Perkins3012发动机喷油器故障的检查与维修

Perkins3012发动机喷油器故障的检查与维修

Perkins3012发动机喷油器故障的检查与维修

A fuel injector fault c an cause an engine misfire.

喷油器故障C引起Perkins3012发动机失火。

In order to find which injector is defective, operate the

为了找到该喷油器是有缺陷的,操作

engine at a fast idle speed. Loosen and tighten the

Perkins3012发动机处于怠速转速。放松和收紧

union nut of the high-pressure fuel pipe at each

高压燃油管接头螺母

injector. When the union nut of the defective injector

喷油器。当联合螺母的有缺陷的喷油器

is loosened, it has little or no effect on the engine

被松了,它对Perkins3012发动机的影响不大

speed.

速度。

Warning! Ensure that the fuel does not spray onto

警告!确保燃油不喷到

your skin.

你的皮肤。

How to remove the fuel injectors

如何拆卸喷油器

1 Disconnect and remove the high-pressure pipes

1断开并拆下高压管道

and the spill pipes. For early engines, remove the

和泄漏管道。对于早期的Perkins3012发动机,删除

relevant rocker box cover. Release the connection for

相关摇杆箱盖。释放连接

the leak-off fuel from the fuel injector and remove it

燃油喷射器上的泄漏燃油并将其拆下

through the wall of the rocker box. For later engines,

通过摇杆箱的墙。对于后来的Perkins3012发动机,

remove the relevant pedestal rocker cover.

拆下相关的底座摇杆盖。

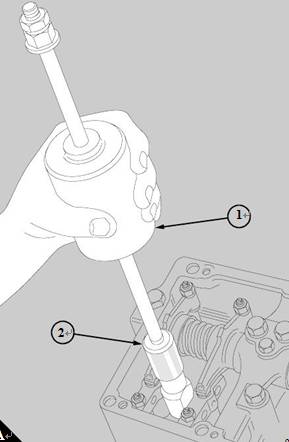

2 Release the relevant clamp and withdraw the fuel

2释放相关的夹具并提取燃油

injector. To remove a tight fuel injector, use the Slide

喷油器。要移除燃油喷射器,使用幻灯片

Hammer, 21825 849 (A1) and the relevant Adaptor

锤,21825 849(A1)和相关的适配器

(A2): 21825 854 for M18 threads or 21825 860 for

(A2):21825 854或21825 860 M18螺纹

M14 threads.

M14螺纹。

Caution: Ensure that the copper fuel injector sleeve

警告:确保铜燃油喷射套管

is not loosened in the cylinder head during the use of

在使用过程中不松动的气缸盖

How to correct the fuel injector sleeves

如何正确的喷油器套筒

To improve the condition of the injector sleeves, us e

为了改善喷油器套筒的情况,我们的

the Reamer/facer tool for the injector sleeve. Grease

用注射器套刀/机工具。润滑脂

must be applied to both of the cutters before use, to

在使用之前,必须将其应用于刀具前

retain carbon and metal particles. Do not remove

保留碳和金属粒子。不要删除

more metal than is absolutely necessary to correct the

金属比绝对要正确

seat face. The max imum permissible depth of the

座面。的最大允许深度

seat face, measured from the top face of the cylinder

座椅面,测量从气缸顶部的面

head, is 104,25 mm (4.104 in).

头,是104,25毫米(4.104英寸)。

Note: The Reamer/facer tool is assembled from

注:铰刀/机工具组装

these tools: 21825 765, 21825 767 and 21825 768.

这些工具:765 21825,767 21825和768 21825。

How to fit the fuel injectors

如何安装喷油器

1 Check that the new injector is fitted with a new ‘O’

1检查新的喷油器是否安装了一个新的“邻”

ring seal in the machined groove near to the top of the

在加工槽附近的环密封的顶部

stem and check that the sleeve for each fuel injector

阀杆和检查各喷油嘴的套筒

is c lean.

是靠。

2 If relevant, remove the connection for the leak-off

2如果有相关的话,删除连接泄漏

fuel from each fuel injector and fit carefully each fuel

燃油从每一个喷油器,并小心地每燃料

injector into its sleeve, with the threaded hole for the

喷油器为其套筒,用螺纹孔为

leak-off fuel toward the outer wall of the rocker box.

