英国帕金斯柴油发电机组启动马达维修技术资料

英国帕金斯柴油发电机组启动马达维修技术资料

Starter motor

起动马达

To remove and to fit

要删除和以适应

It is not advisable to attempt repairs to the starter

试图修理初学者是不明智的

motor. This work requires specialist equipment and

电机。这项工作需要专门的设备和

knowledge. If starter motor failure occurs, operator’s

知识。如果发生起动电机故障,操作员的

are advised to take advantage of the Perkins service

建议利用帕金斯服务的优势

exchange scheme.

交换方案。

To remove

删除

1 Disconnect the battery.

1断开蓄电池。

2 Make a note of the terminals of the starter motor

2作起动电机端子的说明

assembly and of the cables which are connected to

组装和连接到的电缆

them.

他们。

3 Disconnect the cables from the starter motor

3断开电机的电缆

assembly.

装配。

4 Remove the three bolts and the spring washers and

4拆下三个螺栓和弹簧垫圈

withdraw, carefully, the assembly of the starter motor.

起动电机的装配,退出,小心。

To fit

适合

1 Fit carefully the assembly of the starter motor to the

1小心地将起动电机的总成

flywheel housing and fit the three bolts and the spring

飞轮壳和配合的三个螺栓和弹簧

washers to retain it.

保留的垫圈。

2 Connect the c ables to the correct terminals.

2将C项为正确的终端。

3 Connect the battery.

3连接电池。

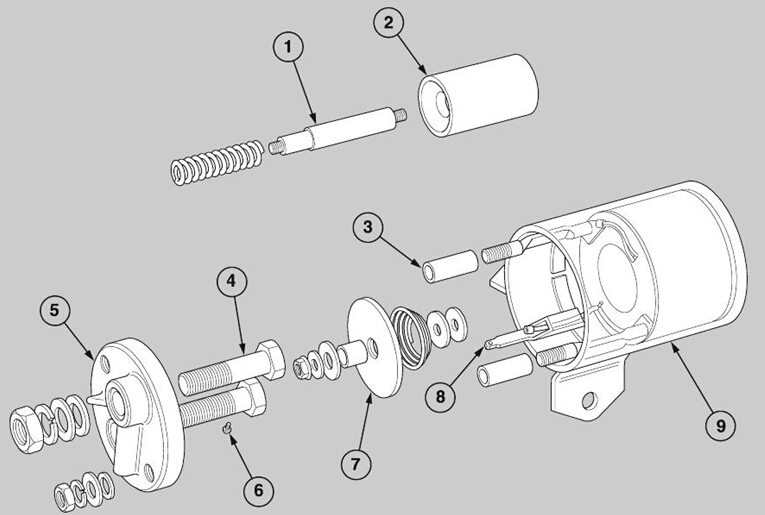

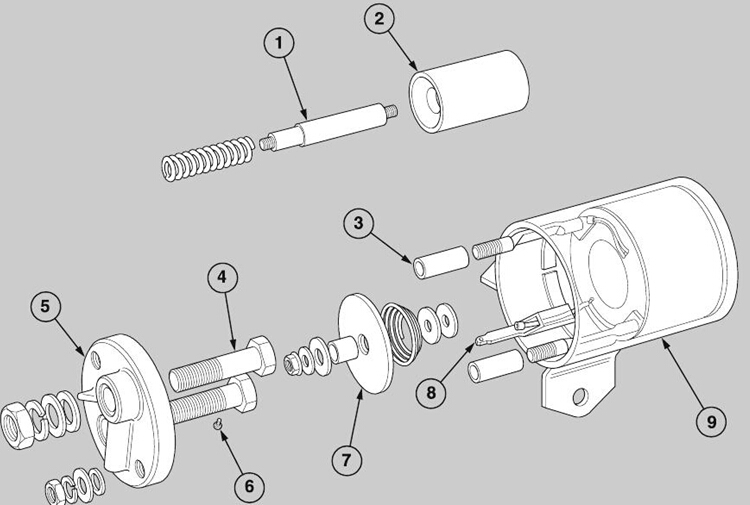

To dismantle

4 Hold the protrusion of the plunger (A2) at the

opposite end of the body (A9) and release the nut

which retains the switch assembly on the shaft (A1).

Remove the washer, the insulation bush, the

contactor disc (A7), the spring, the second insulation

washer and the second washer from the shaft and

withdraw the plunger and the spring from the opposite

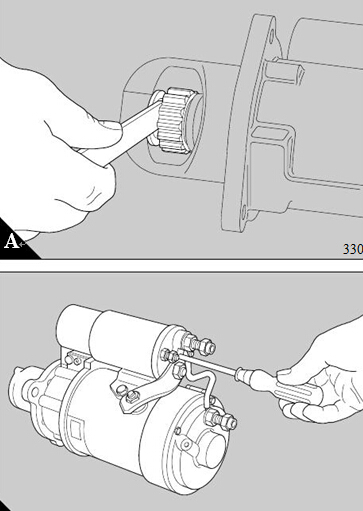

1 Remove both jumper leads from between the

solenoid s witch and the starter body.

A special tool will be needed for the next part of the

operation. The tool can be manufactured from a ¼

inch AF socket; the outside diameter of the socket

must be ground down to 9 mm (0.345 in).

2 Extract the rubber plug from the solenoid base,

insert the special tool, engage it with the timing shaft

and turn it anti-c lockwise until the plunger and arm are

released from the shaft. Unscrew the two retaining

bolts and remove the solenoid switch.

3 Remove the lock nuts, the washers and the sealing

rings from both of the small terminals; partially

withdraw the end cover (A5) and release the small

sc rew (A6) from the head of the terminal (A8) which

retains the connection of the winding. Remove the

end cover (A5) complete with the large terminals (A4),

the lock nuts, the washers and the sealing washers.

Remove also the terminal insulators (A3).

1 Assemble the shaft (A1) and the plunger (A2), if

they have been separated, and fit the spring to the

shaft.

2 Fit the shaft through the body (A9) of the solenoid

switch and fit the washer, the insulation washer, the

spring, the contactor disc (A7), the insulation bush,

the second insulation washer, the washer and the nut

in the correc t sequence as shown (A). Hold the

plunger and tighten the nut.

3 Fit the terminal insulators. Fit the cover to the body

just enough for the small screw (A6) to be fitted

through the connection and into the side of terminal 3.

Fit completely the cover and fit the washers, the

sealing rings and the lock nuts.

4 Fit a new rubber shroud (page 228/A15) to the

housing of the shift lever and ensure that the lip is

engaged fully in the groove.

5 Align the screw link with the threaded hole in the

solenoid plunger (A2) and insert the special tool

through the hole at the centre of the housing. Turn

clockwise the plunger until it reaches the end of the

thread and insert the solenoid switc h in the housing

for the shift lever.

6 Fit the two bolts which fasten the solenoid switch to

the starter motor and tighten them to 34,0 to 39,5 Nm

(300 to 350 lbf in). Turn the plunger anti-clockwise by

approximately five turns.

7 DO NOT fit the flexible cable and the copper

connector until the adjustment of the solenoid is

completed in operation 23-22.

|

To assemble

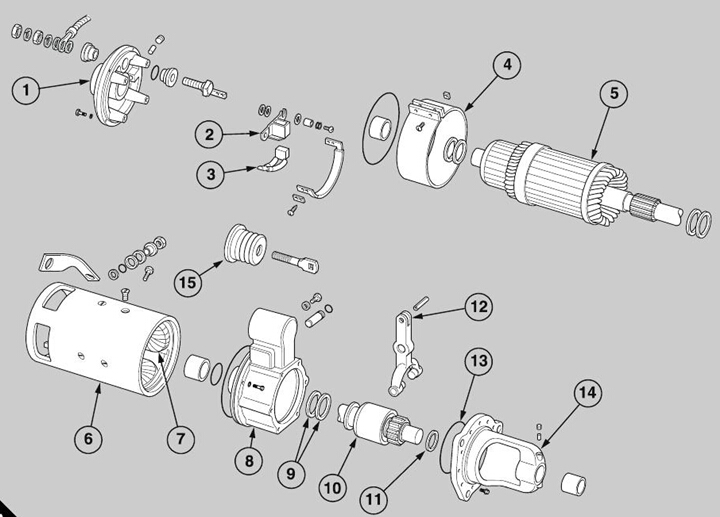

To dismantle

1 Remove the solenoid switc h, operation 23-15.

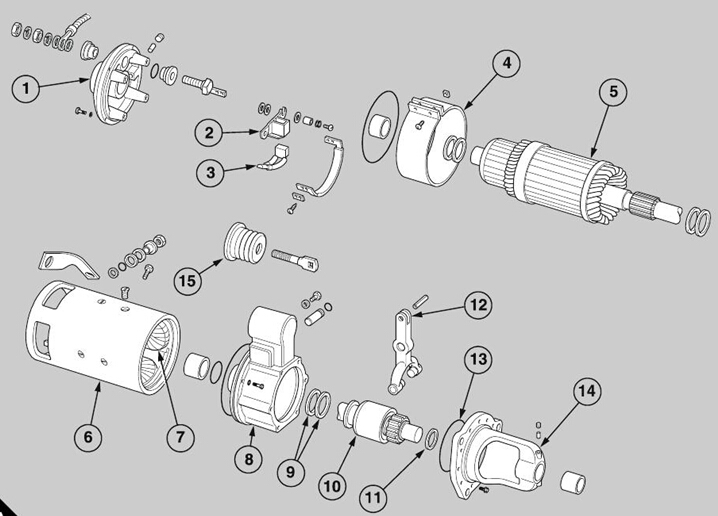

Before the starter motor is dismantled, mark the

edges of each section of the starter motor to ensure

their correct relationship during assembly.

2 Remove the carbon brush cover (A4), release the

connections and carefully withdraw the carbon

brushes (A3).

3 Disconnect the two cables from the field windings

(A7), release the four bolts and remove the end cover

(A1). Withdraw the armature (A5).

4 Release the six c ap screws and remove the pinion

housing (A8); dis connect and remove the pinion

assembly (A10).

5 Remove the screw and washer from the housing

(A8); withdraw the pivot and remove the shift lever

(A12). Separate the housing from the yoke (A6).

Ensure that all the components are clean and dry

before they are assembled. Apply glycerine to the

new ’O’ rings and lubricate all the bushes with clean

SAE 5W/20 engine lubricating oil. Soak the fibre

washers and lubricator wicks in clean SAE 5W/20

engine lubricating oil.

1 Fit a new ’O’ ring around the end cover (A1) and

align the marks which indicate the correct relationship

with the yoke. Put new spring washers on the four

bolts which fasten the end cover to the yoke. Apply

’Loc tite AVV’ to the threads and fit the bolts. Tighten

each bolt to 12,5 to 17 Nm (110 to 150 lbf in).

2 Fit a steel thrust washer, followed by a fibre washer,

on to the armature shaft at the commutator end and

insert the shaft into the yoke assembly. Fit a steel

washer, followed by a fibre washer, onto the splined

end of the shaft and lubricate the shaft and the splines

with ’Aeroshell Grease No. DID 5598’.

3 Fit a new ’O’ ring around the housing (A14) and

apply some grease to the cams of the shift lever.

4 Put the housing (A8) over the protrusion of the shaft

and fit two fibre washers (A9) onto the shaft. Engage

the two cams of the shift lever in the groove of the

pinion assembly and slide the assembly and the

housing onto the shaft. Align the marks which

indicate the correct relationship of the housing and

the yoke, and apply ’Loctite AVV’ to the threads of the

five cap screws. Insert the cap screws, with new

spring washers, and tighten to 12,5 to 17 Nm (110 to

150 lbf in).

5 Fit the steel thrust washer (A11) onto the shaft and

against the pinion assembly. Fit a new ’O’ ring (A13)

to the pinion housing and put the housing around the

pinion. Align the marks which indicate the correct

relationship of the housings for the shift lever and the

pinion. Six new special cap screws, which have a

small square area of locking agent on the threads, are

inserted through the relevant holes of the housing for

the pinion and into the housing for the shift lever.

6 Tighten evenly the cap screws to 24,4 to 28,3 Nm

(216 to 250 lbf in).

7 Check that the armature turns freely, and fit the

carbon brushes into their holders (A2). Ensure that

the carbon brushes slide freely in the holders and

tighten the screws which retain the carbon brushes to

1,6 to 2,0 Nm (14 to 18 lbf in). Check that the wires of

the carbon brushes remain free.

8 Use a spring balance to check the springs of the

carbon brushes. Renew the s prings if the loads are

not within the limits of 1,42 to 1,68 kgf (50 to 59 ozf),

when the end of each spring is held in its correct

position in accordance with the length of a new

carbon brush.

9 Spread a thin application of glycerine on the gasket

of the cover (A4), and fit the ends of the cov er across

one of the ribbed sections of the yoke. Tighten the

two screws which retain the cover to 1,13 to 1,70 Nm

(10 to 15 lbf in).

10 Fit the solenoid switch, operation 23-15.

To clean

6 Inspect the bushes in the end cover of the

Use white spirits to clean all the components. Do

NOT dip the assembly of the pinion in the white

spirits, because the special lubricant in the assembly

will be eliminated.

To inspect and to correct

1 Use an ’Avometer’ to check the resistance of the

winding which pulls the plunger and the winding which

holds the plunger; these should be 1.34 and 2.7 ohms

respectively, at 20°C. Renew the solenoid switch if

the windings are defective.

2 Inspect the assembly of the yoke and the field

windings, and also the housings, of the starter motor

for damage. Use suitable equipment to check the

insulation of the field windings and to check that the

continuity is not broken. Renew the complete

assembly of the yoke and the field windings if any field

winding is defective.

3 Inspect the armature for wear and damage,

especially the splines. Check that there is no

deflection of the shaft. Renew the shaft if the run-out

exceeds 0,13 mm (0.005 in).

4 Use s uitable equipment to check that the continuity

and insulation of the armature windings are not

broken. The commutator should have a polis hed dark

copper finish. Check that the run-out of the

commutator is within 0,08 mm (0.003 in). If the

armature is generally acceptable, the surface of the

commutator may be corrected. Remove only the

minimum material from the face. The final diameter

must not be less than 52,375 mm (2.063 in).

5 Test the insulation of the holders for the carbon

brushes, and renew the carbon brushes if there is

damage or wear. The minimum permis sible length of

the carbon brushes is 15,9 mm (0.625 in).

commutator and in the pinion housing. If there are

indications of wear, use a 13/16 in BSF tapered tap as

a puller to withdraw the old bushes. Press in the new

bushes.

7 Use the measurements of the old bush to machine

a groove in the new bush which aligns with the

lubricator wick.

8 Put the end cover, or the housing for the pinion, in

a lathe and ream the new bush to obtain an internal

diameter of 19,100 to 19,152 mm (0.752 to 0.754 in).

Ensure that there is concentricity of the bore with the

location face of the shoulder.

9 Inspect the bush in the housing of the shift lever. If

necessary, renew the bush, and machine an oil

groove which is the same as the groove in the old

bush. Put the hous ing in a lathe and ensure that there

is concentricity of the bore with the location face of the

shoulder. Bore the new bush to obtain an internal

diameter of 22,200 to 22,250 mm (0.874 to 0.876 in).

10 Ins pect the shift lever and its shaft for wear and

damage, and check that the arrangement which

retains the shaft in the housing is usable.

11 Check that the contactor disc is not burnt and that

there is no erosion. If necessary, clean the contact

face with smooth emery paper, or machine only the

minimum material from the contact face (maximum

0,5 mm (0.002 in)). If the erosion exceeds this limit,

the contactor disc must be renewed.

12 Check the contact faces on the heads of the

terminals. Renew the terminals if they are burnt or if

there is erosion.

13 Inspec t the assembly of the pinion, and renew the

assembly if the components have excessive wear or

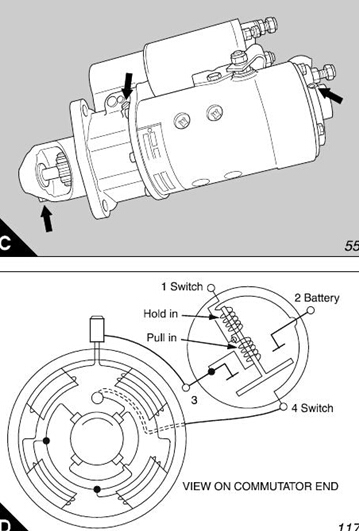

Caution:

Ensure that the 24 volt electrical supply is

connected to the correct terminals and that the

insulation on the connection wires is not damaged.

1 Connect a 24 volt power supply to the terminals 1

and 3 of the solenoid switc h to energise the solenoid.

Push carefully the assembly of the pinion against the

cams of the shift lever. Use the gauge GO 14001 (A)

to check that the gap between the face of the pinion

and the face of the thrust washer is 4,76 mm (0.187

in).

2 If an adjustment is necess ary, de-energise the

solenoid and use the special tool TO 69017 (A) to turn

the shaft of the plunger until the gauge just slides

between the face of the pinion and the face of the

thrust washer.

Caution: Adjustments must not be made while the

solenoid is energised. Do NOT energise the solenoid

for more than 30 seconds.

3 Fit the rubber plug in the hole in the centre of the

housing at the end of the solenoid switch; connect, at

the terminal (4), the flexible cable which is between

the solenoid and the starter motor and also fit the

copper connector.

4 To test the solenoid switch for the correct operating

sequence, proceed as follows:

Fit a locally manufactured solid distance piece to the

pinion shaft to retain the drive and prevent the pinion

gear from moving. Connec t a 24 volt supply across

terminals 1 and 3, and check with an Avometer that

no reading is recorded between terminals 2 and 3 (D).

To fit the main starter cables

以配合主起动器电缆

23-20

对手

Caution: The main positive (red) s tarter cable is

注意:主要阳性(红色)的塔特电缆

fitted to the terminal on the solenoid switch and the

安装在电磁开关上的端子和

main negative (black) starter cable is fitted to the

主要负(黑色)起动器电缆安装

terminal on the end cover of the starter motor.

起动电机端盖端。

1 Fit the lugs of the relevant cables to the two

1符合有关电缆的两耳

terminals. Ensure that the polarity of the cables is

终端。确保电缆的极性

correct and fit the locking washers and the lock nuts,

正确、安装锁紧垫圈和锁紧螺母,

or the stiffnuts if relevant.

如果相关的或刚性螺母。

2 Hold a 19 mm (0.75 in) A/F spanner on the inner

2保持19毫米(0.75英寸)的A / F内扳手

lock nuts to ensure that they do not move while the

锁紧螺母,确保它们不动

outer nuts are tightened to 34 to 41 Nm (25 to 30 lbf

外螺母拧紧至34至41纳米(25至30磅

ft) with a suitable torque wrench.

英尺)用一个合适的扭矩扳手。

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska