⑴P30E机组

⑵P50E1机组

⑶ P330E机组

⑷ P系列防音型

⑸ P系列拖车型

3、威尔信柴油发电机配件功能介绍

㈠控制屏

1001控制屏:⑴仪表:电压表、电流表、频率/转速表、运行时间表、冷却水温表、润滑油压力表、电池电压表

⑵有报警灯的故障停机保护( 高水温、低油压)

⑶控制:开关停机运行/预热/启动、急停按钮、告警测试

2001系列:允许通过遥控信号,自动控制发电机组,因而适用TI系列自动负载切换屏组成市电/发电机组全自动切换系统。

2001控制屏⑴ 仪表:电压表、电流表、频率/转速表、运行时间表、冷却水温表、润滑油压力表、电池电压表。

⑵控制:开关停机运行/预热/启动、急停按钮、告警测试

⑶故障停机保护: 启动失败、高水温、低油压、超速/紧急停机

⑷控制屏遥控信号/触点:遥控急停连接线端、故障警报信号干触点

Access4000控制屏:提供开放的通讯协议具有远程监控,能提供多种操作和保护功能的自启动系统。

Access4000:

⑴ 全数字具有4行超宽的LCD显示发电机组相关工作数据。

⑵ 各种故障报警及停机功能

⑶ 开放通讯接口(R422或R485)

⑷ 失电数据自动存储

⑸ 故障历史数据

⑹ 分级保护控制密码

6200系列控制屏:具有自动并机功能的自启动数码式 控制屏,配合市电失压检测模块(AMF)实现全自动的并车。能做到自动分配有功功率和无功功率,即使机组型号不同,自动负载分配程序也同样能够根据机组的输出能力自动按比例分配负载。

6200控制屏:

⑴ 全数字2×4行LCD显示发电机组相关工作数据

⑵ 各种故障报警及停机功能

⑶ 开放通讯接口(R422或R485)

⑷ 相关系统控制

⑸ 相关操作控制

4、威尔信机组其它功能介绍

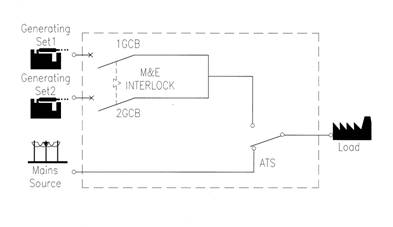

威尔信机组配置2001控制屏及TI/TX的ATS双机备用自动系统(-)

4、威尔信机组其它功能介绍

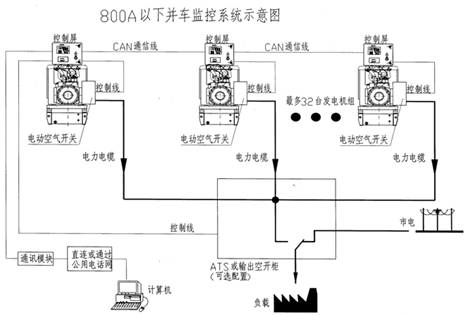

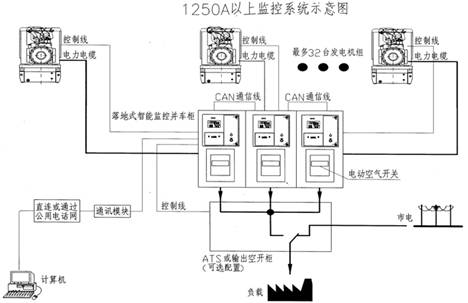

威尔信机组并机系统功能(二)

1.手动和自动控制单台机组的启停及输出空气开关;

2.LCD宽屏液晶参数显示:油压、水温、电池电压、运行时间等油机参数,三相相电压、线电压、线电流、频率、功率因数、有功功率、无功功率、电度等电参数,并联汇流母线电压、母线与发电机电压、频率、相位差等同步参数;

3.发电机组低油压、高水温、超速、超频、速度信号丢失、起动失败、过流、电压过高或过低、逆功率保护停机;

4.发电机组充电失败、水温高、油压低、电池电压低、传感器故障报警;

5.类似黑匣子的历史事件记录;

6.参数设置授权控制;

7.方便功能扩展。

威尔信机组并机系统功能(三)

1.自动并车,自动按设定的比例实现有功和无功负载的无差分配,自动根据负载波动投入和撤出机组,即当负荷较轻时会自动退出部分机组,当负荷较重时会自动投入部分机组 ;

2.实现多台备用时不停电负载转移;

3.启动负载储备及运行负载储备的设定功能。当负荷在任意点反复波动时都不会造成机组 频繁投切,可保证在负载变动时提供稳定的电力;

4.启动优先顺序可编程设定;

5.机组之间通过CAN工业控制器高速总线进行通讯;

6.具有可编程输入/输出口;

7.易于实现单台手动机组扩容为多台监控并机;

8.根据需要方便扩展并机单元,最多可达8台。

9.通过精确设置参数、优化负载管理来达到可靠和经济运行的目的。

威尔信机组并机系统功能(四)

用于并车的机组必须装有电子调速器及自动电压调节装置(AVR),每台并

车机组为一个单元,当负载扩容时可根据需要任意增加并机单元,每个并

机单元包含:

● 6200控制屏

● 自动断路器(MCCB)整个并机系统可以有如下可选配量:

● 输出空气开关柜(ACB柜)(可选)

● 自动电源切换柜(ATS柜)(可选)

柴油发电机组调速器的基本原理和类型

柴油发电机组调速器的基本原理和类型

1. 喷油泵的速度特性

喷油泵每个工作循环的供油量主要取决于调节拉杆的位置。此外,还受到发动机转速的影响。在调节拉杆位置不变时,随着发动机曲轴转速增大,柱塞有效行程略有增加,而供油量也略有增大;反之,供油量略有减少。这种供油量随转速变化的关系称为喷油泵的速度特性。

2. 柴油机上为什么要安装调速器

喷油泵的速度特性对工况多变的柴油机是非常不利的。当发动机负荷稍有变化时,导致发动机转速变化很大。当负荷减小时,转速升高,转速升高导致柱塞泵循环供油量增加,循环供油量增加又导致转速进一步升高,这样不断地恶性循环,造成发动机转速越来越高,最后飞车;反之,当负荷增大时,转速降低,转速降低导致柱塞泵循环供油量减少,循环供油量减少又导致转速进一步降低,这样不断地恶性循环,造成发动机转速越来越低,最后熄火。

要改变这种恶性循环,就要求有一种能根据负荷的变化,自动调节供油量。使发动机在规定的转速范围内稳定运转的自动控制机构。移动供油拉杆,可以改变循环供油量,使发动机的转速基本不变。因此,柴油机要满足使用要求,就必须安装调速器。

3. 调速器的功用、形式

调速器是根据发动机负荷变化而自动调节供油量,从而保证发动机的转速稳定在很小的范围内变化。

型式:按功能分有两速调速器、全速调速器、定速调速器和综合调速器;按转速传感分有气动式调速器、机械离心式调速器和复合式调速器。

4. 机械离心式调速器的工作原理

机械离心式调速器是根据弹簧力和离心力相平衡进行调速的,工作中,弹簧力总是将供油拉杆向循环供油量增加的方向移动;而离心力总是将供油拉杆向循环供油量减少的方向移动。当负荷减小时,转速升高,离心力大于弹簧力,供油拉杆向循环供油量减少的方向移动,循环供油量减小,转速降低,离心力又小于弹簧力,供油拉杆又向循环供油量增加的方向移动,循环供油量增加,转速又升高,直到离心力和弹簧力平衡,供油拉杆才保持不变。这样转速基本稳定在很小的范围内变化。

反之当负荷增加时,转速降低,弹簧力大于离心力,供油拉杆向循环供油量增加的方向移动,循环供油量增加,转速升高,弹簧力又小于离心力,供油拉杆

又向循环供油量减小的方向移动,循环供油量减小,转速又降低,直到离心力和弹簧力平衡。

5. 两速调速器

两速调速器适用于一般条件下使用的汽车柴油机,它只能自动稳定和限制柴油机最低与最高转速,而在所有中间转速范围内则由驾驶员控制。

宁波日兴动力科技有限公司柴油发动机/工程机机械发动机/船舶动力/发电机组整体标准维修作业程序

一:按章施工

本公司对整台发电机的维修,实行程序卡制度,并将整个工作流程分为以下11道工序。

1:发电机拆卸前的检查项目。2:柴油机的拆卸项目。3:柴油机各部件的清洗。4:柴油机各部件的检查及测量。5:柴油机所需更换的配件目录。6:柴油机各部件的装配。7:柴油机装配完毕试机前的检查项目。8:柴油机试机程序的各个检查项目。9:柴油机返修项目。10:柴油机磨合期的各个检查项目。11:柴油机磨合后正常运行交付使用。

二:用户须知

在整个维修过程中,我们要求客户必须配合以下工作。1:客户派出一名主管对整个工程进行监督管理。2:每道工序幸均须由工程总监和客户主管签名作实。3:监督主管在整个工程中,认为施工者不按程序卡进行操作,必须马上予以制止,和维修组长进行交涉。4:若意见分岐,请和本公司营业员联系,直至达到意见统一后方可进行施工。

三:检修程序

A.机体和曲柄连杆机构:1.气缸体的损伤/气缸体常见的损伤有:烧瓦、主轴承孔变形、裂纹、破碎、水道口腐蚀和配合表面磨损等。在外观检查时,应无任何的裂纹和损伤,若发现有导致漏水、漏油、漏气、损伤时,必须予以修理或更换。尤其对气缸体与气缸套接触的密封环带处有无穴蚀、腐蚀现象予以特别检查。2.主轴承孔/对有烧瓦现象的缸体,要特别对主轴承孔孔径予以测量,非标主轴承孔必须予以修正。 3.凸轮轴孔/凸轮轴衬套表面露铜大于120度时,必须更换凸轮轴衬套,如果凸轮轴衬套磨损过度,也必须予以更换,否则会引起机油压力过低,衬套如在座孔中转动,则必须检查座孔的尺寸,超标则修理座孔并换新衬套。4.气缸套座孔/检查气缸厦门座孔的失圆度,不应大于0。025mm,气缸套座孔肩台有无裂纹,气缸套凸出量在0。15-0。20mm之间,新缸套装入缸体后不应有左右摆动的现象。

B. 活塞、活塞环、活塞销组件,

活塞的损坏现象有:1:活塞顶面的烧蚀。2:活塞环槽侧壁的磨损及环岸断裂。3:活塞销孔孔径变大,失圆。4:销座部位裂纹。5:活塞初部拉伤。6:活塞初部磨损和马椭圆。7:活塞环槽内侧有脊峰存在。8:活塞磨损过大。

C.连杆组件

连杆组件的主要损伤有:1:小头衬套磨损。2:小头衬套座孔和大头轴瓦座孔磨损与变形。3:连杆的弯曲的扭曲。4:连杆螺钉或螺杆有裂纹、变长、螺纹磨损或滑扣现象。5:连杆身有划伤现象。6:连杆有烧瓦变形现象。在安装连杆组件时,必须按正确的扭矩参数及正确的步骤进行操作,而且必须对螺杆螺钉进行复检。

警告:安装连杆组件,须由工程总监亲自操作。对于损伤的连杆组件,必须予以报废,否则会引起连杆断裂,击破气缸体,打断曲轴的危险。

D.曲轴、飞轮组件:由轴的主要损伤有:轴颈磨损,曲轴裂纹和断裂,燃瓦而造成的烧蚀。如果曲轴轴颈的失圆度大于0.05mm时,则需磨削曲轴轴颈。对于烧瓦严重的曲轴,由于其金相组织已发生变化,一般不建议再次使用,有裂纹现象的曲轴必须予报废,否则会有断裂的可能。

警告:安装曲轴、飞轮组件、须由工程总监亲自操作,按标准的扭矩和正确的步骤执行,主轴承盖螺钉必须复检。

E.气缸盖和配气机构,1、气缸盖/气缸盖和气缸体接合平面,气门导管孔,气门座圆孔,喷油器孔,冷却水套壁等处,易产生裂纹,可用目检,水压试验进行检查。气缸盖与气缸体接合平面不平时,建议上磨床修理,每次加工量为0.10mm左右,加工极限为1.00mm。喷油器缸套有渗漏或损伤会引起漏水,应对喷油器铜套予以换新。有裂纹的缸盖建议予以报废,否则会引起漏水现象。2、配气机构: 1)气门座圈和气门导管/个别机组的气门座圈和气门导管需予以磨削,磨削量必须正确,否则会引起气门碰撞活塞,气门和气门导管卡死,机油耗量剧增等故障。此工作须由工程总监亲自操作.2)气门弹簧/检查气门弹簧的长度和弹力,弹簧太软会造成气门跳动,使气门和气门座加剧磨损,也会破坏气门正时,气门和活塞发生碰撞。不合格的弹簧必须予以报废。3)气门和气门座圈的研磨/采用研磨膏研磨气门,使气门和气门座圈呈线性接触,所有气门研磨完毕,必须将研磨膏清洗干净(特别注意要将气门导管内的研磨膏清洗干净)。4)气门上下盖/检查有无裂纹,不合格则予以报废。5)凸轮轴/检查凸轮轴的凸轮型面积轴颈处有无裂纹、凹坑、腐蚀、擦伤,检查齿轮有无裂纹、齿断裂或齿面凹坑,不合格则予以报废,否则会引起冒黑烟、功率亏损、击破缸体的危险。6)凸轮从动件/检查从动轴外有无超标,不合格则予以报废。检查滚轮表面有无麻点,转动是否灵活,是否磨损过度,不合格则予以报废。检查滚轮销及销孔是否磨损过度,超标则予以报废。检查随动臂有无裂纹,如有则予以报废。7)气门及喷油器推杆/球头端有无磨损过度,推杆是否失圆,有无弯曲,不合格则则予以报废。8)播臂/检查有无裂纹,与丁字压板的接触凸面有无磨损或损伤,摇臂衬套内径有无超标。检查摇臂轴的磨损,超标则。予以报废9)丁字压板/检查丁字压板孔径有无超标,丁字压板的螺纹是否磨损和损伤,为合格则予以报废。

警告:凸轮从动件为最关键而且容易出问题的配件,需予以特别检查,否则会出现冒黑烟,功率亏损,击破气缸体曲轴的危险。

Diesel generator governor 's basic principle and type

The 1fuel injection pump speed characteristics

Fuel injection pump oil supply amount of each working cycle depends mainly on the control rod position. In addition, but also by the effects of engine speed. In the control rod position unchanged, with the engine crankshaft speed increases, the plunger effective stroke increases slightly, and the amount of oil also slightly increased; conversely, amount of oil was slightly reduced. The oil supply quantity changes with the rotating speed relationship called fuel injection pump speed characteristic.

On 2 diesel engine why install a speed governor

Fuel injection pump speed on multivariate working diesel engine is very bad. When the engine load is changed slightly, resulting in engine speed change. When the load is reduced, high speed, high speed causes the plunger pump the fuel cycle fuel cycle increased, leading to more speed increases further, the vicious spiral, causing the engine speed is more and more high, the last coaster; conversely, when the load is increased, reducing speed reduces speed, causes the plunger pump the fuel cycle reduced, the fuel cycle and leads to further reduction to reduce speed, this constant vicious spiral, causing the engine speed is more and more low, finally stalling.

To change this vicious spiral, requires a according to the change of load, automatically adjust the amount of oil. To keep the engine at given speed range of stable operation of the automatic control mechanism. Mobile fuel rod, can change the cycle of oil production, the rotation speed of the engine is basically unchanged. Therefore, the diesel engine must meet the requirements for use, you must install the governor.

3 governor function, form

The governor is according to engine load changes automatically regulate oil supply, so as to ensure the engine speed is stable in a very small range.

Type: divided by function two speed governor, full speed regulator speed governor, and governor speed sensing; according to a pneumatic governor, mechanical centrifugal governor and compound type speed governor.

4the working principle of mechanical centrifugal governor

Mechanical centrifugal speed governor is according to the spring force and the centrifugal force is balanced speed, work, the force of the spring will always pull rod to supply fuel cycle of increasing direction; and the centrifugal force will always tie rods to reduce oil fuel cycle to move in the direction of. When the load is reduced, rising of rotating speed, the centrifugal force greater than the force of the spring, to reduce fuel rod fuel cycle in the direction of movement, the fuel cycle is reduced, to reduce speed, centrifugal force is less than the force of the spring, and the fuel cycle fuel rod to increase in the direction of movement, the fuel cycle speed increase, rise, until the centrifugal force and the force of the spring balance, fuel rod will remain unchanged. This speed is stabilized basically in a very small range.

Conversely when the load increases, the rotational speed is reduced, the spring force is larger than the centrifugal force, the fuel cycle fuel rod to increase in the direction of movement, the fuel cycle increased, rising of rotating speed, the spring force is smaller than the centrifugal force, fuel rod

And to the fuel cycle decreases in the direction of movement, the fuel cycle is reduced, speed and reduce, until the centrifugal force and spring force balance.

5two speed governor

Two speed governor for general use under conditions of vehicle diesel engine, it can automatic stability and limit of minimum and maximum speed of diesel engine, and in all the intermediate speed range by the pilot control.

Nikko Ningbo power science and technology limited company diesel engine / engineering mechanical engine / ship power / power unit standard repair procedures

A: according to construction

The company of the whole generator repair, execute program card system, and the whole process is divided into the following11 procedures.

1: generator removing before the examination project. The 2: diesel engine disassembly project. 3: diesel engine parts cleaning. 4: diesel engine parts inspection and measurement. 5: diesel engine replacement parts catalog. 6: assemblage of parts of a diesel engine. 7: diesel engine assembly line test before the examination project. 8: diesel engine test procedures of various examination items. 9: diesel engine repair project. 10: diesel engine running-in period various examination items. 11: diesel engine running-in normal work after delivery.

Two: User guidelines

In the repair process, we request the customer to cooperate with the following work. 1: customer sent a supervisor on the project supervision and management. 2: each process shall be required by the director of engineering and to charge customers signed for confirmation. 3: Supervision of the supervisor in the whole project construction, that does not press a program card operation, must immediately be stopped, and repair group representations. 4: if the opinion divergence, and the company please contact the clerk, until it reaches the agreement before construction.

Three: maintenance program

A. body and a crank and connecting rod mechanism:1 cylinder body damage / cylinder common injury: burn tile, main bearing hole deformation, crack, breakage, the mouth of the water channel matching surface corrosion and abrasion. On visual inspection, should be no crack and damage, if found to have lead to water leakage, oil leakage, leakage, damage, it must be repaired or replaced. Especially for the cylinder body and the cylinder sleeve contacts the sealing ring has no pitting, corrosion phenomenon to be special inspection. 2main bearing hole of burning tile / phenomenon of the cylinder, particularly on the main bearing hole of aperture to be measured, non-standard main bearing hole must be corrected. The 3cam shaft hole and the camshaft bushing surfa, ce exposed copper is greater than 120 degrees, must be replaced if the camshaft bushing, camshaft bushing wear is excessive, also must be replaced, otherwise it would cause the engine oil pressure is too low, such as in the base hole bushing rotate, it must be checked seat hole size, exceed the standard, repair seat hole and renewed bush. 4cylinder block bore / check cylinder Xiamen seat hole non roundness, should not be greater than 0. 025mm, cylinder sleeve hole shoulder have no crack, cylinder liner projection in 0. 15-0. Between 20mm, new cylinder is sheathed in the cylinder should not swing phenomenon.

B. piston, piston ring, piston pin assembly,

Piston damage phenomena are: 1: piston top surface ablation. The 2: piston ring groove side wall wear and ring fracture. 3: piston pin hole aperture greatens, out of round. The 4: pin base crack. 5: piston initial strain. 6: early wear and horse ellipse piston. The 7: piston ring groove medial ridge peak exists. 8: piston wear too large.

C. connecting rod assembly

Connecting rod assembly of major injury are: 1: head liner wear. 2: small end bushing seat hole and the big end bearing saddle bore wear and deformation. 3: rod bending distortion. Connecting rod bolt or screw4: crack, variable length, thread wear or slipping buckles. 5: connecting rod body scratch phenomenon. 6: connecting rod has a tile deformation phenomenon. In the installation of connecting rod assembly, must press the correct torque parameters and the correct procedure, and must be inspected for screw screw.

Warning: installing a linkage assembly, shall be determined by the project manager to operate personally. For the damage of connecting rod assembly, must be scrapped, otherwise it will cause the connecting rod fracture, break the cylinder block, crankshaft and the risk of break.

Crankshaft, flywheel assembly: D. from the axis of the main shaft neck injury: abrasion, crack and fracture, burning tile resulting ablation. If the crankshaft out of roundness is greater than 0.05mm, will be grinding crankshaft. For tile serious crankshaft, due to its metallographic structure has changed, is generally not recommended to use again, crack phenomenon of the crankshaft must be scrapped, or there will be the possible fracture.

Warning: installing crankshaft, flywheel assembly, shall be determined by the project director in person operation, according to the criteria of the torque and the correct steps, main bearing cover screws must recheck.

E. cylinder cover and a gas distribution mechanism,1, cylinder head and cylinder cover and the cylinder body joint plane, valve guide hole, the valve seat hole, the injector hole, water cooling wall, easy to crack, available visual inspection, pressure test check. The cylinder cover and the cylinder body joint planes are not usually, advice on grinding machine repair, each processing capacity of around 0.10mm, processing limit is 1.00mm. The injector cylinder leakage or damage will cause the water leakage, deal with the fuel injector copper sets to be renewed. Cracked cylinder head suggested to be scrapped, otherwise it will cause the water leakage phenomenon. 2, gas distribution mechanism:1) the valve seat and the valve guide / individual units of the valve seat and the valve guide should be grinding, grinding amount must be correctly, otherwise it will cause impact piston valve, valve and valve catheter blocked, oil consumption increases fault. This work is required by the project director personally operation .2) valve spring / check valve spring length and elastic, soft spring will result in valve beating, the valve and valve seat exacerbates wear, will also destroy the valve timing, valve and piston collisions. Unqualified spring must be scrapped. 3) valve and valve seat ring polishing / grinding paste grind the valve, the valve and valve seat ring a linear contact, all valve grinding is finished, must be grinding paste clean (with particular attention to the valve catheter within the grinding paste clean ). 4) valve upper cover and a lower cover / check have no crack, failure will be scrapped. 5) the camshaft / check camshaft type cam shaft neck area of any crack, dent, corrosion, abrasion, check the gear has no cracks, tooth fracture or tooth surface pits, unqualified will be scrapped, otherwise it will cause a black smoke, power loss, the risk of breaking cylinder. 6) the cam follower / check the driven shaft and not exceed the standard, unqualified will be scrapped. Check the wheel surface is pitted, rotation is flexible, whether the excessive wear and tear, unqualified will be scrapped. Check the wheel pin and a pin hole is worn, exceed the standard will be scrapped. Check with the boom has no cracks, such as there is to be scrapped. 7) valve and fuel injector push rod / ball end without excessive wear and tear, the push rod is losing a round, there is no bending, unqualified then will be scrapped. 8) an arm / check for cracks, and the T-shaped plate contact convex are worn or damaged, rocker arm bushing diameter not exceed the standard. Check the arm shaft wear, exceed the standard criterion. Be scrapped9) T-shaped plate / check T-shaped plate aperture having no exceed the standard, the T-shaped plate thread for wear and damage, as qualified will be scrapped.

Warning: the cam follower is the key and difficult parts, need to be special examination, otherwise there will be a black smoke, power loss, breaking cylinder crankshaft risk.