向摇杆箱外壁泄漏燃料。

DO NOT use a sealing washer between the injector

不要使用喷油器之间的密封垫圈

and the seating face of the injector sleeve

喷油嘴的密封面

3 Fit the assembly of the metal cup and rubber seal

3配合金属杯和橡胶密封件的装配

against the head of each connection for leak-off fuel

对泄漏燃料的每一个连接头

and fit a new copper washer onto the thread. For

在螺纹上安装一个新的铜垫圈。对于

early engines, insert each connection through the

早期的引擎,插入每个连接通过

openings in the outer walls of the rocker boxes and fit

在摇杆框和配合的外壁上的开口

the connection into its fuel injector, finger-tight.

连接到喷油器,手指紧。

4 Fit the clamps to the relevant fuel injectors,

4将夹具安装到相应的喷油器,

complete with a spherical washer for each clamp. Fit

用一个球形垫圈来完成每个夹子。适合

the cap screws through the washers and the clamps

帽螺丝通过垫圈和夹子

and tighten them to 60 Nm (44 lbf ft). For early

拧紧60牛米(44磅英尺)。早期

engines, when all the cap screws of the clamps are

Perkins3012发动机,当所有的盖螺钉的卡箍

tight, tighten the connections for leak-off fuel to 27 Nm

紧,拧紧泄漏燃料的连接到27纳米

(20 lbf ft).

(20磅英尺)。

5 Check that the joint face of each rocker box is

5检查各摇杆箱的接头面是否

c lean. Fit a new joint for each rocker box cover and

C精益。为每个摇杆箱盖安装新接头

align correctly the bolt holes.

正确对齐螺栓孔。

6 Fit c arefully each roc ker box cover and fit the

6适合C全每个ROC芋箱盖并安装

eight bolts , complete with plain and spring was hers.

八个螺栓,完全用平和弹簧是她的。

Tighten the bolts to 27 Nm (20 lbf ft). For later

拧紧螺栓27牛米(20磅英尺)。以后

engines, fit a new ‘O’ ring around the groove near

Perkins3012发动机,配合一个新的'邻'环附近的槽附近

the top of each fuel injector. Fit the pedes tal roc ker

各喷油器顶部。适合足鲎ROC芋

cover and tighten lightly all of the bolts . Tighten

盖并拧紧所有螺栓。拧紧

ev enly all of the bolts, in the s equence shown (A),

电动车突然所有的螺栓,在序列显示(一),

to a torque of 11 Nm (8 lbf ft).

到11 Nm的扭矩(8磅英尺)。

7 For all engines, fit new copper sealing washer to

7为所有Perkins3012发动机,安装新的铜密封垫圈

the connections for leak-off fuel and fit the pipes

泄漏燃料的连接和安装管道

between the fuel injectors and the connection block

在燃油喷射器和连接块之间

for the leak-off fuel. Tighten securely each banjo bolt

为泄漏燃料。安全拧紧每个空心螺栓

connection and each union nut.

连接及各连接螺母。

8 Fit each high-pressure fuel pipe between its

8配合各高压燃料管之间

delivery valve and its fuel injector. Tighten by hand

输送阀及其燃油喷射器。用手拧紧

each nut. DO NOT bend a pipe to make it fit between

每一个螺母。不要弯曲管道使其适合于

its connections. Tighten securely each nut to 45 Nm

它的连接。拧紧每个螺母至45纳米

(33 lbf ft).

(33磅英尺)。

Note: The identification of each high-pressure fuel

注:每一个高压燃料的识别

pipe is made by the cylinder number which is stamped

管是由缸号,这是加盖

on the union nut which is fitted to the fuel injector.

在燃油喷射器上安装的联螺母。

9 Fit new rubber dampers around each high-pressure

9安装新的橡胶减震器周围的每一个高压

fuel pipe. Fit the shrouds over the rubber dampers

燃料管。将笼罩在橡胶阻尼器

and retain securely each s hroud to its induction

和牢固地保持各hroud其感应

manifold with bolts and spring washers.

带有螺栓和弹簧垫圈的流形。

10 Eliminate air from the high-pressure fuel system

10消除高压燃油系统中的空气

as given on page 27.

如页27。

11 Run the engine and check for leaks.

11运行Perkins3012发动机并检查泄漏。

英国原装珀金斯发电机皮带,原装珀金斯风扇皮带,原装珀金斯充电机皮带,英国珀金斯充电机发电机,英国铂金斯水泵

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska