.

10 Remove the assembly of the fuel injection pump

from the test rig and fit, into the recesses in the

cambox, the threaded plates for the bolts which retain

the inspection cover. Hold the threaded plates in their

locations with the clips.

11 Apply silicone grease to new ’O’ ring type seals

and fit them around each of the bolts which retain the

inspection cover.

12 Fit a new seal to the inspection cover and put the

inspection cover on the cambox. Insert the bolts, with

plain washers, through the inspection cover into the

threaded plates and tighten them gradually and

evenly to a torque of 8,0 to 9,5 Nm (6.0 to 7.0 lbf ft).

燃油泵调试perkins

To test the fuel injection pump

Conditions for the test rig

The test oil MUST conform to ISO 4113Test schedule

Test rig:

Hartridge 1100 test rig

Fuel injectors for the test:

|

|

The test oil and the filters should be renewed every

six months or after 50 pumps have been tested; at the

interval whic h occurs first.

High-pressure pipes

These must be of steel tube which is solid drawn, 8.0

mm outside dia. x 3.0 mm bore and 760 mm long.

The minimum radius of a bend should be 50 mm.

Pressure of the test oil

The fuel injection pump does not have an integral lift

pump and the test rig must supply the test oil. During

the calibration, the pressure of the test oil must be

kept at 207 to 241 kN/m (30 to 35 lbf/in ).

Lubricating oil

The lubricating oil specification must be OMD 80, and

it must flow to the inlet of the servo-valve at a pressure

of 207 kN/m (30 lbf/in ). The temperature of the

lubricating oil must be controlled between 30 and

50°C.

The oil is returned from the outlet of the servo-valve.

This is a s tandard banjo connection and it must be

fitted face downward. Where relevant for early

engines, a separate drain pipe should be fitted to the

end cover of the governor to keep the level of the

lubricating oil at the approximate centre of the

camshaft.

Fill the cambox to the level of the outlet of the servo-

valve.

Maximum permissible difference

The explanation of the words 'Maximum permissible

difference' in the test schedule is 'The maximum

permis sible difference between the highest and the

lowest readings, after calibration, within the

tolerances given for the quantity of the test oil which

is discharged'.

These are matched for the flow and are supplied in

sets (C.A.V. part no. 6731502) with nozzles (C.A.V.

part no. BDN8S2P). They are designed only for the

purpose of the tests and have an opening pressure of

175 atmospheres. They are NOT interchangeable

with the fuel injectors which are fitted to the 3012/

CV12 engine and which operate at 240 atmospheres.

When an order is given for these injectors, give also

the type and the serial number of the test rig.

Pump specification

Type: SPE1212MX130

Rotation: Anti-clockwise from the drive end. Firing

order: 7, 6, 10, 3, 8, 5, 12, 1, 9, 4, 11 and 2.

Governor

Type: GCSVMX400-750S9

Governor weights: 'Y' dimension - 26 to 26,7 mm

(1.02 to 1.05 in)

Procedure

1 Set the end of the adjustment screw for the ramp to

6,90 to 7,00 mm (0.272 to 0.276 in) from the face

which is machined on the end cover of the governor.

2 Adjust both adjustment screws for the stops until

they are aligned with the bracket of the governor

housing to ensure that there is full movement of the

stops.

3 Set no.7 tappet at the drive end to 4,90 to 5,10 mm

(0.193 to 0.201 in), from the bottom of its stroke, to

close the inlet port.

4 Set the remainder of the elements to within ± 0,50

mm (0.020 in) of no.7 element, by the use of the

relevant spacers.

5 Fit the correct spring plates to give each plunger a

vertical end float of 0,05 to 0,20 mm (0.002 to 0.008

Calibration

6 Run the test rig to drive the fuel injection pump at a

speed of 750 rev/min. Adjust the stop for maximum

fuel to discharge 30,8 to 31,0 cc for 100 strokes, from

the no.1 element. Adjust the remainder of the forks to

give a similar quantity of test oil from the remainder of

the elements.

7 Run the pump at 1200 rev/min and check that a

movement of 1,0 mm (0.040 in) of the control rod can

stop the flow of oil from all the elements.

Caution: When a data plate is fitted to the pump, the

stop for the maximum fuel must be adjusted to the

figure given on the data plate after the calibration. If

a data plate is not fitted, the nominal setting for the

maximum fuel is the same as the setting for the

calibration.

Idle speed

8 Run the fuel injection pump at 400 rev/min.

The average of the discharged test oil from each

element should be 10,0 cc for 200 strokes.

Excess fuel

9 Put the control rod in the ’excess fuel’ position, and

run the pump at 100 rev/min. The average of the

discharged test oil from each element should be a

minimum amount of 33,0 cc for 100 strokes. The

’maximum permissible difference’ mus t not exceed

7,0 cc. Check the stop controls.

10 Put the control rod in the ’excess fuel’ position and

ensure that the inlet port closes at a minimum of 3°

later than at the 'setting' position.

Test of governor

11 Adjust the stop for 'maximum speed' until the flow

of fuel is stopped at 810 rev/min. Check again the

adjustment to ensure that the speed remains at 810

rev/min.

12 Check that the control rod starts to move at

speeds between 760 and 790 rev/min.

The adjustment screw for the ramp and the

adjustment screw for the 'maximum speed' s top may

have to be reset to obtain the speeds given above.

Check again the discharged test oil for the idle speed

and reset if necessary .

13 Check that the flow of test oil stops at 880 rev/min

when the supply of lubricating oil to the governor is

14 Put the control rod in the 'maximum fuel' position

and set no.7 element at the point when the inlet port

is just closed. Set the timing pointer to the mark on

the hub of the fuel injection pump and tighten securely

Sizes of spacers (A) available for the tappets

Sizes of spacers (A) available for the tappets

Part Number Dimension ’X’

509459 5,65 to 5,70 mm (0.222 to 0.224 in)

509460 5,75 to 5,80 mm (0.226 to 0.228 in)

509461 5,85 to 5,90 mm (0.230 to 0.232 in)

509462 5,95 to 6,00 mm (0.234 to 0.236 in)

509463 6,05 to 6,10 mm (0.238 to 0.240 in)

509464 6,15 to 6,20 mm (0.242 to 0.244 in)

509465 6,25 to 6,30 mm (0.246 to 0.248 in)

509466 6,35 to 6,40 mm (0.250 to 0.252 in)

509467 6,45 to 6,50 mm (0.254 to 0.256 in)

509468 6,55 to 6,60 mm (0.258 to 0.260 in)

509469 6,65 to 6,70 mm (0.262 to 0.264 in)

509470 6,75 to 6,80 mm (0.266 to 0.268 in)

509471 6,85 to 6,90 mm (0.270 to 0.272 in)

509472 6,95 to 7,00 mm (0.274 to 0.276 in)

509473 7,05 to 7,10 mm (0.278 to 0.280 in)

509474 7,15 to 7,20 mm (0.281 to 0.283 in)

509475 7,25 to 7,30 mm (0.185 to 0.287 in)

509476 7,35 to 7,40 mm (0.289 to 0.291 in)

509477 7,45 to 7,50 mm (0.293 to 0.295 in)

509478 7,55 to 7,60 mm (0.297 to 0.299 in)

509479 7,65 to 7,70 mm (0.301 to 0.303 in)

509480 7,75 to 7,80 mm (0.305 to 0.307 in)

509481 7,85 to 7,90 mm (0.309 to 0.311 in)

509482 7,95 to 8,00 mm (0.313 to 0.315 in)

509483 8,05 to 8,10 mm (0.317 to 0.319 in)

509484 8,15 to 8,20 mm (0.321 to 0.323 in)

509485 8,25 to 8,30 mm (0.325 to 0.327 in)

509486 8,35 to 8,40 mm (0.329 to 0.331 in)

509487 8,45 to 8,50 mm (0.333 to 0.335 in)

509488 8,55 to 8,60 mm (0.337 to 0.339 in)

509489 8,65 to 8,70 mm (0.341 to 0.343 in)

509490 8,75 to 8,80 mm (0.344 to 0.346 in)

509491 8,85 to 8,90 mm (0.348 to 0.350 in)

Sizes of lower spring plates (A) available

Part Number Dimension ’X’

509498 0,60 to 0,65 mm (0.024 to 0.026)

509499 0,70 to 0,75 mm (0.028 to 0.030)

509500 0,80 to 0,85 mm (0.031 to 0.033)

509501 0,90 to 0,95 mm (0.035 to 0.037)

509502 1,00 to 1,05 mm (0.039 to 0.041)

509503 1,10 to 1,15 mm (0.043 to 0.045)

509504 1,20 to 1,25 mm (0.047 to 0.048)

509505 1,30 to 1,35 mm (0.051 to 0.053)

509506 1,40 to 1,45 mm (0.055 to 0.057)

509507 1,50 to 1,55 mm (0.059 to 0.061)

509508 1,60 to 1,65 mm (0.063 to 0.065)

509509 1,70 to 1,75 mm (0.067 to 0.069)

509510 1,80 to 1,85 mm (0.070 to 0.073)

509511 1,90 to 1,95 mm (0.075 to 0.077)

509512 2,00 to 2,05 mm (0.079 to 0.081)

509513 2,10 to 2,15 mm (0.083 to 0.085)

509514 2,20 to 2,25 mm (0.087 to 0.089)

509515 2,30 to 2,35 mm (0.091 to 0.093)

509516 2,40 to 2,45 mm (0.094 to 0.096)

509517 2,50 to 2,55 mm (0.098 to 0.100)

509518 2,60 to 2,65 mm (0.102 to 0.104)

509519 2,70 to 2,75 mm (0.106 to 0.108)

509520 2,80 to 2,85 mm (0.110 to 0.112)

509521 2,90 to 2,95 mm (0.114 to 0.116)

509522 3,00 to 3,05 mm (0.118 to 0.120)

509523 3,10 to 3,15 mm (0.122 to 0.124)

509524 3,20 to 3,25 mm (0.126 to 0.128)

509525 3,30 to 3,35 mm (0.130 to 0.132)

509526 3,40 to 3,45 mm (0.134 to 0.136)

509527 3,50 to 3,55 mm (0.138 to 0.140)

509528 0,60 to 0,65 mm (0.024 to 0.026)

If air enters the fuel system, the injection pump

pressure may become insufficient to operate the

injector valves and the engine may stop, misfire or fail

to start.

To eliminate air from the system, use the relevant

procedure which follows:

Low pressure system

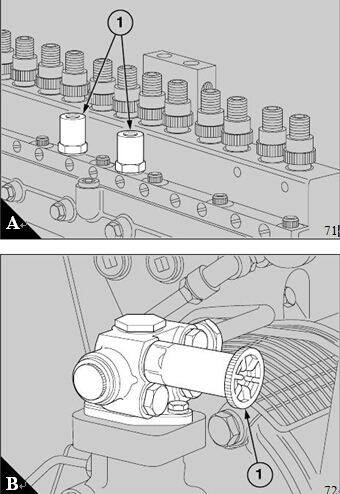

1 Loosen the low pressure relief valves (A1) on the

fuel injection pump and operate the priming plunger

(B1) of the fuel lift pump. When fuel, free from air,

flows from the relief valves, tighten the unions.

2 Clean away any fuel that has been spilled.

High-pressure system

Air in the high-pressure system must be releas ed at

the injectors.

1 Mov e the s top control to the RUN position and

operate the starter motor.

2 Loosen the nut of the high-pressure fuel pipe at one

of the injectors. When fuel, free from air, is released,

A

B

71

72

tighten the nut to a torque of 45 Nm (33 lbf ft). DO

NOT OVERTIGHTEN.

Warning! Ensure that fuel does not spray onto your

skin.

3 Repeat the procedure for the remainder of the fuel

injectors.

4 If the engine starts during this operation but runs

erratically, continue to eliminate air from each fuel

injector until the high-pressure sy stem is free from air

or until the engine runs correctly.

5 Return the stop control to the STOP position.

6 Clean away any fuel that has been spilled