详细描述

Troubleshooting

2206D-E13TA Industrial Engine

Table of Contents

Valve Lash Is Excessive .................................... 117

Valve Rotator or Spring Lock Is Free................... 118

Troubleshooting Section

Circuit Tests

Air Shutoff - Test................................................ 120

CAN Data Link - Test ......................................... 127

Coolant Level - Test........................................... 132

Data Link - Test................................................. 138

Electrical Power Supply - Test ............................ 143

Ether Starting Aid - Test..................................... 150

Indicator Lamp - Test......................................... 157

Injector Solenoid - Test ...................................... 160

Power Take-Off - Test........................................ 168

Retarder - Test.................................................. 174

Sensor Calibration Required - Test ..................... 180

Sensor Signal (Analog, Active) - Test.................. 183

Sensor Signal (Analog, Passive) - Test ............... 191

Sensor Supply - Test (8 V Supply) ...................... 198

Sensor Supply - Test (5V Supply) ....................... 204

Speed Control - Test.......................................... 206

Speed/Timing - Test .......................................... 208

Introduction

General Information ..............................................4

Welding Precaution ...............................................4

Electronic Service Tools.........................................5

Electronic System Overview

System Overview..................................................9

Component Location ........................................... 11

Diagnostic Capabilities ........................................13

Programmable Parameters..................................14

Electrical Connectors ..........................................16

Wiring Information...............................................20

Configuration Parameters

Configuration Parameters....................................21

Diagnostic Trouble Codes

Diagnostic Trouble Codes....................................28

Service

Customer Passwords ........................................ 214

Factory Passwords............................................ 214

ECM Will Not Accept Factory Passwords ............ 214

Electronic Service Tool Does Not Communicate ..215

Test ECM Mode ................................................ 221

Injector Trim File - Install.................................... 222

ECM Software - Install....................................... 223

ECM - Replace ................................................. 224

Electrical Connectors - Inspect........................... 225

Timing - Calibrate.............................................. 228

Event Codes

Event Codes ......................................................36

Symptom Troubleshooting

Symptom Troubleshooting ...................................42

Acceleration Is Poor or Throttle Response Is Poor .42

Alternator Problem ..............................................44

Battery Problem..................................................46

Coolant Contains Fuel.........................................46

Coolant Contains Oil ...........................................47

Coolant Level Is Low ...........................................50

Coolant Temperature Is High................................51

Cylinder Is Noisy.................................................54

ECM Does Not Communicate with Other Modules.56

Engine Cranks but Does Not Start ........................57

Engine Does Not Crank .......................................59

Engine Has Early Wear........................................61

Engine Has Mechanical Noise (Knock) .................63

Engine Misfires, Runs Rough or Is Unstable..........66

Engine Overspeeds.............................................68

Engine Shutdown Occurs Intermittently ................70

Engine Stalls at Low RPM....................................72

Engine Top Speed Is Not Obtained.......................74

Engine Vibration Is Excessive ..............................77

Exhaust Has Excessive Black Smoke...................78

Exhaust Has Excessive White Smoke...................80

Exhaust System Contains Oil...............................83

Exhaust Temperature Is High ...............................84

Fuel Consumption Is Excessive............................87

Fuel Pressure Is High ..........................................89

Fuel Pressure Is Low...........................................94

Fuel Temperature Is High.....................................98

Intake Manifold Air Temperature Is High.............. 104

Oil Consumption Is Excessive............................ 105

Oil Contains Coolant ......................................... 107

Oil Contains Fuel .............................................. 110

Oil Pressure Is Low ........................................... 111

Power Is Intermittently Low or Power Cutout Is

Index Section

Index................................................................ 233

Intermittent...................................................... 114

This document has been printed from SPI2. NOT FOR RESALE

![]()

4

UENR4542

Introduction

Troubleshooting Section

Introduction

Fault Detection and Reporting

The ECM monitors inputs from the sensors and

inputs from the applications control system. Software

in the ECM interprets the inputs. The software

determines if the inputs are operating correctly. A

diagnostic trouble code is activated when the

software detects a problem with an input.

The ECM broadcasts the codes on two data links.

The data links are the Perkins Data Link (PDL) and

J1939 CAN data link. The electronic service tool

must communicate on both data links in order to

service the engine. If a problem is suspected with

one of the data links, refer to Troubleshooting, “Data

Link - Test” or Troubleshooting, “CAN Data Link -

Test”.

i05957486

General Information

Overview

The codes can be displayed on the electronic service

tool and optional operator interfaces.

These engines are equipped with an electronic

control system. The system consists of a computer,

sensors, and software. The system provides these

capabilities:

Troubleshooting

As a reference, simplified schematics for each of the

engines subsystems are included with each of the

circuit tests that are in this manual. For an accurate

representation of the entire electrical schematic that

is for your application, refer to the Electrical System

Schematic.

• Control of the engine

• Applications control system interface

• Fault detection and reporting

During troubleshooting, inspect all harness

Electronic Control System

connections before any component is replaced. If

these connections are not clean and tight, continuous

electrical problems or intermittent electrical problems

can result. Check that the wires are pushed into the

connectors completely. Make sure that the

The Electronic Control Module (ECM) is a computer

that controls the operation of the engine.

The ECM contains a flash file. The flash file is the

software for the ECM. The flash file contains the

operating maps. The operating maps define the

following characteristics of the engine:

connections are tight before other tests are made.

Failure of an electrical component may cause the

failure of other components. Always attempt to

correct the cause of an electrical failure before you

replace a component. If wire insulation is punctured,

repair the damage.

• Horsepower

• Torque curves

• Engine speed (rpm)

Refer to Troubleshooting, “System Overview” for

additional information on the electronic control

system.

i05957501

Welding Precaution

Application Interface

The ECM interfaces with the machine via software

and an electrical connector on the ECM. The

software can be configured.

Proper welding procedures are necessary in

order to avoid damage to the engine Electronic

Control Module (ECM), to the Clean Emissions

Module (CEM), if equipped, to sensors, and to

associated components. Also consider

components that are for the driven equipment.

Remove the component that requires welding.

When welding on an engine that is equipped with

an ECM and removal of the component is not

possible, the following procedure must be

followed. This procedure provides the minimum

amount of risk to the electronic components.

The applications control system provides inputs to

the electrical connector on the ECM in order to

indicate the status of switches. Configure the ECM in

order to interpret the inputs.

The ECM provides outputs for the applications

control system via the electrical connector in order to

control lamps, solenoids, and other devices.

Configure the ECM to match the configuration of the

applications control system.

1. Stop the engine. Remove the electrical power from

the ECM.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

UENR4542

5

Introduction

2. Ensure that the fuel supply to the engine is turned

7. Use standard welding procedures to weld the

off.

materials together.

3. Disconnect the negative battery cable from the

battery. If a battery disconnect switch is installed,

open the switch.

i05957511

Electronic Service Tools

4. Disconnect all electronic components from the

wiring harnesses. Electronic components include

the following components:

Service Tools

• Electronic components for the driven

equipment

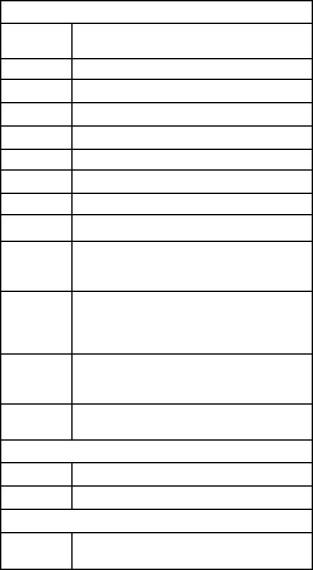

Most of the tools that are listed in Table 1 are

required to enable a service technician to perform the

test procedures in this manual. Some of the devices

may be specific to the type of Electronic Control

Module (ECM) that is being used.

• The engine ECM

• Sensors

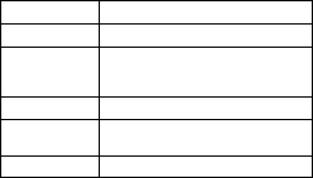

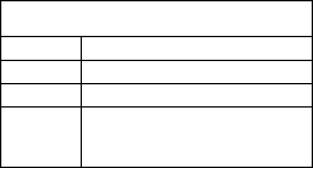

Table 1

Service Tools

NOTICE

Do NOT use electrical components (ECM or sensors)

or electronic component grounding points for ground-

ing the welder.

Part

Number

Description

N/A

4 mm Allen Wrench

Wedge Removal Tool

28170079

T400920

CH11155

Wire Removal Tool (14-GA TO 18-GA, RED)

Crimp Tool (12−AWG TO 18−AWG)

GE50038

GE50039

Transducer

Transducer Adapter

GE50040

CVT0019

Cable As

Adapter Cable As (3-PIN BREAKOUT)

T400922

T400923

Adapter Cable As (40-PIN BREAKOUT)

Harness (40-PIN)

(For ADEM 2 ECM (two 40-pin connectors))

GE50037 / Adapter Cable As (70-PIN BREAKOUT)

2900A025

T400924

N/A

(For ADEM 3 ECM (two 70-pin connectors) and

for ADEM 4 ECM (one 70-pin connector and one

120-pin connector))

Adapter Cable As (120-PIN BREAKOUT)

(For ADEM 4 ECM (one 70-pin connector and one

120-pin connector))

Torque Wrench (capable of applying 1.5 N·m

(13.3 lb in))

Illustration 1

g01143634

Service welding guide (typical diagram)

Repair Kits for Connectors

5. When possible, connect the welder ground clamp

directly to the engine component that will be

welded. Place the clamp as close as possible to

the weld. A close connection will reduce the

possibility of welding current damage to the engine

bearings, to the electrical components, and to

other components.

U5MK1110

U5MK8194

Connector Repair Kit (AMPSEAL)

Connector Repair Kit (Deutsch connector )

Bypass Harnesses for the ECM

T400925

Power Cable

(Stand alone cable for ADEM 2 ECM)

6. Protect the wiring harnesses from welding debris

and/or from the welding spatter.

(continued)

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

6

UENR4542

Introduction

(Table 1, contd)

• Programming of flash file

• Parameter programming

Service Tools

Part

Number

Description

• Copy configuration function for Electronic Control

Module (ECM) replacement

2900A038

Wiring Harness (ECM BYPASS)

(The bypass harness connects to the battery. The

bypass harness is used with the following har-

nesses for different types of electronic control

modules.)

• Data logging

• Graphs (real time)

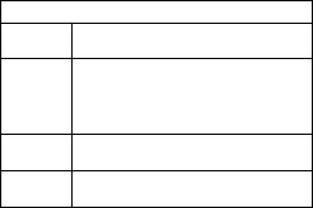

Table 3 lists the service tools that are required in

order to use the Electronic Service Tool.

Table 3

T400926

Harness (ENGINE ECM BYPASS)

(For ADEM 3 ECM and ADEM 4 ECM)

28170107

Harness (ENGINE ECM BYPASS)

(For A4:E2 ECM (Two 64-pin connectors))

Service Tools for the Use of the Electronic Service

Tool

Description

Single Use Program License

Data Subscription for All Engines

Part Number

Two short jumper wires may be needed to check the

continuity of some wiring harness circuits by shorting

two adjacent terminals together in a connector. A

long extension wire may also be needed to check the

continuity of some wiring harness circuits.

-(1)

-

(1)

27610164

TIPSS Adapter Kit (Electronic Service Tool to

Optional Service Tools

the ECM interface)

or

Table 2 lists the optional service tools that may be

needed during testing or repair.

27610401

Perkins CA3 Kit

(1)

Refer to Perkins Engine Company Limited.

Table 2

Note: For more information on the Electronic Service

Tool and the PC requirements, refer to the

documentation that accompanies the software for the

Electronic Service Tool.

Part Number

Description

U5MK1092

Spoon Probe Kit (MULTIMETER)

-

or

-

Suitable Digital Pressure Indicator

or

Engine Pressure Group

-

-

Suitable Battery Load Tester

Suitable Temperature Adapter

(MULTIMETER)

2900A038

Harness as

Perkins Electronic Service Tool

The Electronic Service Tool can display the following

information:

• Status of all pressure sensors and temperature

sensors

• Programmable parameter settings

• Active diagnostic codes and logged diagnostic

codes

• Logged events

• Histograms

The Electronic Service Tool can also be used to

perform the following functions:

• Diagnostic tests

• Calibrations

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

7

Introduction

Connecting the Electronic Service Tool

and the TIPSS Adapter

4. Place the keyswitch in the ON position. If the

Electronic Service Tool and the TIPSS adapter do

not communicate with the Electronic Control

Module (ECM), refer to the diagnostic procedure

Troubleshooting, “Electronic Service Tool Does

Not Communicate”.

Connecting the Electronic Service Tool

and the CA3 Kit

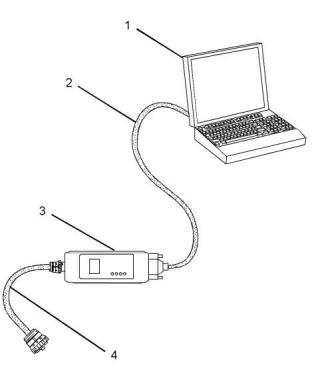

Illustration 2

g03738342

(1) Personal Computer (PC)

(2) Adapter Cable (Computer Serial Port)

(3) TIPSS adapter

(4) Adapter Cable Assembly

Note: Items (2), (3) and (4) are part of the TIPSS

adapter kit.

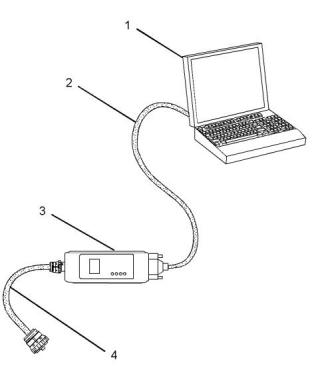

Illustration 3

g01121866

Use the following procedure in order to connect the

Electronic Service Tool and the TIPSS Adapter.

(1) Personal Computer (PC)

(2) Adapter Cable (Computer Serial Port)

(3) CA3 adapter

1. Turn the keyswitch to the OFF position.

(4) Adapter Cable Assembly

2. Connect cable (2) between the “COMPUTER” end

of TIPSS adapter (3) and the RS232 serial port of

PC (1).

Note: Items (2), (3) and (4) are part of the CA3 kit.

Use the following procedure in order to connect the

Electronic Service Tool and the CA3 Adapter.

Note: The Adapter Cable Assembly (4) is required to

connect to the USB port on computers that are not

equipped with an RS232 serial port.

1. Turn the keyswitch to the OFF position.

2. Connect cable (2) between the “COMPUTER” end

3. Connect cable (4) between the “DATA LINK” end

of TIPSS adapter (3) and the service tool

connector.

of CA3 adapter (3) and a USB port of PC (1).

3. Connect cable (4) between the “DATA LINK” end

of CA3 adapter (3) and the service tool connector.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

8

UENR4542

Introduction

4. Place the keyswitch in the ON position. If the

Electronic Service Tool and the CA3 adapter do

not communicate with the Electronic Control

Module (ECM), refer to the diagnostic procedure

Troubleshooting, “Electronic Service Tool Does

Not Communicate”.

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

9

Electronic System Overview

Electronic System

Overview

• Reduced warm-up time

• Reduced white smoke

Cold mode is activated whenever the engine

temperature falls below a predetermined value. Cold

mode remains active until the engine temperature

rises above a predetermined value or until a time limit

is exceeded.

i06299999

System Overview

Fuel Injection

The ECM controls the amount of fuel that is injected

by varying the signals to the injectors. The injector

will pump fuel only if the injector solenoid is

System Operation

energized. The ECM sends a high voltage signal to

the solenoid. This high voltage signal energizes the

solenoid. By controlling the timing and the duration of

the high voltage signal, the ECM can control injection

timing and the engine RPM.

This engine is electronically controlled. Each cylinder

has an electronic unit injector. The Electronic Control

Module (ECM) sends a signal to each injector

solenoid in order to control the operation of the fuel

injection system.

The flash file inside the ECM sets certain limits on the

amount of fuel that can be injected. The “FRC Fuel

Limit” is used to control the air/fuel ratio for control of

emissions. The “FRC Fuel Limit” is a limit that is

based on the turbocharger outlet pressure. A higher

turbocharger outlet pressure indicates that there is

more air in the cylinder. When the ECM senses a

higher turbocharger outlet pressure, the ECM

increases the “FRC Fuel Limit” . When the ECM

increases the “FRC Fuel Limit” , the ECM allows

more fuel into the cylinder. The “FRC Fuel Limit” is

programmed into the ECM at the factory. The “FRC

Fuel Limit” cannot be changed.

Electronic Controls

The electronic system consists of the following

components: the ECM, the Mechanically Actuated

Electronically Controlled Unit Injectors (MEUI), the

wiring harness, the switches and the sensors. The

ECM is the computer. The flash file is the software for

the computer. The flash file contains the operating

maps. The operating maps define the following

characteristics of the engine:

• Horsepower

The “Rated Fuel Limit” is a limit that is based on the

power rating of the engine and on engine rpm. The

“Rated Fuel Limit” is similar to the rack stops and to

the torque spring on a mechanically governed

engine. The “Rated Fuel Limit” provides the power

curves and the torque curves for a specific engine

family and for a specific engine rating. The “Rated

Fuel Limit” is programmed into the ECM at the

factory. The “Rated Fuel Limit” cannot be changed.

• Torque curves

The ECM determines the timing and the amount of

fuel that is delivered to the cylinders. These decisions

are based on the actual conditions and/or on the

desired conditions at any given time.

The ECM compares the desired engine speed to the

actual engine speed. The actual engine speed is

determined through a signal from the engine speed/

timing sensor. The desired engine speed is

determined with the following factors:

Once the ECM determines the amount of fuel that is

required, the ECM must determine the timing of the

fuel injection. The ECM calculates the TOP CENTER

position of each cylinder from the engine speed/

timing sensor signal. The ECM decides when fuel

injection should occur relative to the top center

position and the ECM provides the signal to the

injector at the desired time. The ECM adjusts timing

for optimum engine performance, for optimum fuel

economy, and for optimum control of white smoke.

• Throttle signal

• Other input signals from sensors

• Certain diagnostic codes

If the desired engine speed is greater than the actual

engine speed, the ECM injects more fuel in order to

increase the actual engine speed.

Programmable Parameters

Certain parameters that affect the engine operation

may be changed with the electronic service tool. The

parameters are stored in the ECM, and some

parameters are protected from unauthorized changes

by passwords. These passwords are called factory

passwords.

Cold Mode

The ECM limits engine power during cold mode

operation and the ECM modifies injection timing

during cold mode operation. Cold mode operation

provides the following benefits:

• Increased cold weather starting capability

This document has been printed from SPI2. NOT FOR RESALE

![]()

10

UENR4542

Electronic System Overview

Passwords

Several system configuration parameters and most

logged events are protected by factory passwords.

Factory passwords are available only to Perkins

distributors. Refer to Troubleshooting, “Factory

Passwords” for additional information.

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

11

Electronic System Overview

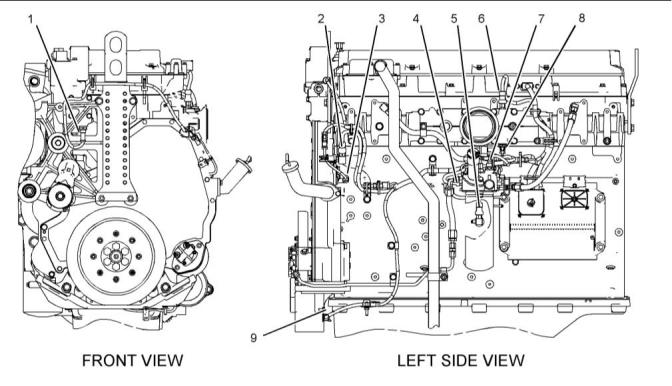

i06300000

Component Location

This document has been printed from SPI2. NOT FOR RESALE

![]()

12

UENR4542

Electronic System Overview

Illustration 4

g03891675

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

UENR4542

13

Electronic System Overview

2206D Engines

Illustration 5

g01099946

Locations of the sensors on 2206D engines

(1) Engine coolant temperature sensor

(2) Atmospheric pressure sensor

(3) Secondary engine speed/timing sensor

(4) Fuel pressure sensor

(5) Engine oil pressure sensor

(6) Boost pressure sensor

(7) Fuel temperature sensor

(8) Intake manifold air temperature sensor

(9) Primary engine speed/timing sensor

i05957583

Event Code – An event code is generated by the

detection of an abnormal engine operating condition.

For example, an event code will be generated if the

oil pressure is too low. In this case, the event code

indicates the symptom of a problem. Generally, event

codes indicate abnormal operating conditions or

mechanical problems rather than electrical problems.

Diagnostic Capabilities

Diagnostic Codes

The engines Electronic Control Module (ECM) can

monitor the circuitry between the ECM and the

engines components. The ECM can also monitor the

engines operating conditions. If the ECM detects a

problem, a code is generated.

Codes can have two different states:

• Active

• Logged

There are two categories of codes:

• Diagnostic code

Active Codes

An active code indicates that a problem is present.

Service the active code first. For the appropriate

troubleshooting procedure for a particular code, refer

to the appropriate troubleshooting procedure.

• Event code

Diagnostic Code – A diagnostic code indicates an

electrical problem such as a short circuit or an open

circuit in the engines wiring or in an electrical

component.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

14

UENR4542

Electronic System Overview

Logged Codes

active but the code may become logged.

Logged codes may not indicate that a repair is

needed. The problem may have been temporary.

Logged codes may be useful to help troubleshoot

intermittent problems. Logged codes can also be

used to review the performance of the engine and of

the electronic system.

The codes are logged and stored in the ECM

memory. The problem may have been repaired and/

or the problem may no longer exist. If the system is

powered, an active diagnostic code may be

generated whenever a component is disconnected. If

the component is reconnected, the code is no longer

i06534836

Programmable Parameters

Table 4

Diagnostic Trouble Codes

Code Description

J1939 Code

(code descriptions may

vary)

PDL Code

Comments

The Electronic Control Module (ECM) detects one of the following

conditions:

· One or more of the programmable parameters have not been

programmed

Engine Protection System · One or more of the injector trim files are not programmed.

630-2

268-2

Configuration : Erratic, Inter-

mittent, or Incorrect

The diagnostic code will only be active. The check engine lamp is il-

luminated when this diagnostic code is active.

Engine performance may be affected by unprogrammed parame-

ters. The unprogrammed parameters determine the action that is

taken by the ECM. The ECM may use a default torque map or the

ECM may limit the engine to low idle.

Programming Parameters

When the “Test ECM Mode” is activated, an internal

timer sets a 24-hour clock. This clock will count down

only when the ECM is powered. If the new ECM fixes

the problem, the engine can be released whilst the

“Test ECM Mode” is still active. After the ECM has

counted down the 24-hour period, the ECM will exit

the “Test ECM Mode” . The parameters, the

accumulated hours, and the engine serial number will

be permanently programmed into the new ECM. The

new ECM can no longer be used for another engine

or for a test ECM.

The electronic service tool can be used to view

certain parameters that can affect the operation of

the engine. The electronic service tool can also be

used to change certain parameters. The parameters

are stored in the Electronic Control Module (ECM).

Some of the parameters are protected from

unauthorized changes by passwords. Parameters

that can be changed have a tattletale number. The

tattletale number shows if a parameter has been

changed.

Note: When the “Test ECM Mode” is activated, the

“Personality Module Code” is 0. After the ECM has

counted down the 24-hour period, the “Personality

Module Code” depends on the application.

Test ECM Mode

“Test ECM Mode” is a feature on the electronic

service tool that is used to troubleshoot an engine

that may have a problem with the Electronic Control

Module (ECM).

If the new ECM does not resolve the problem, and 24

hours has not expired, the ECM can be used as a

new ECM. Anytime prior to the 24-hour limit of the

“Test ECM Mode” , a new engine serial number and

new parameters can be reprogrammed.

If an application supports this feature, the electronic

service tool will allow a new ECM to be used

temporarily as a test ECM. If an application does not

support this feature, refer to Troubleshooting, “ECM -

Replace”.

1. Search for the latest flash file for the engine.

Note: If a newer software version is available for the

engine, install the newest software on the suspect

ECM. If the new software does not fix the problem,

continue with this procedure.

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

15

Electronic System Overview

2. Use the “Copy Configuration/ECM Replacement”

feature on the electronic service tool to copy the

configuration parameters from the suspect ECM to

your personal computer (PC). If the “Copy

Configuration/ECM Replacement” feature cannot

be used, record the programmed values into the

“Parameters Worksheet” in system configuration

parameters Troubleshooting, “System

Configuration Parameters”. Record the injector

serial numbers from the “Calibrations” screen

under the “Service” menu on the electronic service

tool.

If the problem is resolved with the new ECM,

remove the original ECM and permanently install

the new ECM.

If the new ECM does not fix the problem, the

original ECM is not the problem. Remove the new

ECM before the 24-hour timer expires. Reconnect

the original ECM.

Flash Programming

Flash Programming – Flash programming is a

method of programming or updating the flash file in

an Electronic Control Module (ECM).

The electronic service tool is utilized to flash program

a flash file into the ECM. The flash programming

transfers the flash file from the PC to the ECM.

Note: Some applications use injectors that have trim

codes or injector trim files that are associated with

the injectors. If injector trim codes are necessary, the

injector trim codes are printed on the injector. If

injector trim files are necessary, the injector serial

numbers are necessary for obtaining the correct

injector trim files from the electronic service tool. The

injector trim file is a number that is specific to each

unit injector. The ECM uses this number to

Flash Programming a Flash File

1. Obtain the part number for the new flash file.

Note: If you do not have the part number for the flash

file, use “PTMI” on the Perkins secured web site.

compensate for manufacturing variations between

individual injectors. If any of the injectors are

replaced, the injector trim files must be programmed

for the new injectors. Also, if the ECM is replaced, all

the injector trim files must be programmed into the

new ECM.

Note: You must have the engine serial number to

search for the part number of the flash file.

2. Connect the electronic service tool to the

diagnostic connector.

3. Turn the keyswitch to the ON position. Do not start

the engine.

3. Disconnect the suspect ECM. Temporarily connect

the new ECM to the engine. Do not mount the new

ECM on the engine.

4. Select “WinFlash” from the “Utilities” menu on the

electronic service tool.

4. Program the correct flash file into the new ECM.

Note: If “WinFlash” will not communicate with the

ECM, refer to Troubleshooting, “Electronic Service

Tool Does Not Communicate”.

Note: The “Test ECM Mode” must be activated

before the engine serial number is programmed into

the new ECM. “Test ECM Mode” can only be

activated if the engine serial number has not already

been programmed during normal operation of the

ECM. A new ECM can never be used as a test ECM

after the engine serial number is programmed.

5. Flash program the flash file into the ECM.

a.

b.

Select the engine ECM under the “Detected

ECMs” .

5. Start the “Test ECM Mode” on the electronic

service tool. Access the feature through the

“Service” menu. The electronic service tool will

display the status of the “Test ECM Mode” and the

hours that are remaining for the “Test ECM Mode”

.

Press the “Browse” button to select the part

number of the flash file that will be

programmed into the ECM.

c.

d.

When the correct flash file is selected, press

the “Open” button.

Note: If the “Copy Configuration/ECM Replacement”

feature cannot be used, program the values from the

“Parameters Worksheet” .

Verify that the “File Values” match the

application. If the “File Values” do not match

the application, search for the correct flash file.

6. Use the “Copy Configuration/ECM Replacement”

feature on the electronic service tool to program

the correct parameters into the new ECM.

e.

f.

When the correct flash file is selected, press

the “Begin Flash” button.

The electronic service tool will indicate when

flash programming has been successfully

completed.

7. Program the engine serial number into the new

ECM.

This document has been printed from SPI2. NOT FOR RESALE

![]()

16

UENR4542

Electronic System Overview

6. Access the “Configuration” screen under the

“Service” menu to determine the parameters that

require programming.

“WinFlash” Error Messages

If any error messages are displayed during flash

programming, click the “Cancel” button to stop the

process. Access the information about the “ECM

Summary” under the “Information” menu. Ensure that

you are programming the correct flash file for your

engine.

7. Start the engine and check for proper operation.

Check that there are no active diagnostic codes.

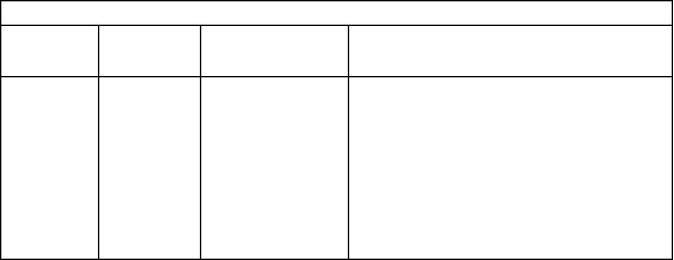

i06300006

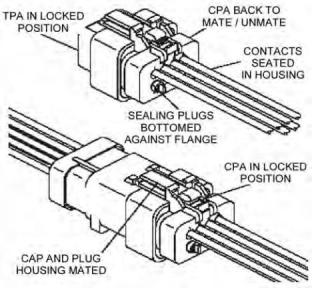

Electrical Connectors

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

17

Electronic System Overview

Connectors for the Electronic Control

Module (ECM)

Illustration 6

g02141017

Locations of the components at the Engine ECM

(1) P2 ECM connector (ECM side)

(2) P1 ECM connector (ECM side)

(3) P2 ECM connector (harness side)

(4) P1 ECM connector (harness side)

(5) Engine ECM

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

18

UENR4542

Electronic System Overview

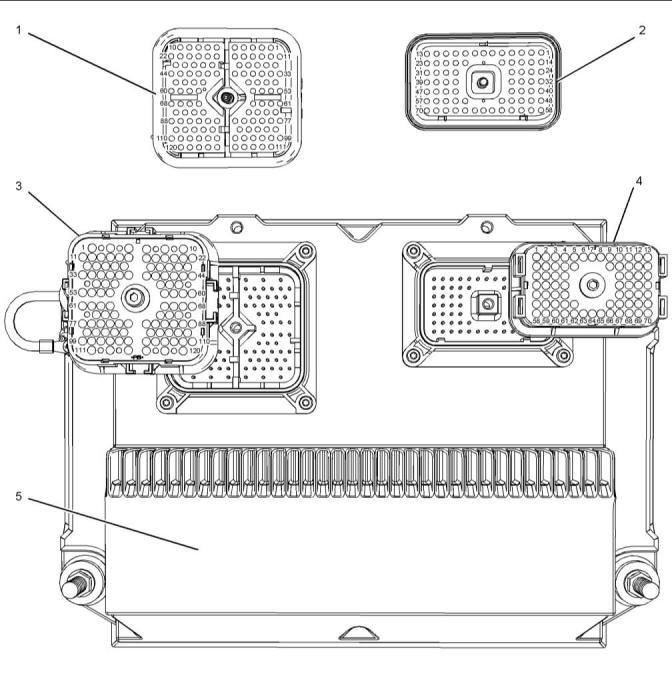

Injector Connectors

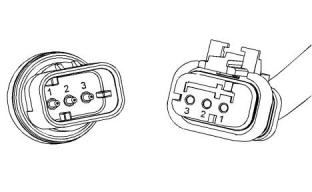

Sensor Connectors

Connectors at the Valve Cover

Analog Sensor Connector (active)

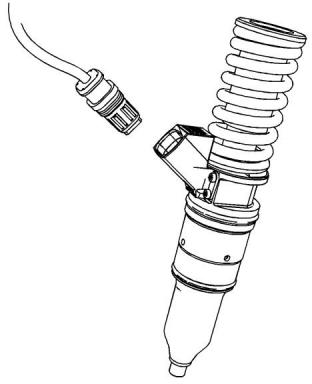

Illustration 7

g01746753

Illustration 9

g01240891

Connector at the Injector

Analog Sensor Connector (passive)

Illustration 10

g01241538

Illustration 8

g01717773

Typical HD injector

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4542

19

Electronic System Overview

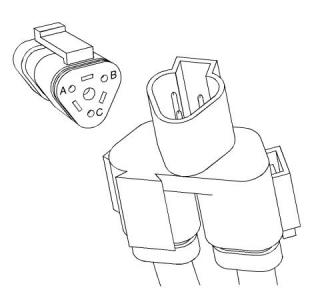

Connectors for the Termination Resistor

Ampseal Connector (typical)

Illustration 11

g01355248

Illustration 13

g02219254

Refer to Special Instruction, REHS2556 for additional

information

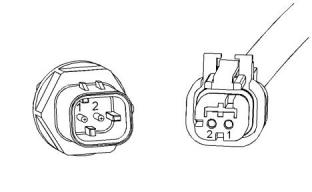

Engine Speed/Timing Connector

Illustration 12

g01155187

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

20

UENR4542

Electronic System Overview

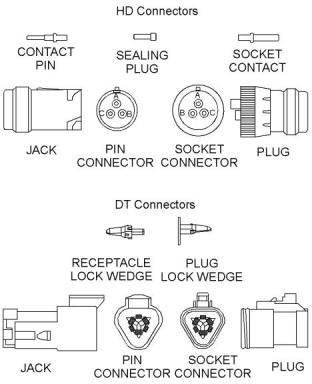

Deutsch Connectors (typical)

Table 5

Color Codes for the Harness Wire

Color Code

Color Code

Color

Color

BK

BR

RD

Black

GN

Green

Brown

Red

BU

PU

Blue

Purple

OR

YL

Orange

Yellow

GY

Gray

WH

PK

White

Pink

For example, a wire identification of A701-GY(Grey)

on the schematic would signify a gray wire with the

circuit number A701. A701-GY(Grey) identifies the

power circuit for the No. 1 Injector solenoid.

Illustration 14

g02220494

i05958935

Wiring Information

The connection of any electrical equipment and

the disconnection of any electrical equipment

may cause an explosion hazard which may result

in injury or death. Do not connect any electrical

equipment or disconnect any electrical equip-

ment in an explosive atmosphere.

The wiring schematics are revised periodically. The

wiring schematics will change as updates are made

to the engine harness. For the most current

information, always check the revision number of the

schematic. Use the schematic with the latest revision

number.

Harness Wire Identification

Wires are identified with 11 solid colors. The circuit

number is stamped on the wire at a 25 mm (1 inch)

spacing. Table 5 lists the wire colors and the color

codes.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

UENR4542

21

Configuration Parameters

Configuration Parameters

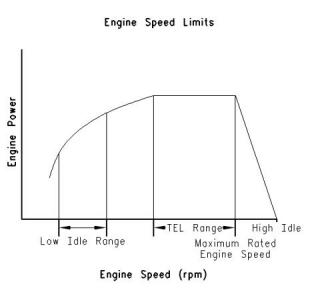

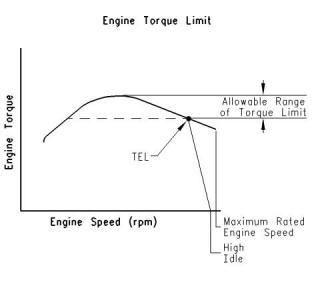

“Top Engine Limit” (TEL)

i06300016

Configuration Parameters

System configuration parameters are parameters

that affect the emissions and the power of the engine.

Default values for the parameters are programmed at

the factory. Some parameters may be changed by

the customer in order to suit the needs of the specific

application.

Parameter Descriptions

“Equipment ID”

“Equipment ID” allows the customer to enter a

description into the Electronic Control Module (ECM)

in order to identify the machine. A maximum of 17

characters may be entered in the field. This

parameter is only for reference by the customer. This

parameter is not required.

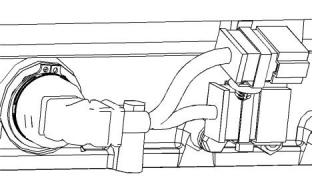

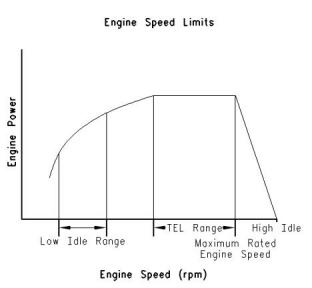

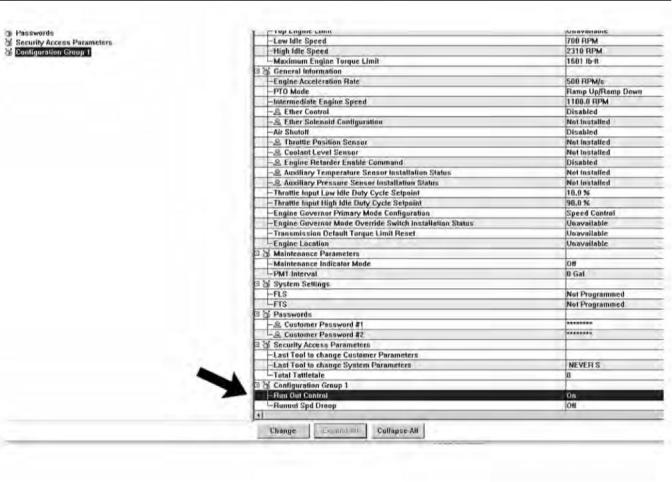

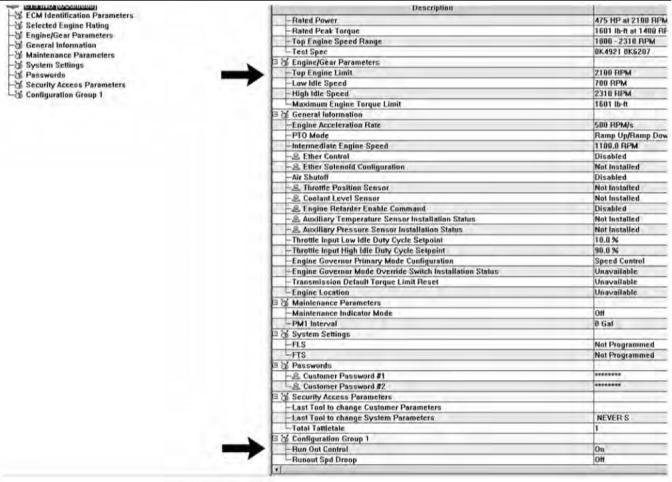

Illustration 15

g00763900

“TEL” is a customer programmable parameter that

defines the maximum allowable engine speed for

maximum power. “TEL” can be programmed up to

the maximum rated engine speed. “TEL” is defined

along the engine's lug curve.

“Engine Serial Number”

Program the “Engine Serial Number” to match the

engine serial number that is stamped on the engine

information plate. If the ECM is replaced, the engine

serial number from the engine information plate must

be programmed into the new ECM.

Programming the “Top Engine Limit”

In certain instances, the “TEL” must be programmed

using the procedure outlined below.

Note: When you are requesting factory passwords,

always use the engine serial number that is

programmed in the ECM.

“Rating Number”

The “Rating Number” corresponds to the selected set

of performance maps for the application. This

selected set of performance maps comes out of

several unique sets of maps that are resident in the

flash file. The dealer and/or the OEM will need to

select the appropriate rating tier, if more than one

rating tier is present. The rating tiers are “A” through

“E” .

Note: Factory passwords are required in order to

change the “Rating Number” .

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

22

UENR4542

Configuration Parameters

Illustration 16

g03891712

1. Program “Run Out Control” to “ON” , then

disconnect from the electronic service tool and

completely remove battery power from the ECM.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

UENR4542

23

Configuration Parameters

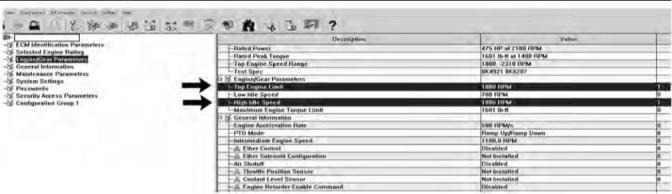

Illustration 17

g02897641

2. Restore the power. After power is restored,

program “Run Out Control” to “ON” . “Top Engine

,Limit” is now “2100 RPM” instead of “Unavailable”

.

Illustration 18

g03891716

3. Program “Top Engine Limit” to “1800 RPM” .

Program “High Idle Speed” to “1800 RPM” .

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

“Engine Accel. Rate”

“Intermediate Engine Speed”

24

UENR4542

Configuration Parameters

“Engine Accel. Rate” determines the rate of change

“Intermediate Engine Speed” defines the speed for

the engine when the intermediate engine speed

switch is activated. This parameter can be

programmed to any engine speed between “Low Idle

Speed” and “TEL” . Engine speed will increase or

engine speed will decrease at the rate that is defined

by the programmed value for “Engine Accel. Rate” .

of the engine speed (acceleration or deceleration)

during PTO operation. This rate of change is also

used to achieve intermediate engine speed.

“Low Idle Speed”

“Low Idle Speed” is the minimum allowable operating

speed for the engine. This parameter can be

programmed between 600 and 1400 rpm.

“Maximum Engine Torque Limit”

“PTO Mode”

“PTO Mode” allows the ECM to be programmed to

either one of the two PTO configurations that are

available.

“Ramp Up/Ramp Down” – When “PTO Mode” is

programmed to “Ramp Up/Ramp Down” , the ECM

allows PTO operation with traditional features.

“Set/Resume” – When “PTO Mode” is programmed

to “Set/Resume” , the ECM allows PTO operation

with enhanced features.

“High Idle Speed”

Illustration 20

g00817759

“Engine Torque Limit” can be used to limit torque

output to the programmed value when the torque limit

switch is activated.

“FLS” (Full Load Setting)

“FLS” is a number that represents the adjustment to

the fuel system that was made at the factory in order

to fine-tune the fuel system. The correct value for this

parameter is stamped on the engine information

plate. Factory passwords are required in order to

change this parameter.

“FTS” (Full Torque Setting)

“FTS” is similar to “FLS” . Factory passwords are

required in order to change this parameter.

Illustration 19

g00763900

“High Idle Speed” is the maximum no-load engine

speed when the throttle or the PTO switch is in the

maximum position.

“Ether Control”

Program the “Ether Control” to “Enabled” if an ether

injection system is installed on the engine. This

action allows the ECM to control ether injection. If the

engine is not equipped with ether, program this

parameter to “Disabled” .

Note: “High Idle Speed” cannot be programmed

lower than “TEL” .

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

“Air Shutoff”

“Aux Temp Sensor Installation Status”

UENR4542

25

Configuration Parameters

“Air Shutoff” allows the ECM to be programmed for

Program “Aux Temp Enable” to “Installed” if an

auxiliary temperature sensor is installed. This action

will allow the Perkins Messenger Driver Information

Display to monitor the temperature of another

system. Program this parameter to “Not Installed” if

an auxiliary temperature sensor is not installed.

operation of an air shutoff system. If this parameter is

programmed to “Installed” , the ECM will activate the

air shutoff solenoid in the event of an engine

overspeed condition.

Note: If an engine overspeed condition occurs and

“Air Shutoff” is programmed to “Enabled” , the

switched power to the ECM must be cycled and the

air shutoff solenoid must be manually reset before

the engine will restart.

“Maintenance Indicator Mode”

The ECM records data that is related to equipment

maintenance. The ECM will activate the maintenance

indicator lamp when scheduled maintenance is due.

The maintenance indicator lamp can be reset by

actuating the maintenance clear switch. The

maintenance interval may be based on operating

hours or on fuel consumption. The ECM provides

information that pertains to maintenance intervals

and the last maintenance that was performed.

“PM1 Interval”

“PM1 Interval” allows the customer to define the

maintenance interval if “Maintenance Indicator Mode”

is programmed to one of the manual options. Refer to

the engine's Operation and Maintenance Manual for

more information.

“Throttle Position Sensor”

Program the “Throttle Position Sensor” to “Installed” if

a throttle position sensor is used for desired speed

control. Otherwise program this parameter to “Not

Installed” .

“Coolant Level Sensor”

Program the “Coolant Level Sensor” to “Installed” if a

coolant level sensor is installed on the engine.

Otherwise program this parameter to “Not Installed” .

“Aux Press Sensor Installation Status”

Program “Aux Press Enable” to “Installed” if an

auxiliary pressure sensor is installed. This action will

allow the Perkins Messenger Driver Information

Display to monitor the pressure of another system.

Program this parameter to “Not Installed” if an

auxiliary pressure sensor is not installed.

This document has been printed from SPI2. NOT FOR RESALE

![]()

26

UENR4542

Configuration Parameters

System Configuration Parameters

Table 6

System Configuration Parameters

Required

Password

Parameter

Available Range or Options

Default

ECM Identification Parameters

“Equipment ID”

17 alphanumeric characters

0XX00000 or XXX00000

“NOT PROGRAMMED”

None

None

“Engine Serial Number”

0XX00000

“ECM Serial Number”

“Read Only” (1)

Software Dependent

“Software Gp Part Number”

“Software Gp Release Date”

Selected Engine Rating

“Rating Number”

Read Only (1)

Read Only (1)

Software Dependent

Software Dependent

Software Dependent

Software Dependent

Software Dependent

Software Dependent

Software Dependent

Customer

“Rated Power”

Read Only (1)

“Rated Peak Torque”

“Top Engine Speed Range”

“Test Spec”

Read Only (1)

Read Only (1)

Read Only (1)

“Top Engine Limit”

Customer

None

“Speed Control”

“Engine Governor Primary Mode”

“Speed Control”

“Min/Max”

50 to 1000

600 to 1400

“Engine Accel. Rate”

“Low Idle Speed”

50

None

None

700

“Ramp Up/Ramp Down”

“Set/Resume”

“PTO Mode”

“Ramp Up/Ramp Down”

None

“High Idle Speed”

1800 to 2310

2310

1100

Customer

None

“Intermediate Engine Speed”

“Maximum Engine Torque Limit”

Programmed “Low Idle” to “TEL”

Software Dependent

None

“Customer Password #1”

“Customer Password #2”

“FLS” (Full Load Setting)

“FTS” (Full Torque Setting)

8 alphanumeric characters

8 alphanumeric characters

- 128 to 127

Blank

Blank

0

Customer

Customer

Factory

Factory

-128 to 127

0

“No Ether”

“Continuous Flow”

“Ether Control”

“Air Shutoff”

“No Ether”

“Disabled”

None

None

“Enabled”

“Disabled”

“OFF”

“Auto Fuel”

“Auto Hour”

“Man Fuel”

“Man Hour”

“Maintenance Indicator Mode”

“OFF”

None

(continued)

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

27

Configuration Parameters

(Table 6, contd)

System Configuration Parameters

Available Range or Options

Required

Password

Parameter

Default

100 to 750 Hours

or

250 Hours

or

“PM1 Interval”

None

3785 to 28390 L (1000 to 7500 US gal)

9463 L (2500 US gal)

“Installed”

“Not Installed”

“Throttle Position Sensor”

“Coolant Level On”

“Not Installed”

“Not Installed”

None

None

“Installed”

“Not Installed”

“Last Tool to change Customer

Parameters”

Read Only (1)

“Last Tool to change System

Parameters”

Read Only (1)

“On”

“Off”

“Aux Temp Sensor Installation Status”

“Off”

“Off”

None

None

“Aux Press Sensor Installation

Status”

“On”

“Off”

“Total Tattletale”

Read Only (1)

(1)

The parameter can only be viewed. No changes are allowed.

This document has been printed from SPI2. NOT FOR RESALE

![]()

28

UENR4542

Diagnostic Trouble Codes

Diagnostic Trouble Codes

i06300002

Diagnostic Trouble Codes

Diagnostic Trouble Codes in J1939

Order

Table 7 lists the diagnostic trouble codes that apply to

the engine. The codes are listed in J1939 order. Use

the electronic service tool to determine the codes that

are active or logged. Then refer to the appropriate

troubleshooting procedure for more information.

Table 7

List of Diagnostic Trouble Codes

J1939 Code and Description

PDL Code and Description

Troubleshooting Procedure

91–3

Accelerator Pedal Position #1 : Voltage Above

Normal

91–3

Throttle Position Sensor : Voltage Above

Normal

Troubleshooting, “Speed Control - Test”

Troubleshooting, “Speed Control - Test”

Troubleshooting, “Speed Control - Test”

91–4

Accelerator Pedal Position #1 : Voltage Below

Normal

91–4

Throttle Position Sensor : Voltage Below

Normal

91–8

91–8

Accelerator Pedal Position #1 : Abnormal Fre-

quency, Pulse Width or Period

Throttle Position Sensor : Abnormal Fre-

quency, Pulse Width, or Period

94–3

Engine Fuel Delivery Pressure : Voltage Above

Normal

94–3

Fuel Delivery Pressure Sensor : Voltage

Above Normal

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

94–4

Engine Fuel Delivery Pressure : Voltage Below Fuel Delivery Pressure Sensor : Voltage Below

94–4

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

Normal

Normal

94–13

Engine Fuel Delivery Pressure : Out of

Calibration

94–13

Fuel Delivery Pressure Sensor : Out of

Calibration

Troubleshooting, “Sensor Calibration Required

- Test”

100–3

Engine Oil Pressure : Voltage Above Normal

100–3

Engine Oil Pressure Sensor : Voltage Above

Normal

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

100–4

Engine Oil Pressure : Voltage Below Normal

100–4

Engine Oil Pressure Sensor : Voltage Below

Normal

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

100–13

Engine Oil Pressure : Out of Calibration

100–13

Engine Oil Pressure Sensor : Out of

Calibration

Troubleshooting, “Sensor Calibration Required

- Test”

105–3

Engine Intake Manifold #1 Temperature : Volt- Intake Manifold Air Temperature Sensor : Volt-

age Above Normal age Above Normal

172–3

Troubleshooting, “Sensor Signal (Analog, Pas-

sive) - Test”

(continued)

This document has been printed from SPI2. NOT FOR RESALE

![]()

UENR4542

29

Diagnostic Trouble Codes

(Table 7, contd)

105–4

Engine Intake Manifold #1 Temperature : Volt- Intake Manifold Air Temperature Sensor : Volt-

172–4

Troubleshooting, “Sensor Signal (Analog, Pas-

sive) - Test”

age Below Normal

age Below Normal

108–3

Barometric Pressure : Voltage Above Normal Atmospheric Pressure Sensor : Voltage Above

Normal

274–3

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

108–4

Barometric Pressure : Voltage Below Normal Atmospheric Pressure Sensor : Voltage Below

Normal

274–4

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

110–3

Engine Coolant Temperature : Voltage Above Engine Coolant Temperature Sensor : Voltage

110–3

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

Normal

Above Normal

110–4

Engine Coolant Temperature : Voltage Below Engine Coolant Temperature Sensor : Voltage

110–4

Troubleshooting, “Sensor Signal (Analog, Ac-

tive) - Test”

Normal

Below Normal

168-2

Battery Potential / Power Input #1 : Erratic, In- Electrical System Voltage : Erratic, Intermit-

168-2

Troubleshooting, “Electrical Power Supply -

Test”

termittent, or Incorrect

tent, or Incorrect

168-3

Battery Potential / Power Input #1 : Voltage

Above Normal

168-3

Electrical System Voltage : Voltage Above

Normal

Troubleshooting, “Electrical Power Supply -

Test”

168-4

Battery Potential / Power Input #1 : Voltage

Below Normal

168-4

Electrical System Voltage : Voltage Below

Normal

Troubleshooting, “Electrical Power Supply -

Test”

174–3

Engine Fuel Temperature 1 : Voltage Above

Normal

174–3

Fuel Temperature Sensor : Voltage Above

Normal

Troubleshooting, “Sensor Signal (Analog, Pas-

sive) - Test”

174–4

Engine Fuel Temperature 1 : Voltage Below

Normal

174–4

Fuel Temperature Sensor : Voltage Below

Normal

Troubleshooting, “Sensor Signal (Analog, Pas-

sive) - Test”

190–8

190–8

Troubleshooting, “Speed/Timing - Test”

Engine Speed : Abnormal Frequency, Pulse Engine Speed Sensor : Abnormal Frequency,

Width, or Period

Pulse Width, or Period

441–3

Auxiliary Temperature #1 : Voltage Above

Normal

1836–3

Auxiliary Temperature Sensor : Voltage Above

Normal

Troubleshooting, “Sensor Signal (Analog, Pas-

sive) - Test”

441–4

Auxiliary Temperature #1 : Voltage Below

Normal

1836–4

Auxiliary Temperature Sensor : Voltage Below

Normal

Troubleshooting, “Sensor Signal (Analog, Pas-

sive) - Test”

626-5

Engine Start Enable Device 1 : Current Below Ether Injection Control Solenoid : Current Be-

Normal

2417-5

Troubleshooting, “Ether Starting Aid - Test”

Troubleshooting, “Ether Starting Aid - Test”

Troubleshooting, “Programmable Parameters”

Troubleshooting, “ECM Software - Install”

low Normal

626-6

Engine Start Enable Device 1 : Current Above

Normal

2417-6

Ether Injection Control Solenoid : Current

Above Normal

630-2

Calibration Memory : Erratic, Intermittent, or

Incorrect

268-2

Programmed Parameter Fault : Erratic, Inter-

mittent, or Incorrect

631–2

Calibration Module : Erratic, Intermittent, or

Incorrect

253–2

Personality Module : Erratic, Intermittent, or

Incorrect

(continued)

This document has been printed from SPI2. NOT FOR RESALE

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska