详细描述

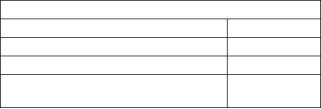

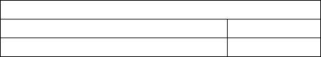

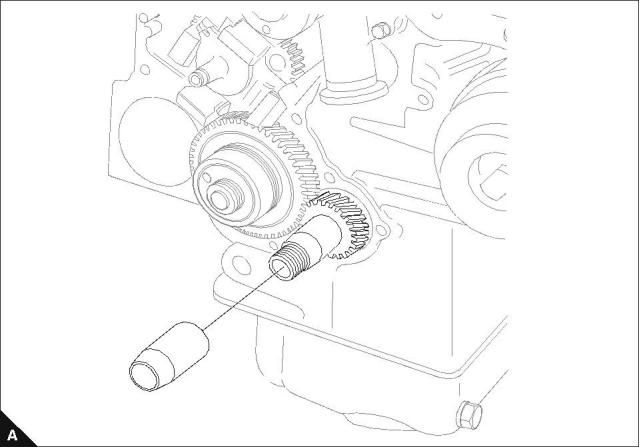

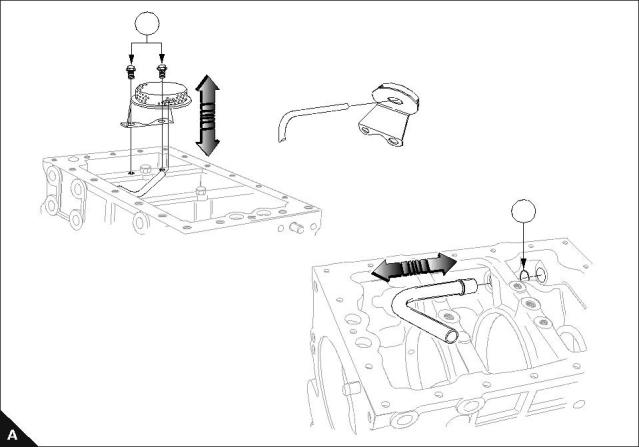

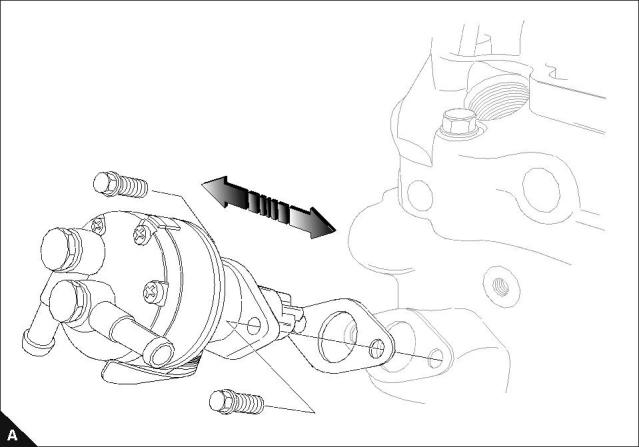

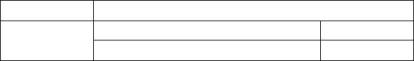

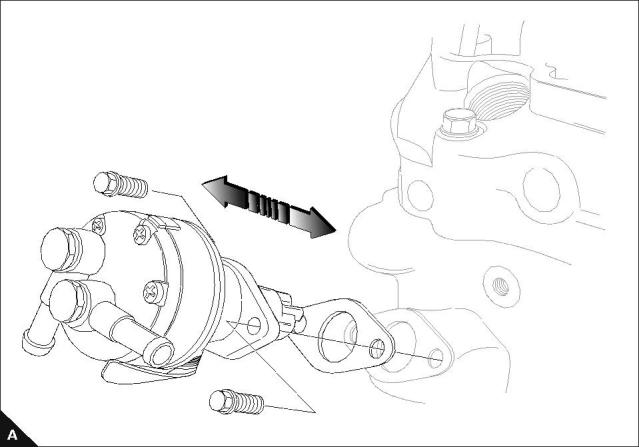

o remove and to fit

Operation 6-10

Special requirements

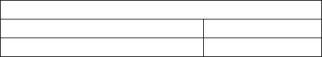

Clearance (B1) mm (in)

Standard

Service limit

0,01 - 0,15 (0.0004 - 0.0060)

0,25 (0.0098) max

Extra shims may be required to achieve the standard clearance. To check the end float refer to Operation 6-13.

1

Workshop Manual, TPD 1377E, issue 4

75

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

6

100 Series

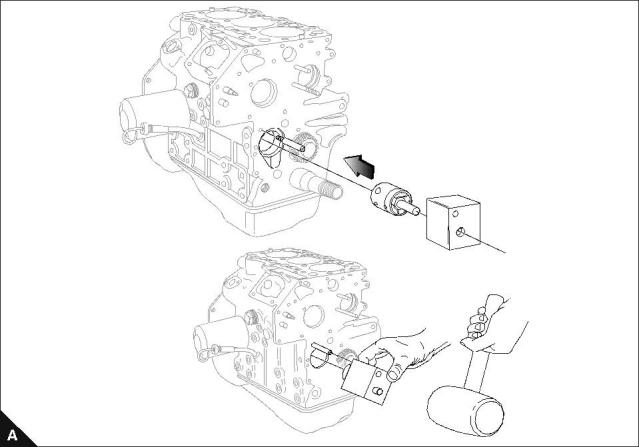

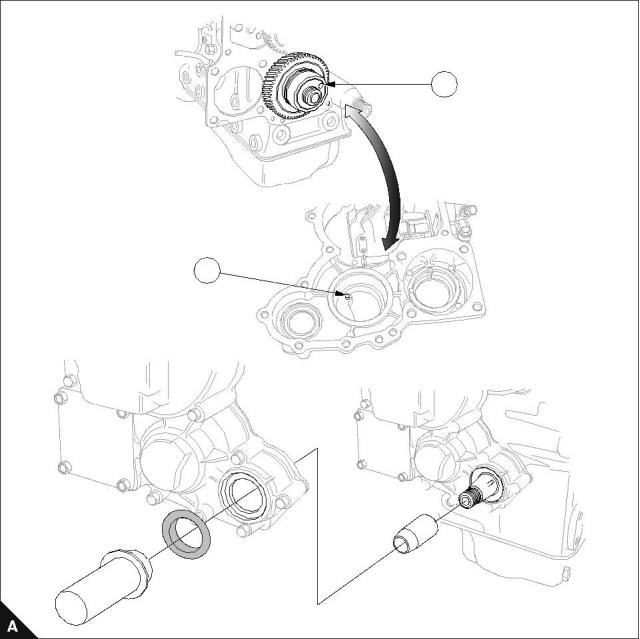

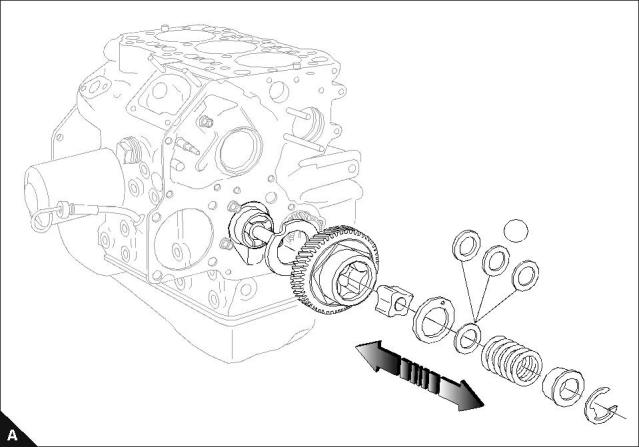

Idler hub

To fit

Operation 6-11

Special requirements

Special tools

Description

Part number

21825624

Idler hub assembly tool - 102-05, 103-07

Idler hub assembly tool - 103-10

21825625

Idler hub assembly tool - 103-13, 103-15,

104-19, 104-22

21825626

Caution: If the idler hub is removed, it must be renewed.

76

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

6

100 Series

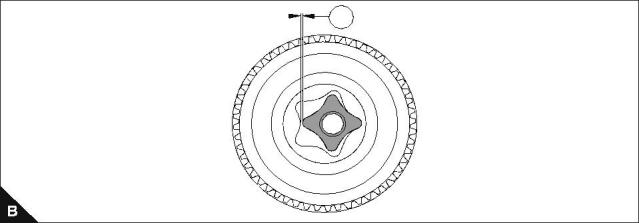

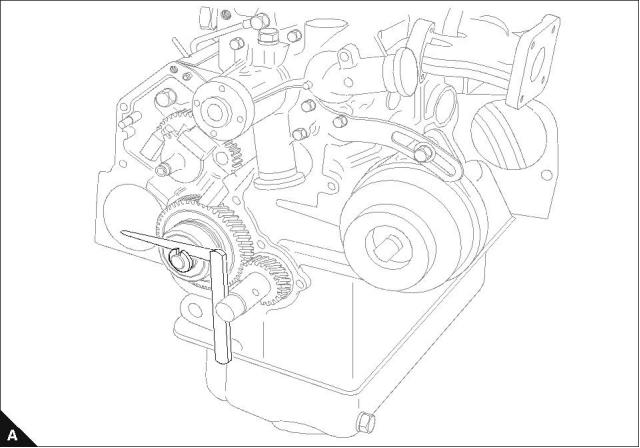

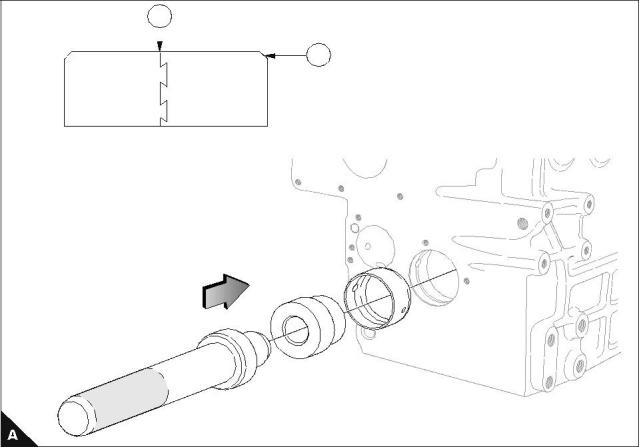

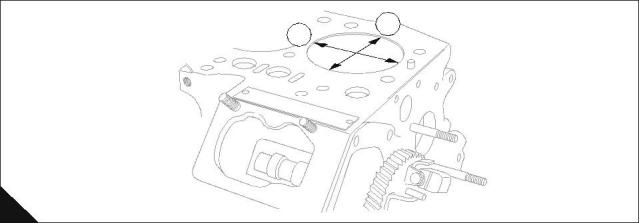

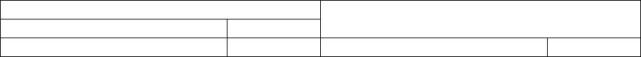

Gear teeth backlash

To check backlash

Operation 6-12

Special requirements

Timing gear tolerances mm (in)

Standard

Service limit

0,08 (0.0032)

0,25 (0.0098)

1 Align the set marks.

2 Measure the clearance with a feeler gauge.

Workshop Manual, TPD 1377E, issue 4

77

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

6

100 Series

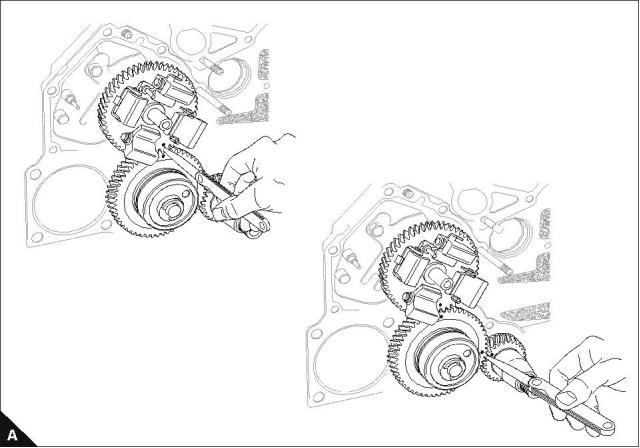

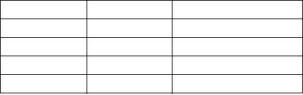

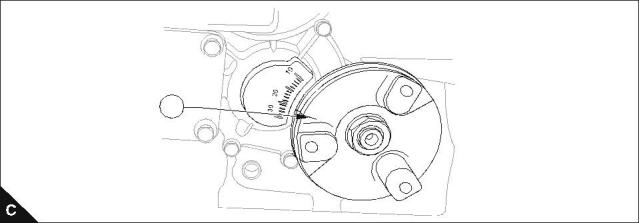

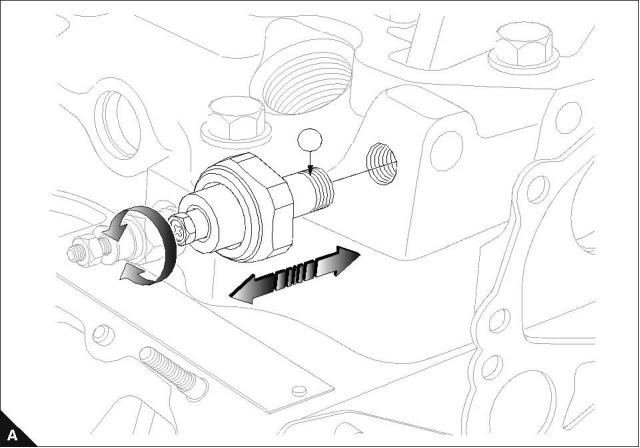

Oil pump end float

To check

Operation 6-13

Special requirements

Clearance mm (in)

Standard

Service limit

0,10 - 0,15 (0.0040 - 0.0060)

0,20 (0.0079)

Use a feeler gauge to check the end float clearance of the oil pump. Adjust with 0,1. 0,15. 0,2. and 0,5 mm

shims.

78

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

6

100 Series

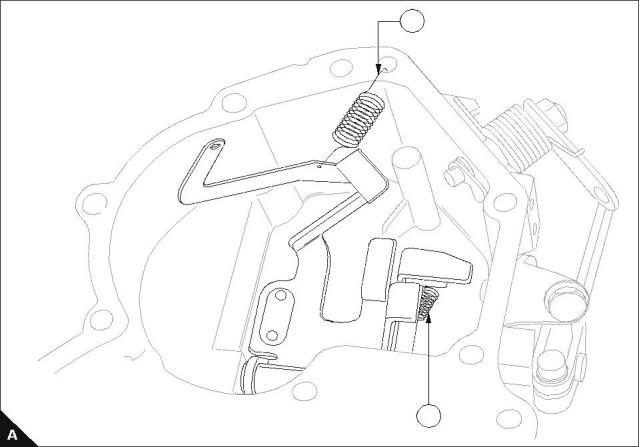

Governor spring

To locate and to check

Operation 6-14

The main governor springs are colour coded to assist with identification. The colour code is as follows:

Part Number

198217580

198217570

198217320

198217110

Description

Main Spring

Main Spring

Main Spring

Main Spring

Colour Code

Black

Purple

Yellow - green

Silver

Note: Remember the locations of the start spring (A1) and the governor spring (A2).

1

2

Workshop Manual, TPD 1377E, issue 4

79

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

6

100 Series

Oil seal protector

To fit

Operation 6-15

Note: Fit the oil seal protector before the timing cover is fitted.

80

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

6

100 Series

Timing cover

To fit

Operation 6-16

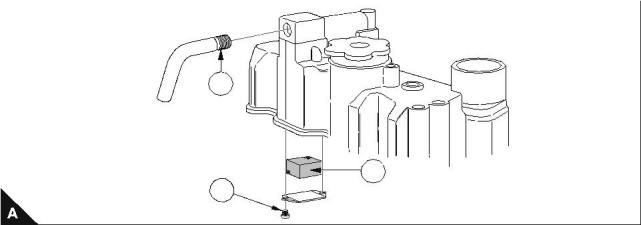

1 Ensure the oil pin (A1) locates in the hole (A2) in the idler gear.

2 Remove the oil seal protector after the timing cover is fitted. Fit the key onto the crankshaft nose, refer to

Operation 5-1.

3 To fit the crankshaft pulley refer to Operation 5-1.

2

1

Workshop Manual, TPD 1377E, issue 4

81

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

This page is intentionally blank

This document has been printed from SPI². Not for Resale

100 Series

7

Cylinder block assembly

7

Front bush

To fit

Operation 7-1

The bush must be fitted with the chamfered side (A2) into the block first, with the joint (A1) uppermost. To

remove, use the tool from the inside of the cylinder block.

Note: Make sure that the oil way in the bush is aligned with the oil way in the block.

1

2

Workshop Manual, TPD 1377E, issue 4

83

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

7

100 Series

Cylinder block top face

To inspect

Operation 7-2

Inspect the cylinder block top face for cracks, damage and distortion in the same way as for the cylinder head,

refer to Operation 3-19.

If outside limit, renew the cylinder block.

Distortion mm (in)

Standard

Service limit

Less than 0,05 (0.002)

0,12 (0.005)

Note: For emissions approved engines. If a new cylinder block is fitted, the engine should be tested on an

engine test brake and the fuel adjustment screw set. This procedures is only done by a Perkins approved

dealer. This will ensure that the engine will conform with emissions legislation.

2

1

A

84

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

100 Series

8

Engine timing

8

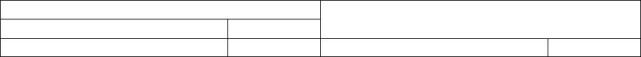

Fuel injection pump timing

To check timing

Operation 8-1

Special requirements

Special tools

Description

Torque Nm (lbf ft) kgf m

Part number

Fuel pump spill pipe

21825680

Delivery valve holder

42 (31) 4,2

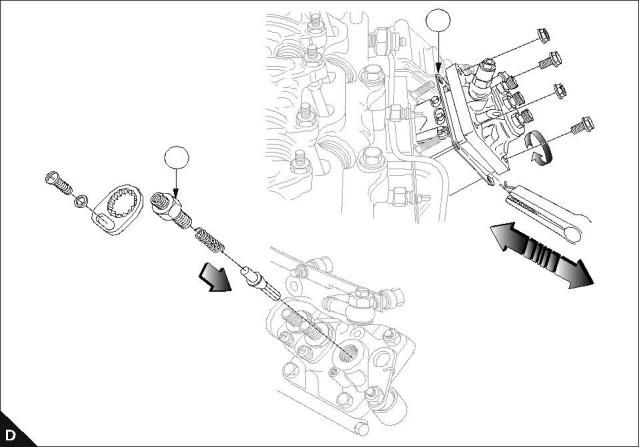

1 Set the piston for number 1 cylinder to TDC on the compression stroke. Turn the crankshaft counter-

clockwise a quarter of a revolution.

2 Disconnect or remove the ESOS, HP pipes and LP fuel inlet pipes from pump (A).

3 Ensure the throttle lever is held in the maximum fuel position after the procedure.

4 Remove the delivery valve holder for number 1 cylinder and remove the delivery valve. Store the delivery

valve in appropriate clean fuel until assembly.

Note: The fuel pump may need to be moved to an upright position to remove and to fit the delivery valves.

Continued

Workshop Manual, TPD 1377E, issue 4

85

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

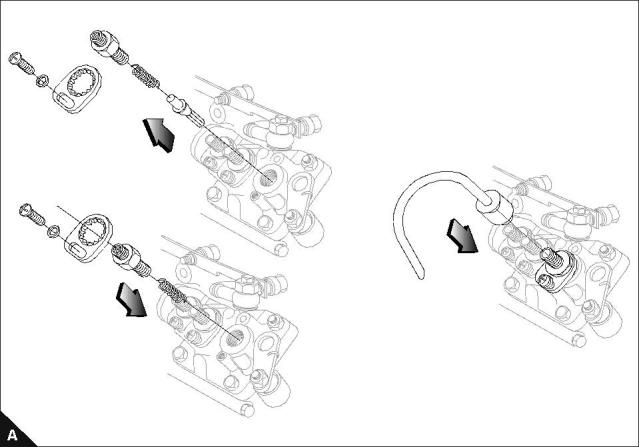

8

100 Series

5 Connect a suitable tank, which has a tap and contains 0,2 litres (¼ pint) of clean fuel, to the pump inlet.

6 Connect the fuel pump spill pipe to the delivery valve holder for number 1 cylinder. Put a suitable waste fuel

container below the pipe neck and open the tap, if correctly set fuel should flow (B).

Note: The outlet from the tank should be approximately 152 mm (6 in) above the pump.

7 Turn the crankshaft slowly until the flow of fuel reduces to a drop which falls from pipe neck every 7-10

seconds. This is then the timing point.

8 Use the value shown by the timing mark (C1) with the injection timing tables given in "Injection timing" on

page 15.

1

Continued

86

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

8

100 Series

9 If engine timing is incorrect adjust the thickness of shim (D2) to correct.

Note: If the shim thickness is adjusted by 0,1 mm, the timing will alter by approximately one degree. An

increase in the number of shims will retard the timing, but if the number of shims are decreased this will

advance the timing.

10 Fit the delivery valve.

Notes:

Ensure that the delivery valve holder (D1) is tightened to the specified torque.

For emissions approved engines. If it is necessary to change the fuel injection pump, the fuel delivery must

be reset on a suitable test dynamometer with the new pump. The procedure above, on injection pump

timing explains how to change the timing.

When changing the timing, it is important that this procedure is done before the engine is tested on a

suitable dynamometer.

2

1

Workshop Manual, TPD 1377E, issue 4

87

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

This page is intentionally blank

This document has been printed from SPI². Not for Resale

9

100 Series

Aspiration system

9

Breather system

To clean and renew

Operation 9-1

Cautions:

Failure to change a damaged, blocked or restricted engine breather hose may cause a back pressure in

the crankcase, causing premature failure of the rear engine oil seal.

Do not start an engine that is found to have a damaged, blocked or restricted breather hose, starting the

engine may cause damage to the rear engine oil seal.

Special requirements

POWERPART products

Description

Part number

21826039

Platelock

Threadlock

21820119 or 21820118

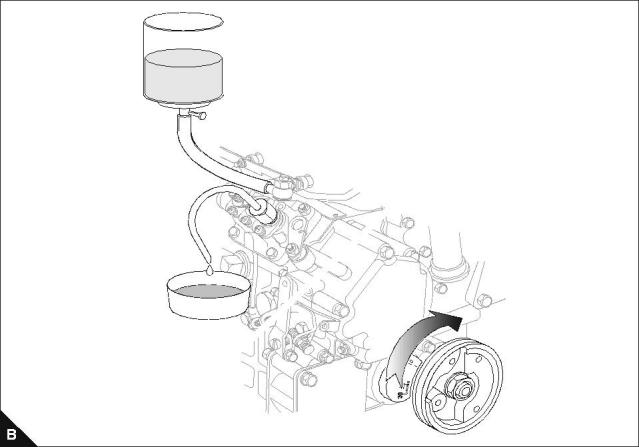

Clean the breather gauze (A2/B2) with suitable cleaning solvent. If damaged renew.

If the engine breather pipe (A1/B1) is damaged, blocked or restricted, it must be renewed.

On assembly, apply Powerpart Platelock to the threaded area on the breather pipes (A1/B1).

On assembly, apply Powerpart Threadlock to the threaded area on the setscrew (A3/B3).

102-05

103-07

103-10

1

2

3

103-13

103-15

104-19

104-22

1

2

33

Workshop Manual, TPD 1377E, issue 4

89

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

This page is intentionally blank

This document has been printed from SPI². Not for Resale

100 Series

10

Lubrication system

10

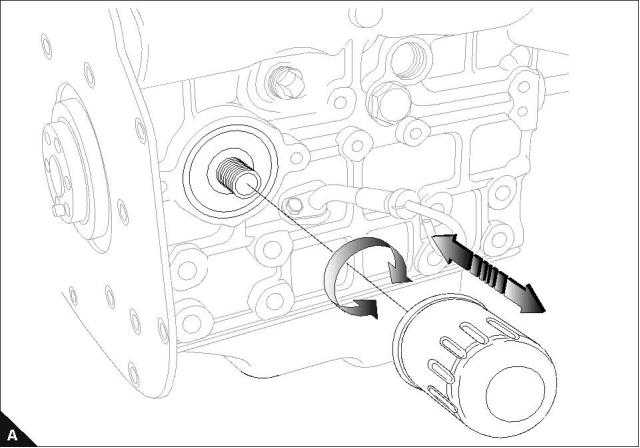

Oil filter canister

To remove and to fit

Operation 10-1

1 Remove the filter canister with a strap wrench or a similar tool and then discard the canister.

2 Clean the seal face of the filter head.

3 Lubricate the seal of the new canister with clean engine oil before assembly.

4 Install the new canister and tighten it by hand only. Do not use a strap wrench.

5 Tighten the canister by a further ½ to ¾ of a turn by hand only.

6 After the lubricating oil has been added to the sump, operate the engine and check for leakage from the

filter. When the engine has cooled, check the oil level on the dipstick and add oil to the sump, as necessary.

Caution: Do not use a strap wrench to tighten the filter canister.

Workshop Manual, TPD 1377E, issue 4

91

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

10

100 Series

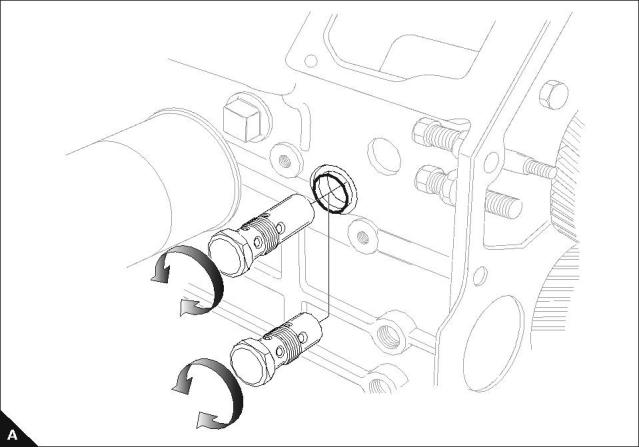

Pressure relief valve

To remove and to fit

Operation 10-2

Special requirements

Torque Nm (lbf ft) kgf m

Pressure relief valve

64 (47) 6,5

Renew the 'O' ring when the pressure relief valve is fitted to the cylinder block.

Caution: When the crankshaft is removed or fitted the pressure relief valve must be removed first.

102-05

103-07

103-10

103-13

103-15

104-19

104-22

92

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

10

100 Series

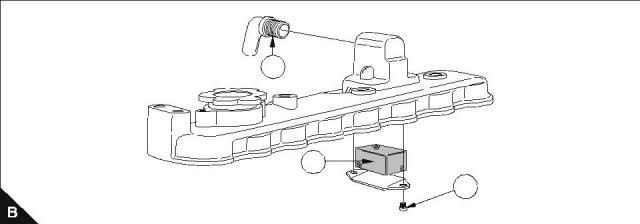

Lubricating oil sump

To remove and to fit

Operation 10-3

Special requirements

Torque Nm (lbf ft) kgf m

Sump setscrews

11 (8) 1,1

Note: When the sump is fitted renew the joint (A1).

1

Workshop Manual, TPD 1377E, issue 4

93

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

10

100 Series

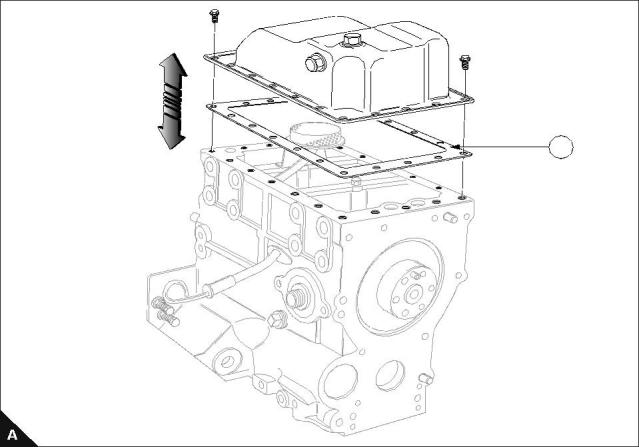

Strainer and suction pipe

To remove and to fit

Operation 10-4

Special requirements

Torque Nm (lbf ft) kgf m

Filter setscrews (A1)

11 (8) 1,1

Note: On assembly renew the 'O' ring (A2).

1

2

94

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

10

100 Series

Lubricating oil pump

To remove, to fit and to inspect

Operation 10-5

For the tolerances see "Idler gear and oil pump" on page 75 and "Oil pump end float" on page 78.

Note: Extra shims (A1) may be needed to achieve the standard clearance.

1

Workshop Manual, TPD 1377E, issue 4

95

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

10

100 Series

Oil pressure switch

To remove and to fit

Operation 10-6

Special requirements

POWERPART products

Torque Nm (lbf ft) kgf m

Description

Part number

Platelock

21826039

Oil pressure switch

11 (8) 1,1

Powerpart Platelock must be applied to the thread (A1) when the oil pressure switch is fitted to the cylinder

block.

Oil pressure switch range of operation 19,3 - 39,3 KPa (2.8-5.7 lbf/in²).

1

96

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

100 Series

11

Fuel system

11

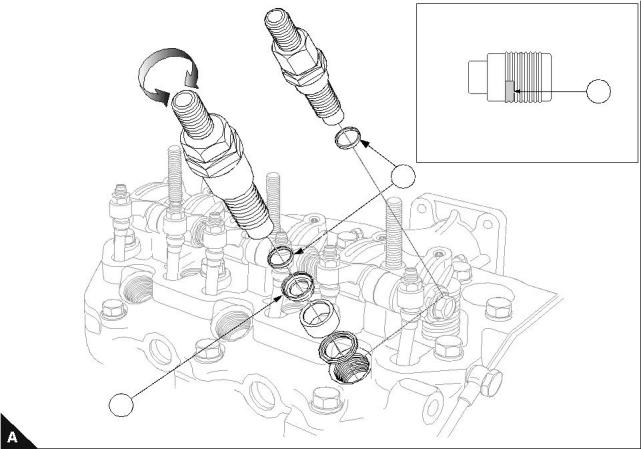

Atomisers

To remove

Operation 11-1

Cautions:

Deep sockets should always be used for this procedure.

Connections should be blanked off until assembly.

103-13

103-15

104-19

104-22

102-05

103-07

103-10

3

2

1

A

Workshop Manual, TPD 1377E, issue 4

97

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

11

100 Series

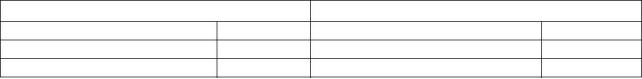

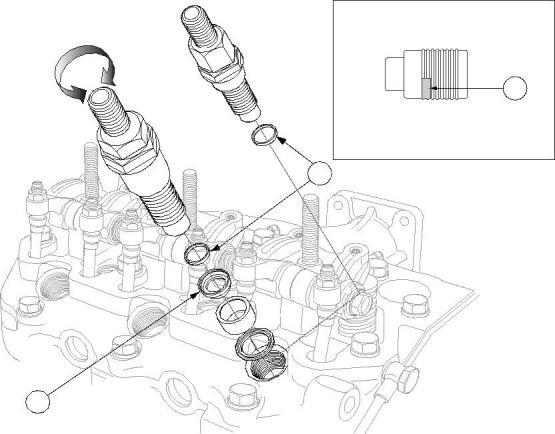

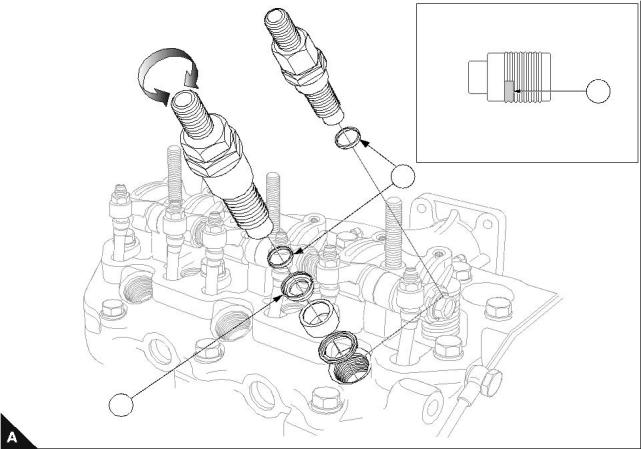

To fit

Operation 11-2

Special requirements

Torque Nm (lbf ft) kgf m

Test pressures kgf/cm² (lbf/in²) ats

102-05, 103-07

64 (47) 6,5

81 (60) 8,2

64 (47) 6,5

102-05, 103-07

120 (1707) 116

120 (1707) 116

150 (2133) 145

103-10

103-10

103-13, 103-15, 104-19, 104-22

103-13, 103-15, 104-19, 104-22

1 Clean and dry the male and female threads of the atomiser and the cylinder head.

2 Apply a 2 mm (0.08 in) bead of sealant POWERPART universal jointing compound, part number 1861117,

to extend 6 mm (0.24 in) along the first two threads of the atomiser (A3).

Engine serial numbers KR-----924551F to KR-----926370F require two nozzle washers (A2) fitted when

servicing any of the above engine serial numbers.

All 104-22 engines built from engine serial number KR-----926371F require one nozzle washer (A2) fitted when

servicing.

If a new cylinder head is fitted on engine serial numbers KR-----924551F to KR-----926370F then only one

nozzle washer (A2) is fitted.

Notes:

Item (A1) is used on 103-10 engine only.

Item (A2) is part number 131426200.

103-13

103-15

104-19

104-22

102-05

103-07

103-10

3

2

1

A

98

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

11

100 Series

Fuel lift pump

To remove and to fit early fuel lift pump

Operation 11-3

Note: Camshaft eccentric must be in the maximum lift position for the priming lever to operate correctly.

Workshop Manual, TPD 1377E, issue 4

99

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

11

100 Series

To remove and to fit the latest fuel lift pump

Operation 11-4

Engine

Torque Nm (lbf ft) kgf m

Lift pump setscrew

6 (4.4) 0,6

All models

Lift pump inlet adjusting bolt (A1)

2,5 (1.8) 0,25

The fuel inlet for the fuel lift pump can rotate 360° and is adjustable in 15° increments.

The fuel lift pump flange has two sets of locating holes this allows the pump to be fitted in four positions for the

outlet connection.

Note: Camshaft eccentric must be in the minimum lift position for the priming lever to operate correctly.

100

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

11

100 Series

To dismantle and to assemble the early fuel lift pump

Operation 11-5

Workshop Manual, TPD 1377E, issue 4

101

This document has been printed from SPI². Not for Resale

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska